Black tea beverage making method

A production method and beverage technology, applied in tea, tea extraction, food science, etc., can solve the problems of large differences in the degree of secondary fermentation and the inability to ensure the consistency of black tea beverage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of black tea beverage, comprises the following steps:

[0028] The first step is to obtain tea soup: soak the dry black tea in the soaking liquid at 20°C, the soaking liquid is pure water, the mass ratio of dry black tea to pure water is 1:10-1:15, and then the tea is soaked every 5 minutes Heating the pure water at a rate of 1°C at a constant speed, when the temperature of the pure water reaches 90°C, stop heating, and then filter out the tea dregs to obtain tea soup;

[0029] The second step, fermentation: use the refrigerant obtained in the first step to quickly cool down the device containing the tea soup, so that the temperature of the tea soup will drop to 25°C-30°C within 2 minutes; then pour the tea soup into the fermentation tank, take fresh red Tea leaves, and grind them into tea paddles, pour the tea paddles into the fermentation tank, the volume ratio of the tea paddles to the tea soup is 1:15, then feed oxygen at 25°C into the f...

Embodiment 2

[0042]The difference between the present embodiment and the first embodiment is: fermentation: the pressure of oxygen is 1Mpa, and the stirring is canceled; the sterilization and packaging step, after the finished beverage is packaged, the finished beverage is cooled at 0°C for 10 minutes. In addition, the parameters from the first step to the sixth step have been adjusted accordingly, see Table 1. The black tea beverage made by this scheme has a longer shelf life.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is: the third step, extracting the fermented liquid: put dry ice into the fermenter fermented in the second step, then forwardly rotate the fermenter at 50r / min for 10min, reverse for 10min, Then stand still for 30min; then extract the fermentation broth in the fermenter under the environment full of nitrogen. Step 6: Sterilization and packaging. After the finished beverage is frozen into beverage ice cubes, it is packaged. In addition, adjust the corresponding parameters from the first step to the sixth step, see Table 1 for details. The black tea beverage that is made by the method for this program has purer mouthfeel.

[0045]

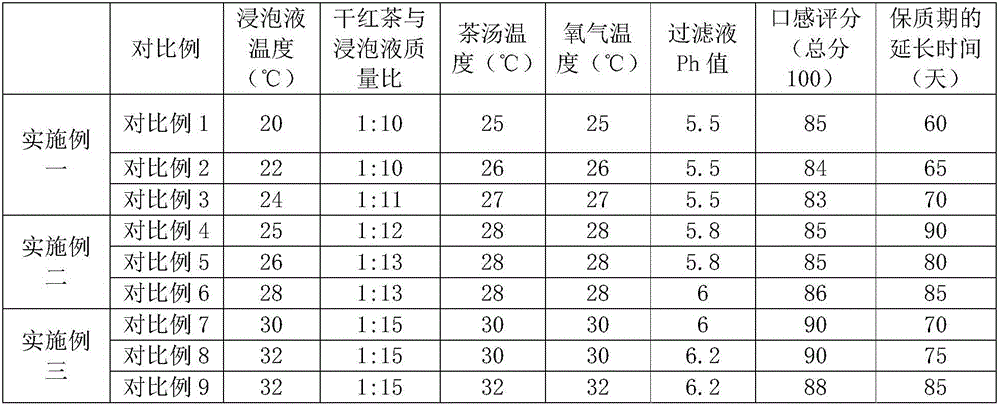

[0046] Table I

[0047] In the above table, the extension of the shelf life refers to: compared with the traditional production process, the shelf life of the black tea beverage is extended on the original basis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com