Micro heat pipe and manufacturing method of micro heat pipe

A technology of micro heat pipes and manufacturing methods, which can be applied to indirect heat exchangers, lighting and heating equipment, etc., and can solve problems such as post-processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0054] By performing the above steps, a micro heat pipe 10 can be manufactured. The use of the micro heat pipe 10 and the achievable effects have been described in the first embodiment, and will not be repeated here.

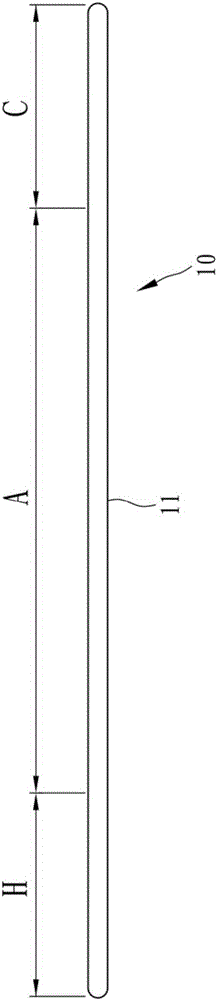

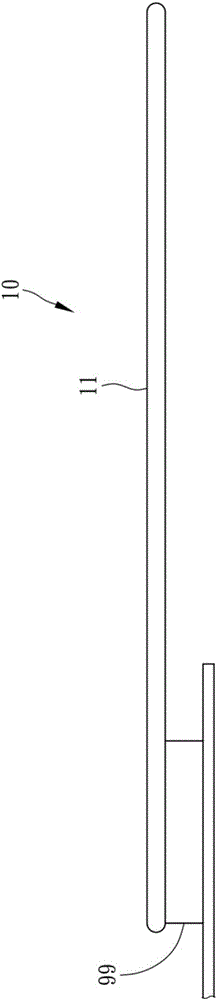

[0055] Such as Figure 17 As shown, the second embodiment may further include a marking step: a mark 19 is provided on the surface of the tube 11 so that the position of the heated section H can be identified. Thereby, the user can judge the position of the heated section H of the micro heat pipe 10 from the appearance of the micro heat pipe 10. The setting method of the mark 19 has been described in the first embodiment, and will not be repeated here.

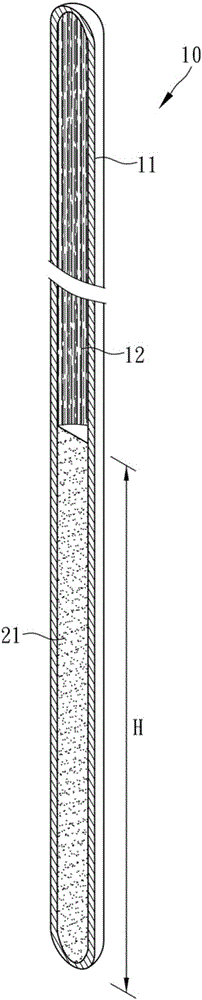

[0056] In the second embodiment, in the foregoing preparation step, the prepared tube 11 may also be a grooved tube, that is, the inner tube wall of the tube 11 is provided with a plurality of grooves extending in the axial direction. The grooves 14, thereby, in the foregoing etching step, the first capillary struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com