Preparation method of carbon/nickel oxide resistive memory thin film

A technology of resistive memory and nickel oxide, applied in electrical components and other directions, can solve the problems of high erasing voltage, slow memory erasing and writing speed, etc., and achieve the effects of low preparation cost, easy control, and improved preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

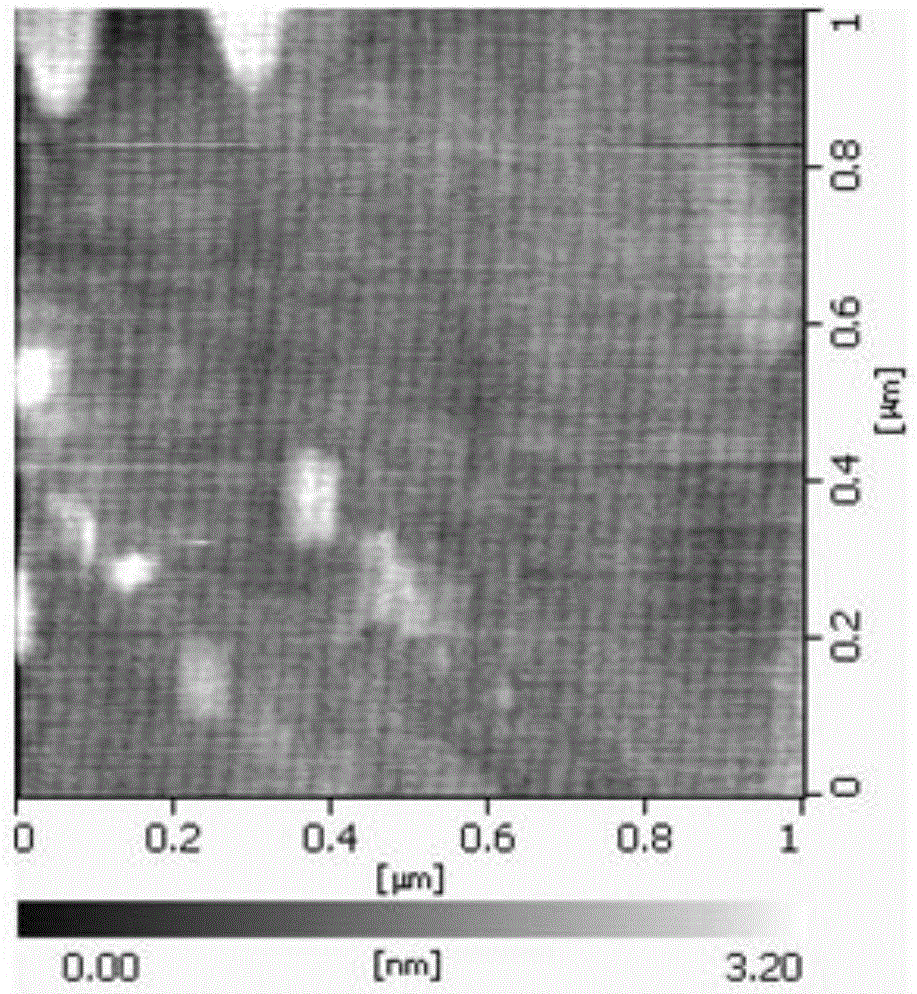

[0035] Step 1: Weigh nickel acetate, acetylacetone, acrylic acid and ethylene glycol methyl ether respectively according to the dosage ratio of 1:1:1:12. After mixing, nickel oxide sol is obtained; at room temperature, adopt dipping-pulling method, Use a pulling machine to pull the nickel oxide gel film on the Pt platinum electrode substrate, dry the nickel oxide gel film at room temperature, bake it at 60°C for 10min, and then bake it at 300°C Heat treatment at high temperature for 20 minutes, and then take it out and cool it down to room temperature naturally, so as to obtain the nickel oxide film on the Pt platinum electrode substrate.

