Method for preparing polyethylene-polyamine-modified biomass-based magnetic heavy metal adsorbent

A polyethylene polyamine, biomass technology, applied in the directions of alkali metal compounds, chemical instruments and methods, adsorbed water/sewage treatment, etc., to achieve the effect of reducing use costs, reducing pollution, and converting organic resources with high efficiency and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

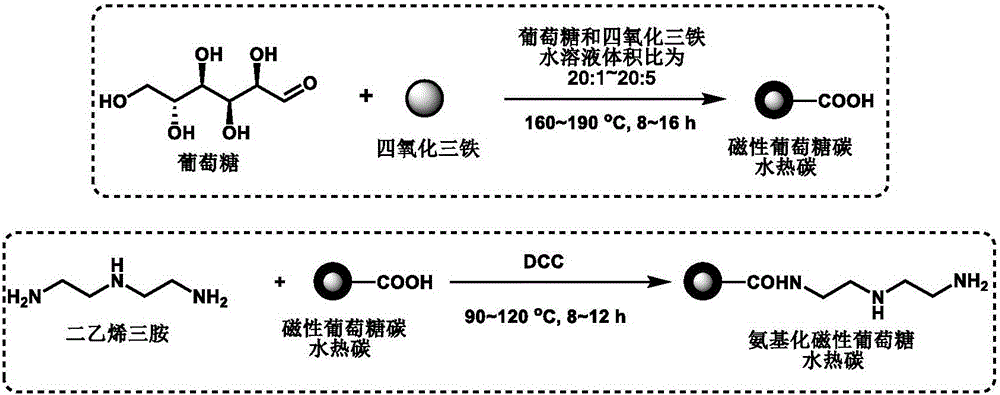

[0032] This embodiment relates to a method for modifying magnetic glucose hydrothermal carbon with diethylenetriamine as a monomer, comprising the following steps:

[0033]

[0034] The method comprises the steps of:

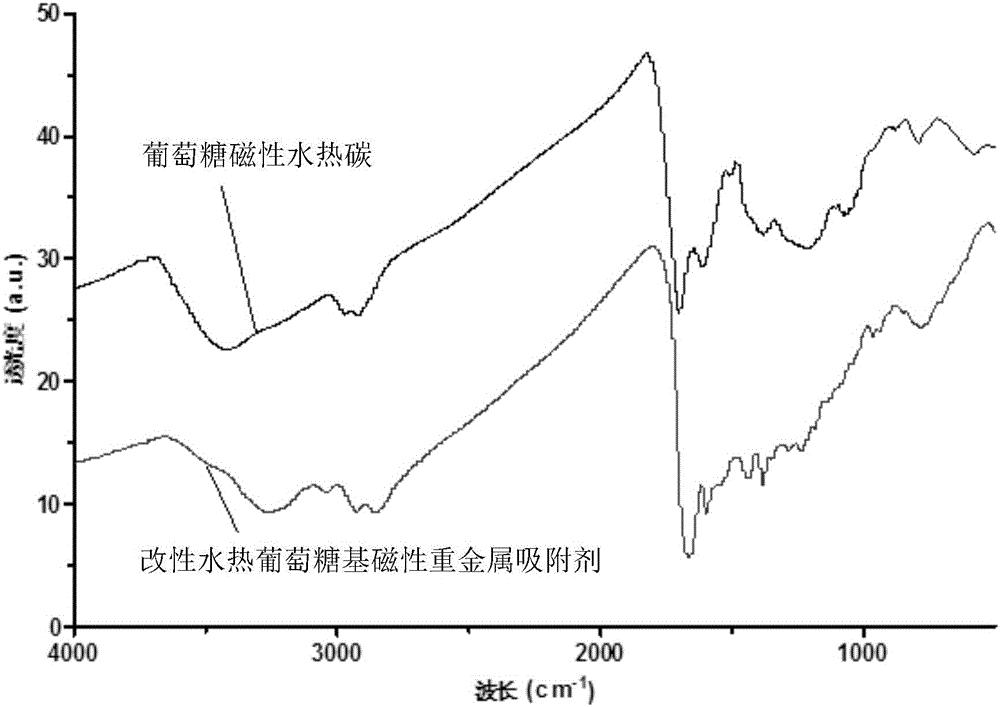

[0035] Dissolve glucose in water, stir for 10 minutes to form a clear glucose solution (20ml, glucose mass content is 10%), add 1ml of ultrasonic ferric oxide aqueous solution (25g / 100ml) to the glucose solution, and place it on the Teflon lining After mixing evenly in the high-pressure reactor and ultrasonication, seal the reactor and start the reaction. When the reaction temperature reaches 190°C, start to count the time and keep it at 190°C for 8 hours. After the reaction is completed, cool down at room temperature. The reaction mixture was filtered and the filtrate was collected, separated and purified to obtain magnetic glucose carbon hydrothermal carbon with a yield of 76.4%. FTIR analysis such as figure 1 shown. Mix 0.5g of glucose magnetic hydrothe...

Embodiment 2

[0041] This example relates to a method for modifying magnetic glucose hydrothermal carbon with triethylenetetramine as a monomer, and the reaction equation is as follows:

[0042]

[0043] Including the following steps:

[0044] Dissolve glucose in water, stir for 10 minutes to form a clear glucose solution (20ml, glucose mass content is 10%), add 3ml of ultrasonic ferric oxide aqueous solution (25g / 100ml) to the glucose solution, and place it on the Teflon lining After mixing evenly in the high-pressure reactor and ultrasonicating, seal the reactor and start the reaction. When the reaction temperature reaches 160°C, start to count the time and keep it at 160°C for 16 hours. The reaction mixture was filtered and the filtrate was collected, separated and purified to obtain magnetic glucose carbon hydrothermal carbon with a yield of 71.3%. Mix 0.5g of glucose magnetic hydrothermal carbon, 0.25g of DCC, and 10ml of triethylenetetramine, stir evenly, heat in an oil bath at 10...

Embodiment 3

[0050] This embodiment relates to a method for modifying magnetic glucose hydrothermal carbon with tetraethylenepentamine as a monomer, and the reaction equation is as follows:

[0051]

[0052] The method comprises the steps of:

[0053] Dissolve glucose in water, stir for 10 minutes to form a clear glucose solution (20ml, glucose mass content is 10%), add 5ml of ultrasonic ferric oxide aqueous solution (25g / 100ml) to the glucose solution, and place it on the Teflon lining After mixing evenly in the high-pressure reactor and ultrasonicating, seal the reactor and start the reaction. When the reaction temperature reaches 190°C, start to count the time and keep the temperature at 190°C for 4 hours. After the reaction is completed, cool down at room temperature. The reaction mixture was filtered and the filtrate was collected, separated and purified to obtain magnetic glucose carbon hydrothermal carbon with a yield of 77.6%. Mix 0.5g of glucose magnetic hydrothermal carbon, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com