Method for preparing trimanganese tetroxide with micro-nanostructure

A technology of trimanganese tetraoxide and micro-nano structure, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problem of low specific surface area of trimanganese tetraoxide, and achieve the effects of low pollution, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

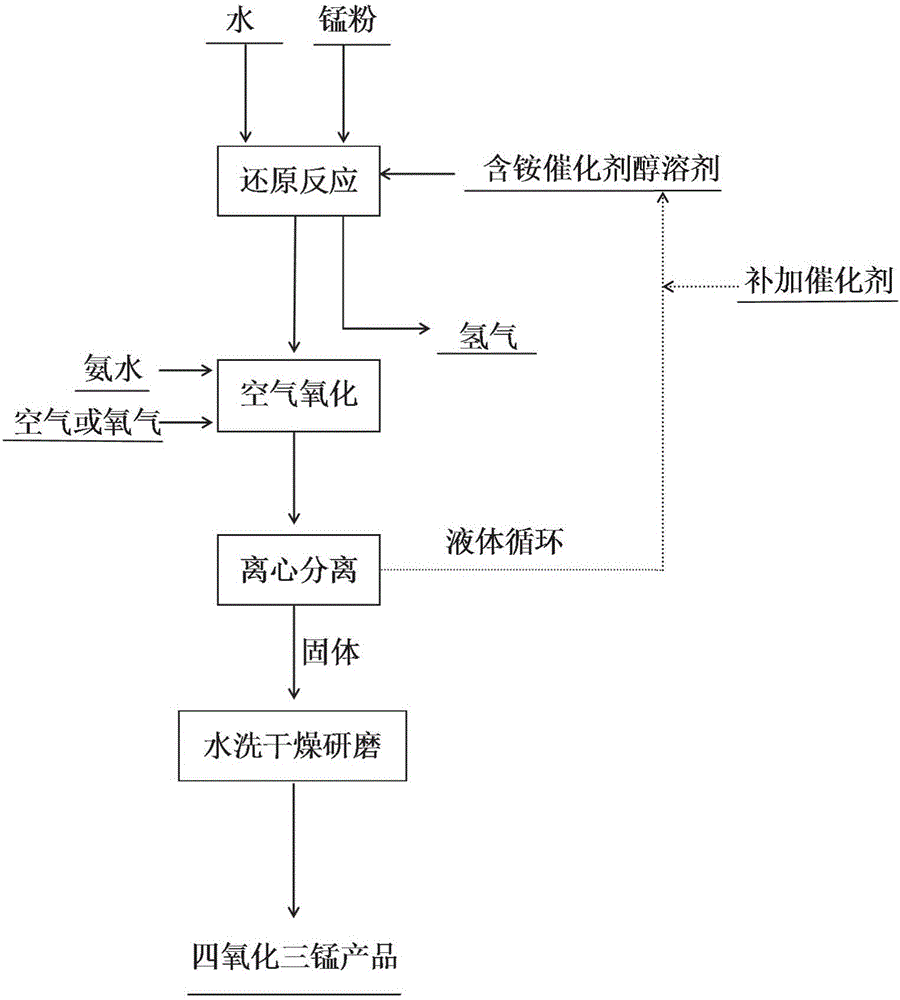

Method used

Image

Examples

Embodiment 1

[0067] Add 1 part of manganese powder to 200 parts of ethanol at 40°C, add 1.4 parts of ammonium acetate catalyst, add 10 parts of distilled water and stir for 12 hours, adjust the pH to 7-9, and stir with air for 5 hours: centrifuge, wash, dry, grind After getting the product. The yield of trimanganese tetraoxide obtained was 99%.