[0036] Step 2: Preparation of carbon / nickel oxide composite film: Place the nickel oxide film obtained in step 1 on the support of the vacuum evaporation apparatus and fix it, then fix a carbon rope with a purity of 99%, a diameter of 2 mm, and a length of 1 cm on the carbon. On the evaporation source; turn on the power of the vacuum evapor...

Embodiment 2

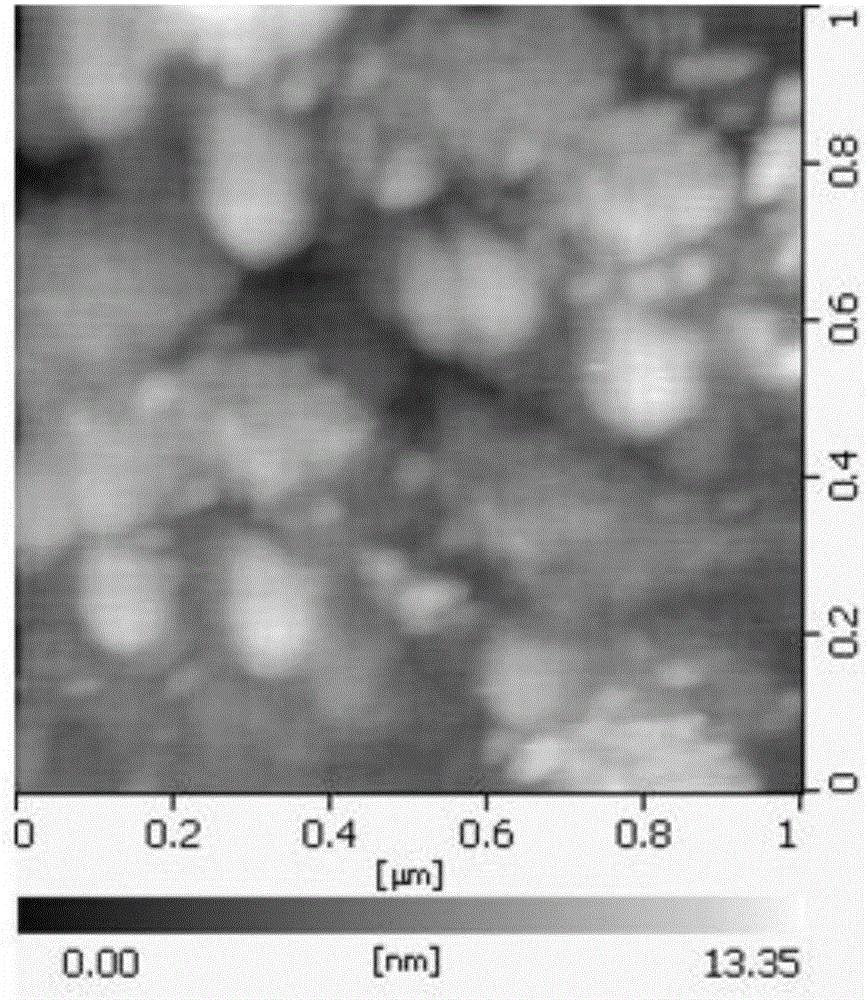

[0040] Step 1: Weigh nickel acetate, acetylacetone, acrylic acid and ethylene glycol methyl ether respectively according to the dosage ratio of 1:1:1:12. After mixing, nickel oxide sol is obtained; at room temperature, adopt dipping-pulling method, Use a pulling machine to pull the nickel oxide gel film on the Pt platinum electrode substrate, dry the nickel oxide gel film at room temperature, bake it at 70°C for 13min, and then bake it at 500°C Heat treatment at high temperature for 25 minutes, and then take out and cool naturally to obtain a nickel oxide film on the Pt platinum electrode substrate.

[0041] Step 2: Preparation of carbon / nickel oxide composite film: Place the nickel oxide film obtained in step 1 on the support of the vacuum evaporation apparatus and fix it, then fix a carbon rope with a purity of 99%, a diameter of 2 mm, and a length of 1 cm on the carbon. On the evaporation source; turn on the power of the vacuum evaporation apparatus, adjust the current of t...

