Tracked vehicle road wheel hanging glue and preparation method thereof

A road wheel and vehicle technology, which is applied in the field of tracked vehicle road wheel coating and its preparation, can solve problems such as complex components of coating and poor mechanical properties of coating, achieve excellent protection, improve mechanical properties, and prevent excessive The effect of vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

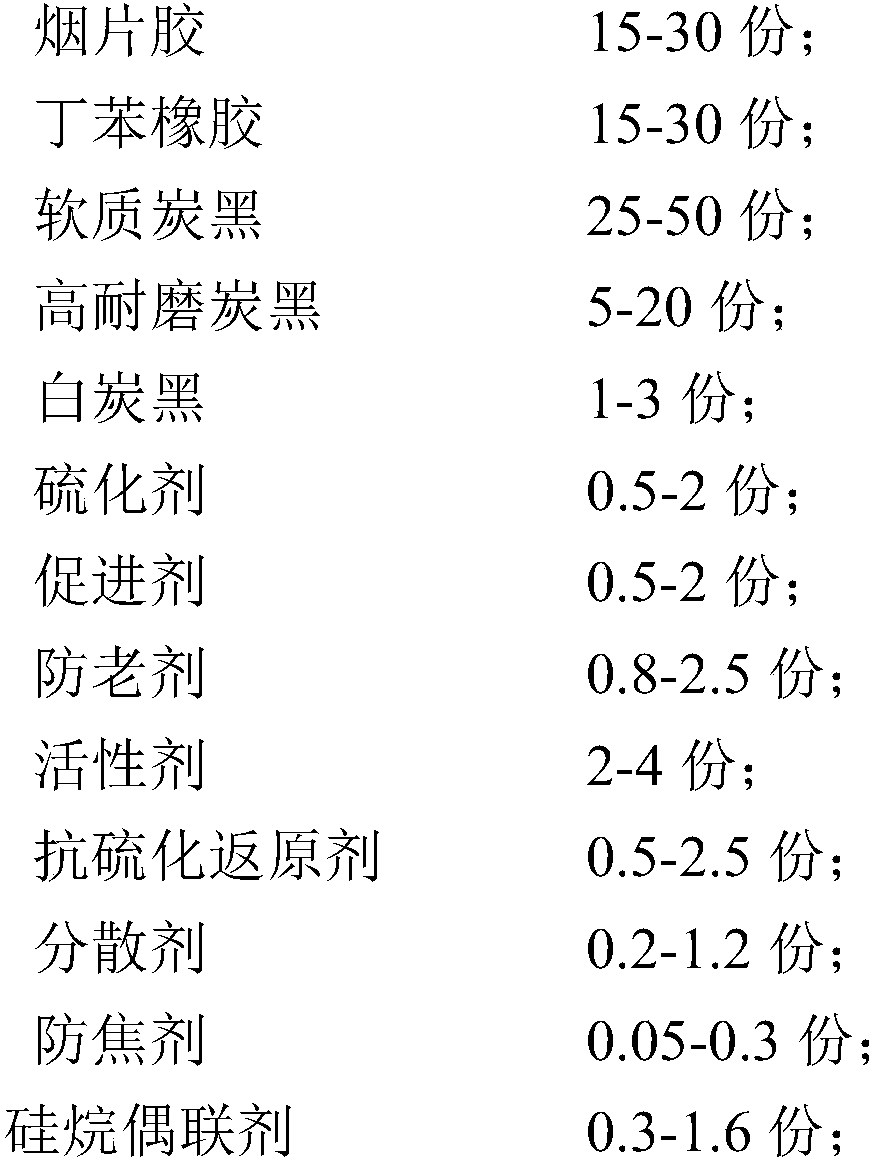

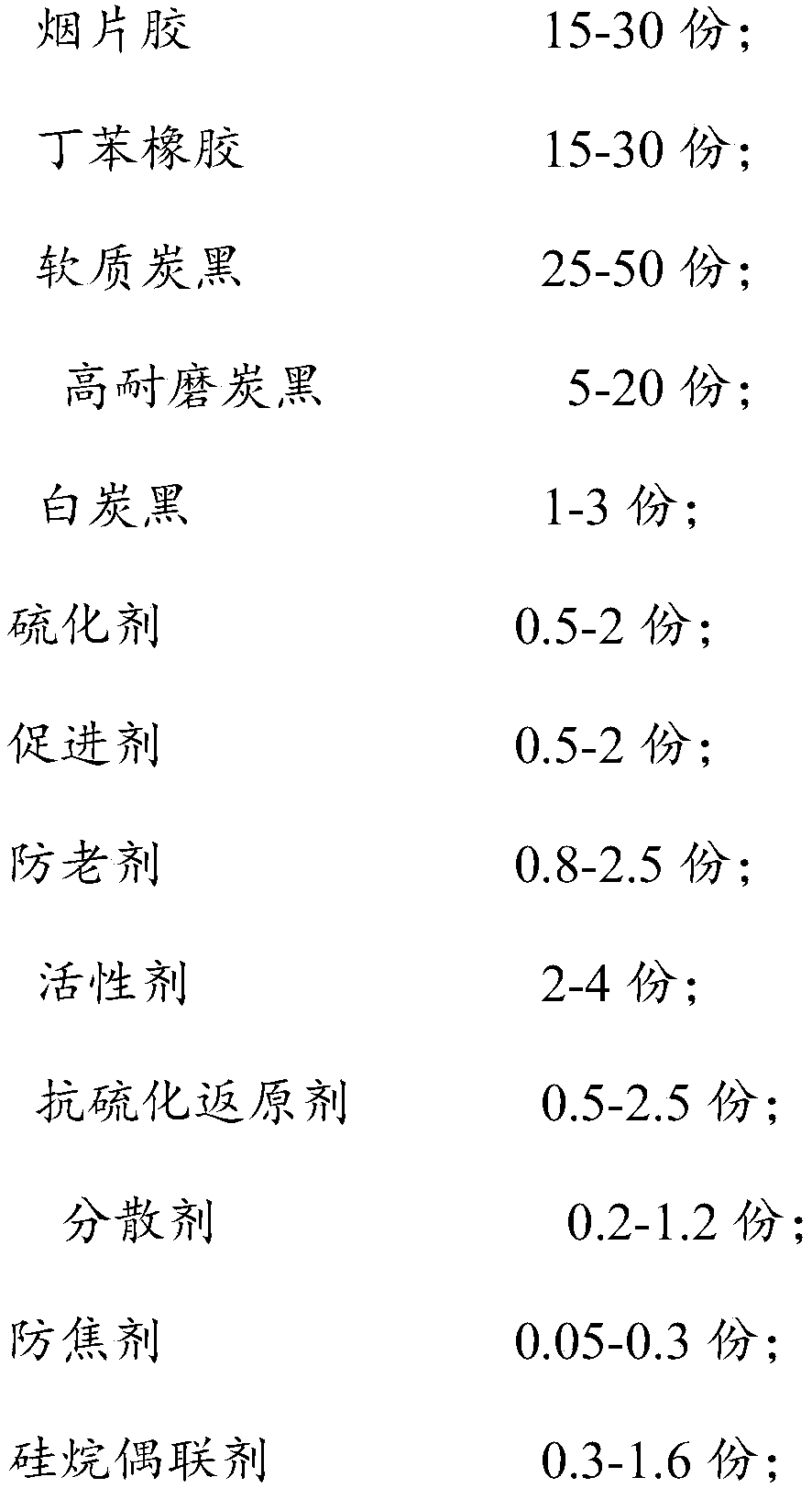

Method used

Image

Examples

Embodiment 1

[0024] A preparation method for tracked vehicle road wheel hanging glue, which comprises the following steps:

[0025] (1) Surface treatment of N339: silane coupling agent KH-550 and silane coupling agent KH-560 with a mass ratio of 3:2 are prepared into an ethanol solution with a mass percentage concentration of 1.5%, and then the high wear-resistant carbon black Add N339 into the stirring tank, spray 15 g of the ethanol solution with 1 kg of high wear-resistant carbon black N339 at a speed of 40 rpm, continue to maintain a speed of 40 rpm for 30 minutes, and finally bake at a temperature of 80 ° C for 30 minutes to obtain The high wear-resistant carbon black through surface treatment;

[0026](2) Preparation of hanging glue: Put 20 parts of 1# smoked sheet rubber and 15 parts of SBR1500 styrene-butadiene rubber into the internal mixer for 15 minutes of internal mixing, then add 1 part of accelerator, 1.5 parts of anti-aging agent, and 3 parts of active agent , 0.5 parts of ...

Embodiment 2

[0029] A preparation method for tracked vehicle road wheel hanging glue, which comprises the following steps:

