Intelligent scanning online measurement system and intelligent scanning online measurement method based on image identification

An image recognition and measurement system technology, applied in the field of intelligent scanning online measurement system, can solve the problems of restricting the application of robots, low detection efficiency, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The invention will be described in further detail below in conjunction with the accompanying drawings.

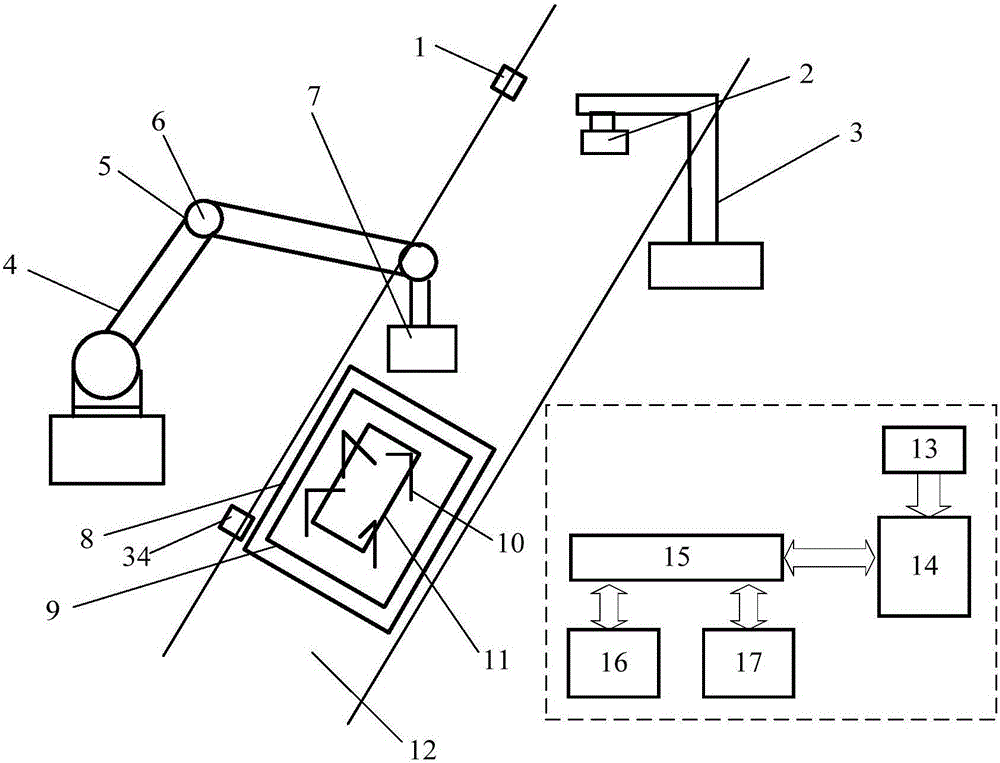

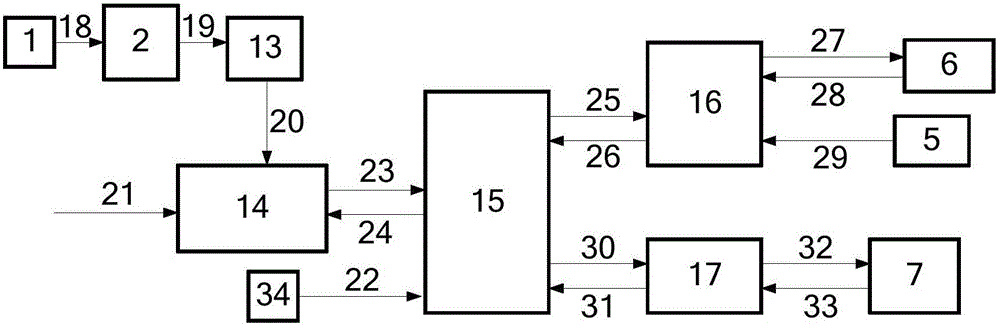

[0056] Such as figure 1 As shown, the intelligent scanning online measurement system based on image recognition of the present invention includes an image recognition positioning module, a six-degree-of-freedom robot laser scanning measurement module, a measurement control module, and also includes a welding production line 12, located in the welding production line 12 Accompanying platform 8 on the platform, accompanying fixture tray 9 on accompanying platform 8, fixture 10 on the accompanying fixture tray 9, and parts 11 on the fixture 10, wherein the image recognition positioning module is triggered by the CCD camera switch 1, CCD camera 2, The CCD camera bracket 3 and the CCD camera electronic control unit (ECU) 13 are composed. The CCD camera trigger switch 1 is located on the production line, and the CCD camera bracket 3 located next to the production line supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com