Embodiment 3

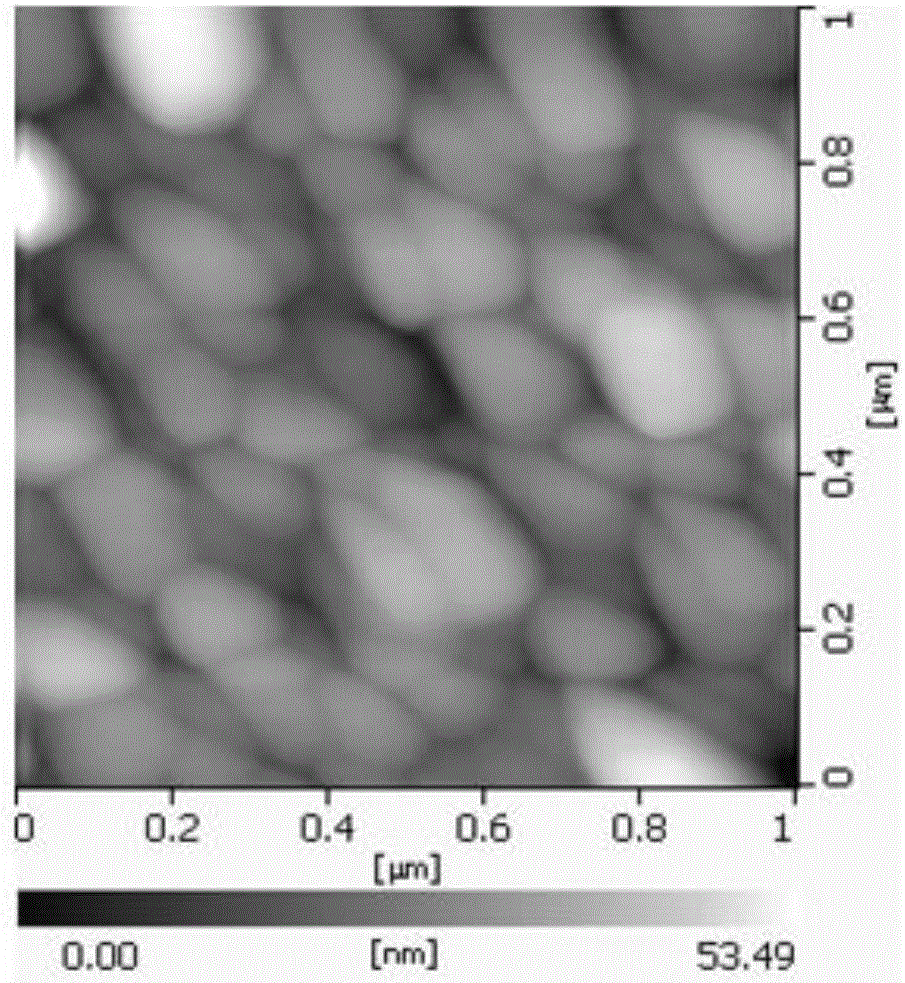

[0045] Step 1: Weigh nickel acetate, acetylacetone, acrylic acid and ethylene glycol methyl ether respectively according to the dosage ratio of 1:1:1:12. After mixing, nickel oxide sol is obtained; at room temperature, adopt dipping-pulling method, Use a pulling machine to pull the nickel oxide gel film on the Pt platinum electrode substrate, dry the nickel oxide gel film at room temperature, bake it at 80°C for 15min, and then bake it at 700°C Heat treatment at high temperature for 30 minutes, then take it out and cool it down to room temperature naturally to obtain a nickel oxide film on the Pt platinum electrode substrate.

[0046] Step 2: Preparation of carbon / nickel oxide composite film: Place the nickel oxide film obtained in step 1 on the support of the vacuum evaporation apparatus and fix it, then fix a carbon rope with a purity of 99%, a diameter of 2 mm, and a length of 1 cm on the carbon. On the evaporation source; turn on the power of the vacuum evaporation apparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com