Preparation method for cold plasma nitrogen-doped carbon fibers

A nitrogen-doped carbon fiber, cold plasma technology, used in fiber processing, textiles and papermaking, physical processing, etc., can solve the problems of small effective specific surface area, inability of internal materials to contact electrolytes, and few active sites, etc. Good stability, high nitrogen doping, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

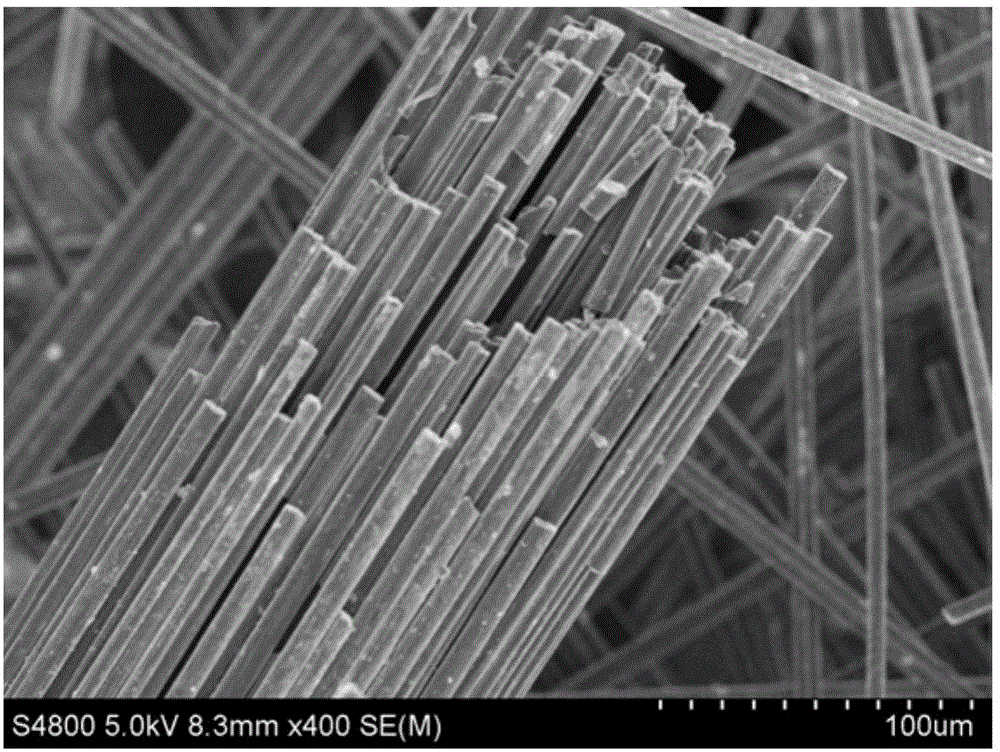

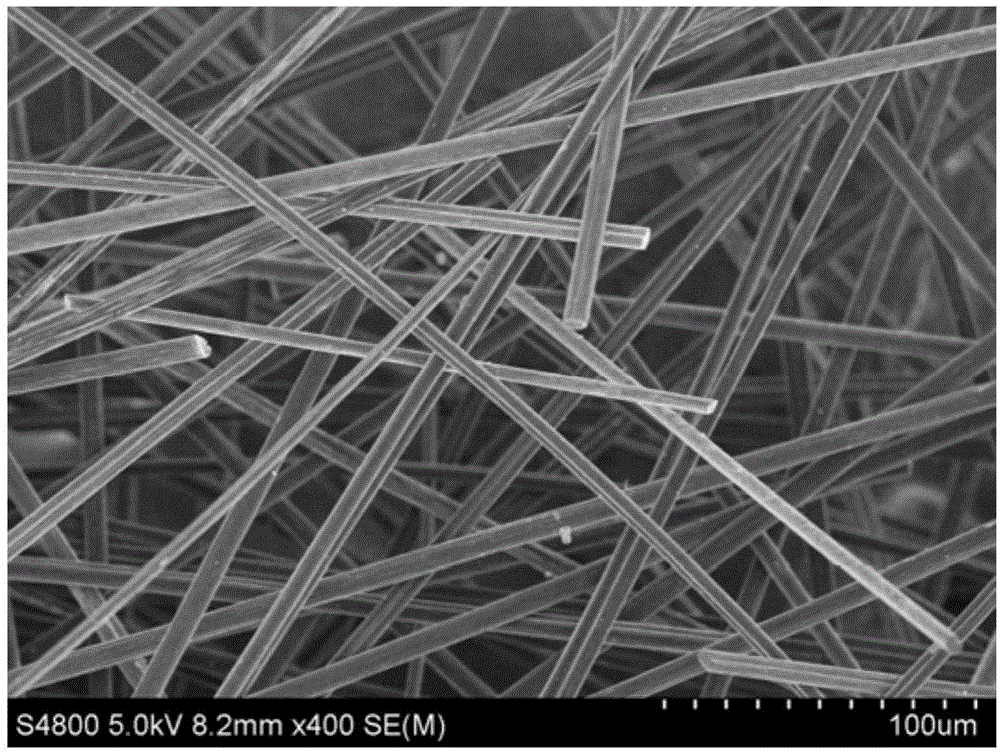

[0015] (1) Put 1 g of commercially available chopped carbon fiber in an atmosphere furnace and keep it warm at 450°C for 30 minutes to obtain heat-treated carbon fiber.