[0030] (1) Surface treatment of N339: silane coupling agent KH-550 and silane coupling agent KH-560 with a mass ratio of 3:2 are prepared into an ethanol solution with a mass percentage concentration of 1.5%, and then the high wear-resistant carbon black Add N339 into the stirred tank, spray 15g of the ethanol solution with 1kg of high wear-resistant carbon black N339 at a speed of 50rpm, continue to maintain a speed of 50rpm for 45min, and finally bake at a temperature of 100°C for 45min to obtain The high wear-resistant carbon black through surface treatment;

[0031] (2) Preparation of hanging glue: put 23 parts of 1# smoked sheet rubber and 22 parts of SBR1500 styrene-butadiene rubber into the internal mixer for 15-30min banburying, then add 0.9 parts of accelerator, 1 part of anti-aging agent, 2 parts of Active agent, 1.7 parts of anti-reversion agent, 0.8 part...

Embodiment 3

[0034] A preparation method for tracked vehicle road wheel hanging glue, which comprises the following steps:

[0035] (1) Surface treatment of N339: silane coupling agent KH-550 and silane coupling agent KH-560 with a mass ratio of 3:2 are prepared into an ethanol solution with a mass percentage concentration of 1.5%, and then the high wear-resistant carbon black Add N339 into the stirred tank, spray 15g of the ethanol solution with 1kg of high wear-resistant carbon black N339 at a speed of 60rpm, continue to maintain a speed of 60rpm for 60min, and finally bake at a temperature of 120°C for 60min to obtain The high wear-resistant carbon black through surface treatment;

[0036] (2) Preparation of hanging glue: put 30 parts of 1# smoked sheet rubber and 25 parts of SBR1500 styrene-butadiene rubber into the internal mixer for 15-30min banburying, then add 0.6 parts of accelerator, 0.8 parts of anti-aging agent, 2 parts of Active agent, 0.8 parts of anti-reversion agent, 0.5 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com