Energy-saving and environment-friendly milling screening machine

An energy-saving and environmental-friendly screening machine technology, applied in grain processing, etc., can solve the problems of increasing equipment and labor input costs, affecting the life of the whole machine, and being unable to continue production, so as to improve material utilization, facilitate mass production, and reduce over-production. The effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

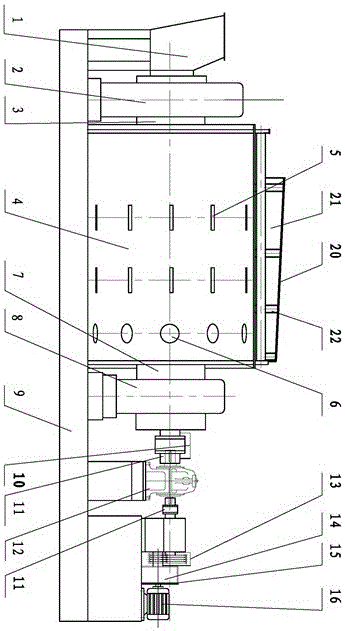

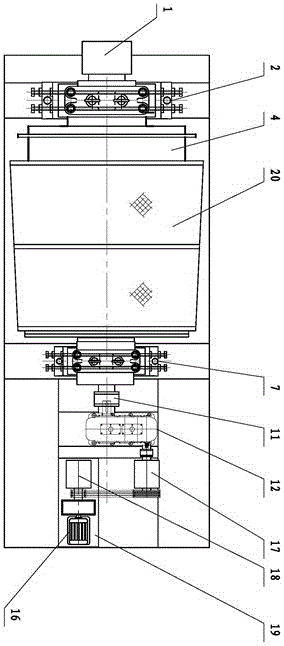

[0021] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

[0022] Such as Figure 1-Figure 3 Shown is an energy-saving and environment-friendly grinding and screening machine of the present invention, which includes a feeding part 1, a cylinder body 4 with a lining plate 23 inside, and a driving device. The feeding part 1 is connected to the cylinder body 4 through a hollow shaft 3 , the cylinder 4 is connected to the driving device through the transmission shaft 7, and the driving device includes the first bearing part 2, the second bearing part 8 and the coupling 11, the speed reducer 12, the first pulley 17, the first Two pulleys 18, a fluid coupling 14 and an electric motor 16. The cylinder mouth of the cylinder 4 away from the feeding part 1 is sealed, and the cylinder 4 is provided with a slender discharge hole 5, and the cylinder 4 is also provided with a screen 20, and the screen 20 is surroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com