Vitamin and mineral nutritive grease for pets and preparation method thereof

A technology of vitamins and minerals, applied in the direction of additional food elements, applications, animal feed, etc., can solve problems such as difficult absorption and poor palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

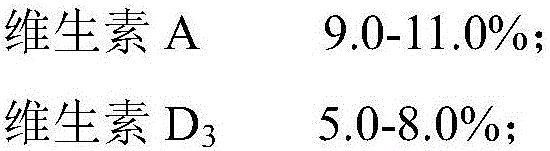

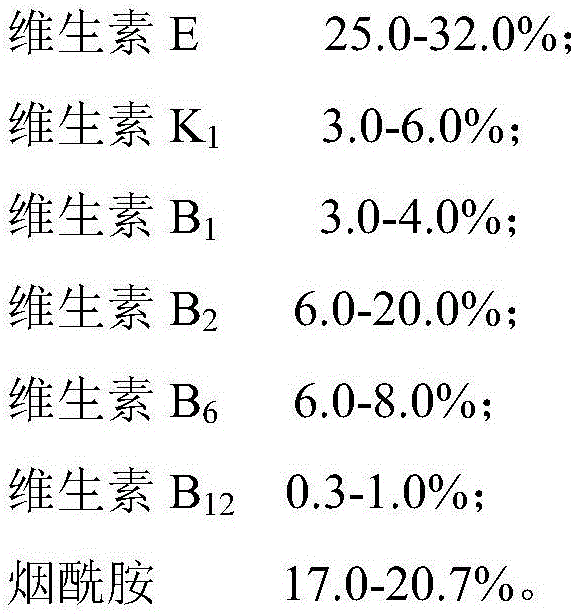

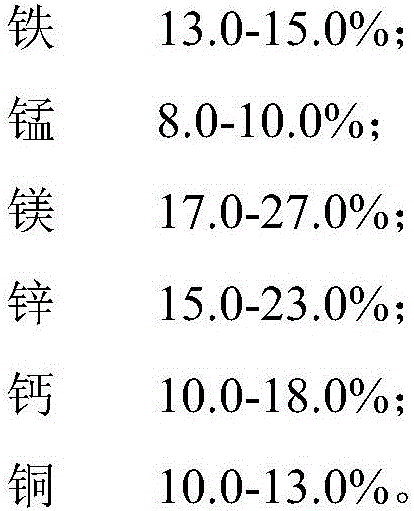

[0058] The total weight of raw materials is 100kg. Among them, vitamin components 18.50kg, mineral components 2.50kg, lecithin 12.50kg, Tween-80+Span-80 20.00kg, chicken liver powder 5.00kg, purified water 41.50kg, of which vitamin A palmitate 2.03 kg, vitamin D 3 Acetate 1.48kg, vitamin E acetate 5.92kg, vitamin K 1 1.11kg, vitamin B nitrate 1 740g, vitamin B 2 Sodium -5 Phosphate 1.85kg, Vitamin B Hydrochloride 6 1.48kg, vitamin B 12 185g, 3.70kg of nicotinamide, including 375g of ferrous sulfate, 250g of manganese sulfate, 675g of magnesium sulfate, 575g of zinc sulfate, 300g of calcium gluconate, and 325g of anhydrous copper sulfate.

Embodiment 2

[0060] The total weight of raw materials is 100kg. Among them, 22.00kg of vitamin components, 2.75kg of mineral components, 13.5kg of lecithin, 25kg of Tween-80, 7.5kg of pork powder, 29.25kg of purified water, of which 2.42kg of vitamin A palmitate, vitamin D 3 Acetate 1.76kg, vitamin E acetate 7.04kg, vitamin K 1 1.32kg, vitamin B nitrate 1 880g, vitamin B 2 Sodium -5 Phosphate 2.20kg, Vitamin B Hydrochloride 6 1.76kg, vitamin B 12 220g, 4.40kg of nicotinamide, including 413g of ferrous sulfate, 275g of manganese sulfate, 742g of magnesium sulfate, 633g of zinc sulfate, 330g of calcium gluconate, and 357g of anhydrous copper sulfate. Example 3

Embodiment 3

[0061] The total weight of raw materials is 100kg. Among them, 25.00kg of vitamin components, 3.00kg of mineral components, 15kg of lecithin, 29.5kg of Span-80, 10kg of fish meal, 17.5kg of purified water, of which 2.75kg of vitamin A palmitate, vitamin D 3 Acetate 2.00kg, vitamin E acetate 8.00kg, vitamin K 1 1.50kg, vitamin B nitrate 1 1.00kg, vitamin B 2 Sodium -5 Phosphate 2.50kg, Vitamin B Hydrochloride 6 2.00kg, vitamin B 12 250g, niacinamide 5kg, including 450g ferrous sulfate, 300g manganese sulfate, 810g magnesium sulfate, 690g zinc sulfate, 360g calcium gluconate, 390g anhydrous copper sulfate. Note: the combination components in all the above examples are mixed in a mass ratio of 1:1.

[0062] Preparation Process:

[0063] 1. Combine vitamins A, D, E, K 1 Weigh and put into the homogeneous emulsifier tank according to the formula ratio.

[0064] 2. Turn on the heating switch of the homogeneous emulsifier, heat the product obtained in step (1) to 80°C whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com