Automatic fly maggot separation machine

An automatic separation and separator technology, applied in animal husbandry and other directions, can solve the problems of high labor intensity, low separation rate, water pollution, etc., and achieve the effect of promoting separation effect, reducing production cost and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

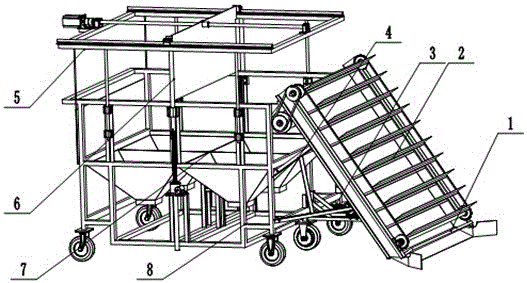

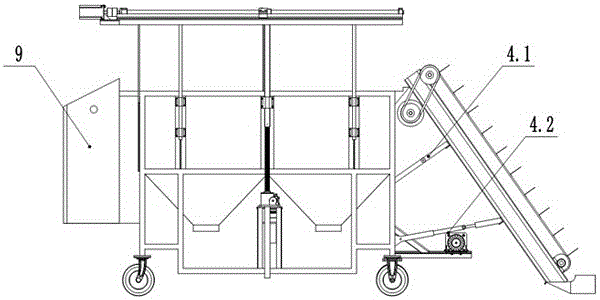

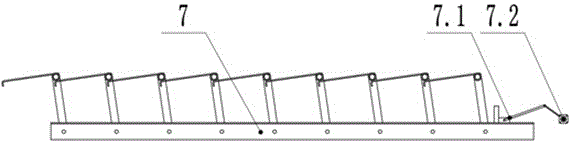

[0016] Such as figure 1 As shown, the fly maggot automatic separator of the present invention is mainly composed of a machine vision detection system 1, a reverse scraper conveying system 2, a walking system 3, a conveyor belt obstacle-crossing assembly 4, a separation system 5, a lifting assembly 6, and a louver Vibration device 7, ultrasonic obstacle avoidance module 8, PLC control system 9 and other components. Among them, the reverse scraper conveying system 2 is installed at the front end of the separator, and the mounting support is composed of a movable hinge 4.1 and two linked electric push rods 4.2; the machine vision detection system 1 is installed on the front support frame of the conveying system; The barrier assembly 4 is installed between the conveying system and the main body of the separator. When the machine vision detection system detects an obstacle high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com