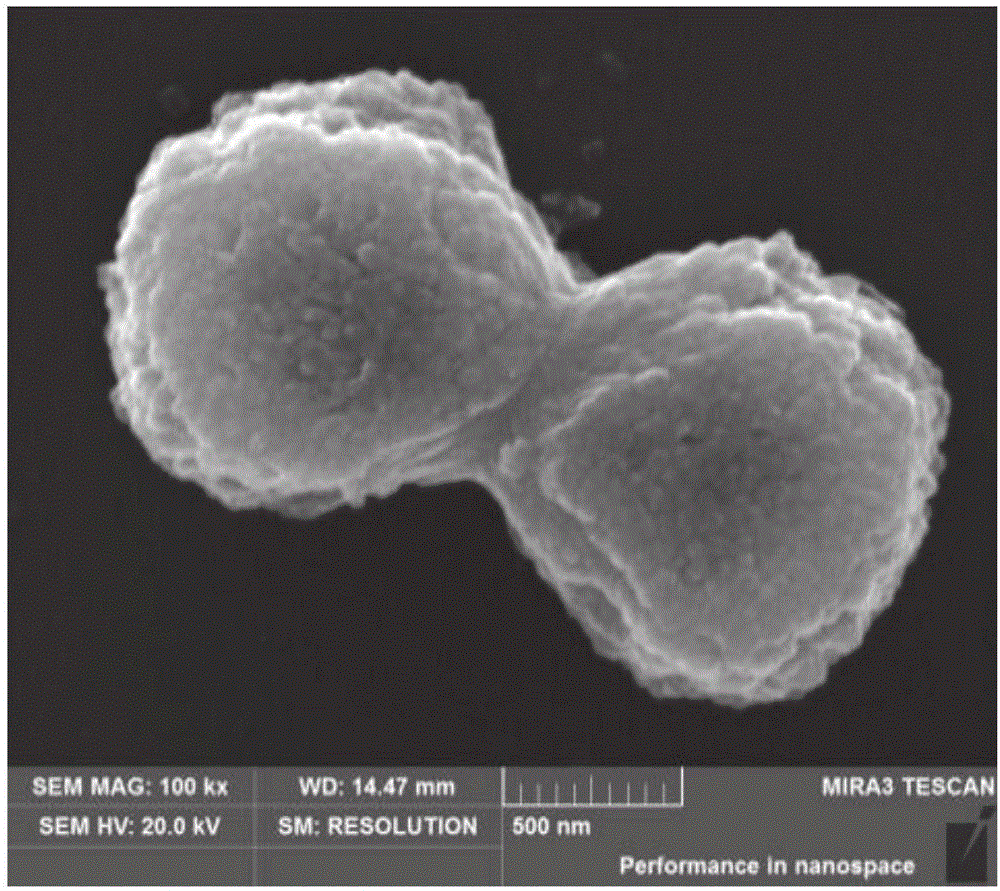

[0068] The product has been tested and the specific surface area of the manganese tetraoxide product is 103.3m 2 / g, Mn element content 71.30%, CaO content 0.0008%, K content 0.0007%, Na content 0.0025%, S content 0.0050%. The scanning electron microscope and transmission electron microscope photos of the product are shown in Figure 2. It can be seen from Figure 2 (a), (b) and (c) that the trimanganese tetraoxide product is a hollow dumbbell structure, and Figure 2 (d) can be seen that the product is made of 10 ~ 15nm grain composition. XRD spectrum and Mn of trimanganese tetraoxide 3 o 4 The standard diffraction pattern of Figure 5 shown...

Embodiment 2

[0070] Add 5 parts of manganese powder to 180 parts of ethanol at 80~~85°C, add 8 parts of ammonium acetate catalyst, add 30 parts of distilled water and stir for 9 hours, adjust the pH to 7~9, and stir with air for 5 hours; centrifuge, wash, and dry The product is obtained after drying and grinding. The yield of trimanganese tetraoxide obtained was 99%.

[0071] The product has been tested and the specific surface area of the manganese tetraoxide product is 84.5m 2 / g, Mn element content 70.50%, CaO content 0.0010%, K content 0.0006%, Na content 0.0020%, S content 0.0070%. The transmission electron microscope photos of the products are shown in image 3 ,Depend on image 3 It can be seen that the product is a nano hollow tube structure.

Embodiment 3

[0073] Add 10 parts of manganese powder to 150 parts of ethanol at 80-85°C, add 10 parts of ammonium acetate catalyst, add 60 parts of distilled water and stir for 10 hours, adjust the pH to 7-9, and stir with air for 2-6 hours; centrifuge, wash, The product is obtained after drying and grinding. The yield of trimanganese tetraoxide obtained was 99%.

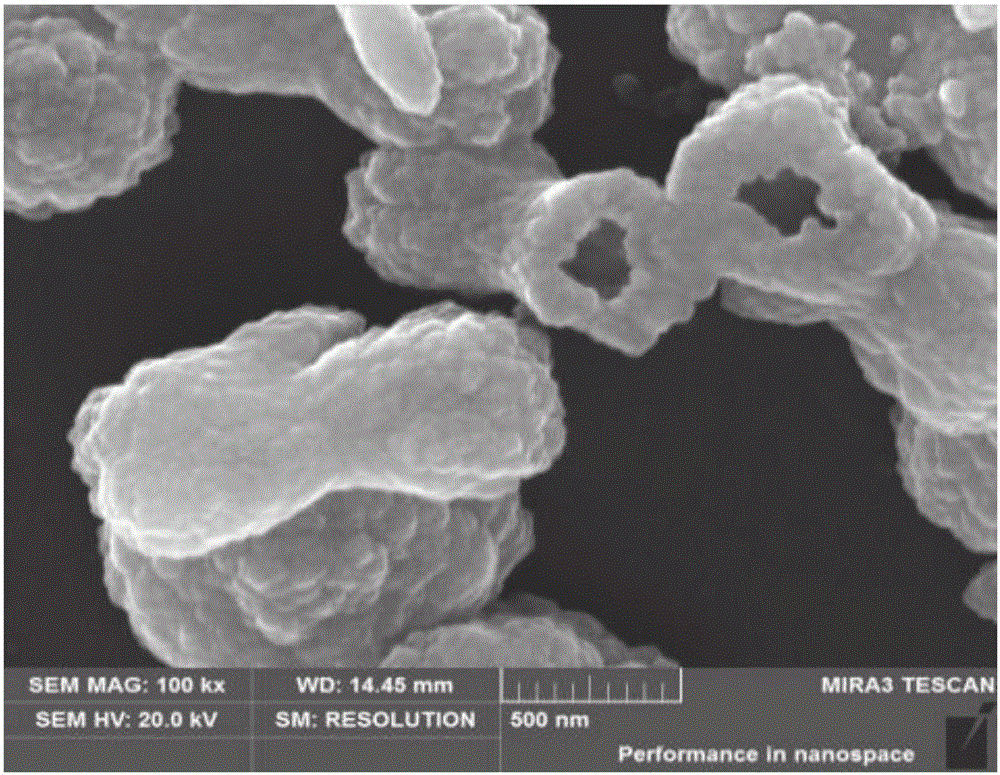

[0074] The product has been tested and the specific surface area of the manganese tetraoxide product is 72.8m 2 / g, Mn element content 70.80%, CaO content 0.0015%, K content 0.0005%, Na content 0.0025%, S content 0.0080%. Scanning electron microscope and transmission electron microscope photos see Figure 4 ,Depend on Figure 4 (a), (b) it can be seen that the product is a folded nanosheet, by Figure 4 (c) and (d), it can be seen that the product is composed of crystal grains of 10-15nm. XRD spectrum and Mn of trimanganese tetraoxide 3 o 4 The standard diffraction pattern of Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com