[0016] (2) Add the heat-treated carbon fibers obtained in step (1) to 100 mL of 20% H 2 o 2 Oxidation in medium for 10 hours to obtain oxidized carbon fibers.

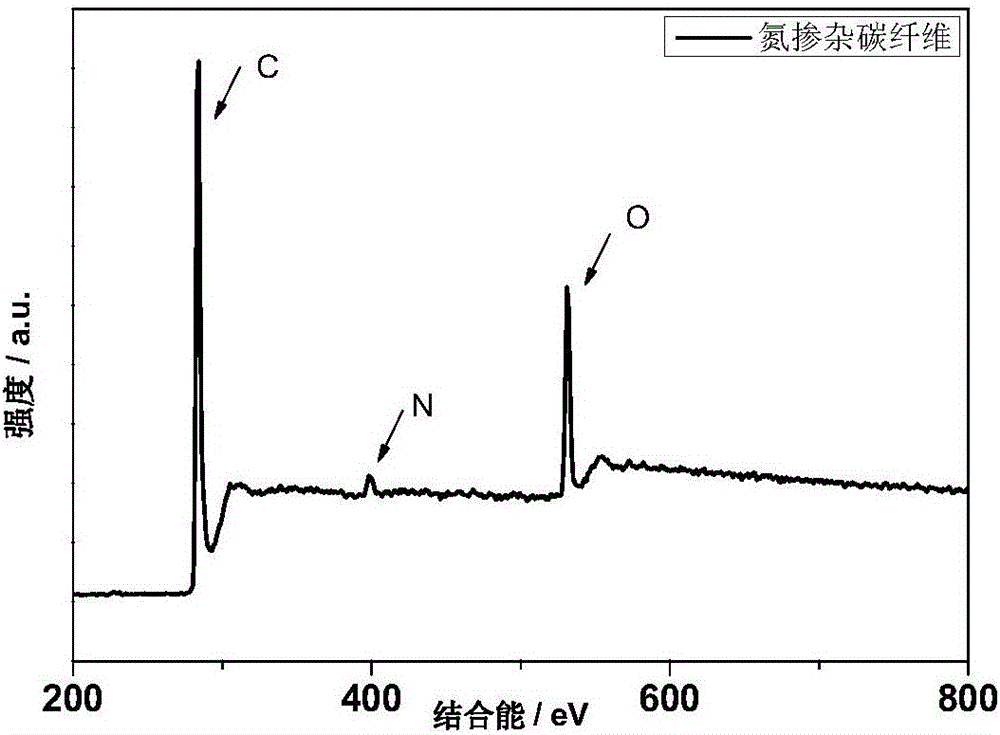

[0017] (3) the carbon oxide fiber obtained in step (2) is placed in N 2 In the atmosphere cold plasma generator, the gas flow rate was 3 L / min, nitrogen doping treatment was performed at 10 W for 60 minutes, and nitrogen doped carbon fibers were obtained.

Embodiment 2

[0019] (1) Put 1 g of commercially available chopped carbon fibers in an atmosphere furnace and keep them warm at 450°C for 35 minutes to obtain heat-treated carbon fibers.

[0020] (2) Add the heat-treated carbon fibers obtained in step (1) to 100 mL of 30% H 2 o 2 Medium oxidation for 24 hours to obtain oxidized carbon fibers.

[0021] (3) the carbon oxide fiber obtained in step (2) is placed in N 2 In the cold atmosphere plasma generator, the gas flow rate was 2 L / min, nitrogen doping treatment was performed at 30 W for 60 minutes, and nitrogen doped carbon fibers were obtained.

Embodiment 3

[0023] (1) Put 1 g of commercially available chopped carbon fibers in an atmosphere furnace and keep them warm at 450°C for 20 minutes to obtain heat-treated carbon fibers.

[0024] (2) Add the heat-treated carbon fibers obtained in step (1) to 100 mL of 30% H 2 o 2 Medium oxidation for 15 hours to obtain oxidized carbon fibers.

[0025] (3) Place the oxidized carbon fibers obtained in step (2) in NH 3 In the atmosphere cold plasma generator, the gas flow rate was 4 L / min, nitrogen doping treatment was performed at 20 W for 45 minutes, and nitrogen doped carbon fibers were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com