Grain rapid dryer

A rapid drying and dryer technology, applied in the direction of drying and preserving seeds, etc., can solve the problem of grain storage being susceptible to moisture and other problems, and achieve the effects of rapid work, flexible movement of positions, and convenient storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

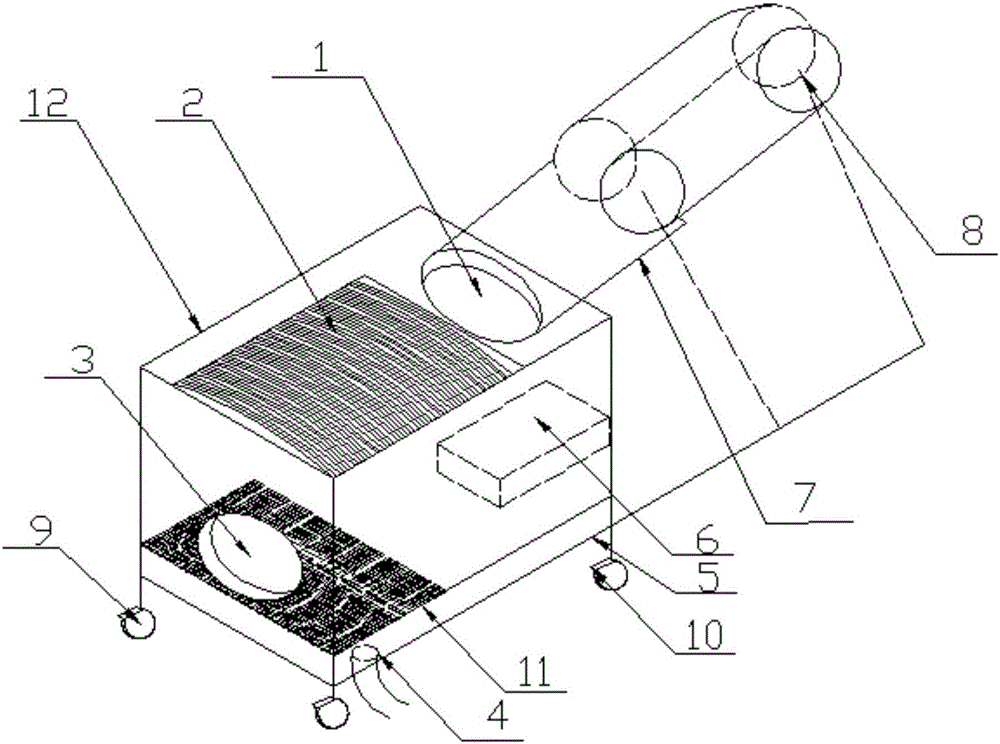

[0014] Such as figure 1 As shown, the present invention provides a quick dryer for grain, comprising a feed port 1, a hot air dryer 2, a discharge port 3, a drain port 4, a condensation box 5, a humidity detector 6, a chute 7, and a conveyor belt 8. Steering wheel 9, brake 10, dehumidifier 11 and dryer body 12, the top side of the dryer body 12 is provided with a feed inlet 1, the top of the dryer body 12 is equipped with a hot air dryer 2, and the feed inlet The chute 7 is installed on one side, the condensation box 5 is installed at the bottom of the dryer body 12, the dehumidifier 11 is installed on the top of the condensation box 5, the drain port 4 is installed at the bottom of the condensation box 5, and the humidity detector 6 is installed inside the dryer body 12 . The hot air dryer evaporates the water in the grain and blows it to the bottom of the device, and the water vapor can be quickly discharged into the condensation box through the dehumidifier. The humidity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com