Helical spring with arc center line and independent suspension structure

A helical spring and center line technology, applied in the field of suspension, can solve the problems of uneven force on the helical spring, surface wear, abnormal noise, etc., and achieve the effect of eliminating wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention are described in detail below through the examples. The following examples are only exemplary and can only be used to explain and illustrate the technical solutions of the present invention, but cannot explain and illustrate the limitations of the technical solutions of the present invention.

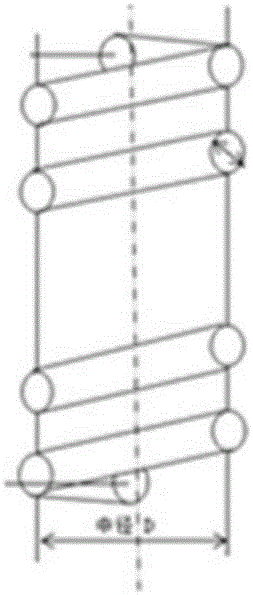

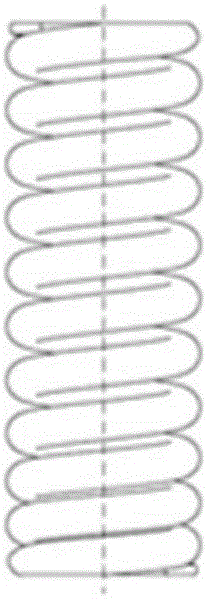

[0033] This application provides a coil spring with a circular arc centerline, such as Figure 8 and Figure 9 As shown, it includes a helical spring body, the centerline of which is a straight line 41, and a curved section helical spring is arranged at the lower end of the helical spring body, and the centerline of the curved section helical spring is an arc-shaped curve 42.

[0034] The present application also provides an independent suspension structure, such as Figure 6 and Figure 7 As shown, it includes the coil spring 4 of the previous item, and also includes a subframe 1, a lower swing arm bushing 2, a lower swing arm 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com