Control method for demonstration and representation of automatic cutting of drum shearer

A technology of a shearer and a drum, which is applied in the field of automatic cutting control of teaching and reproduction of drum shearers, can solve the problems of poor sight line of coal mining face, poor coal loading effect, poor use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

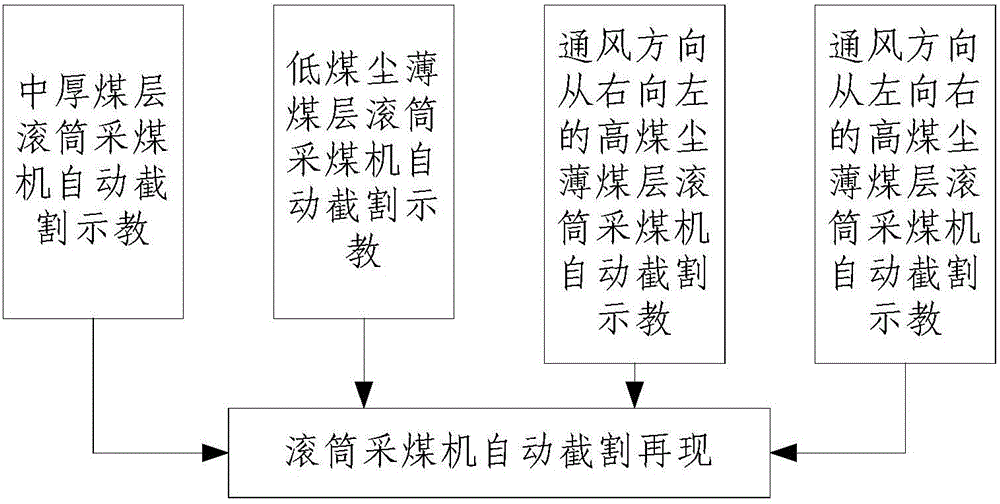

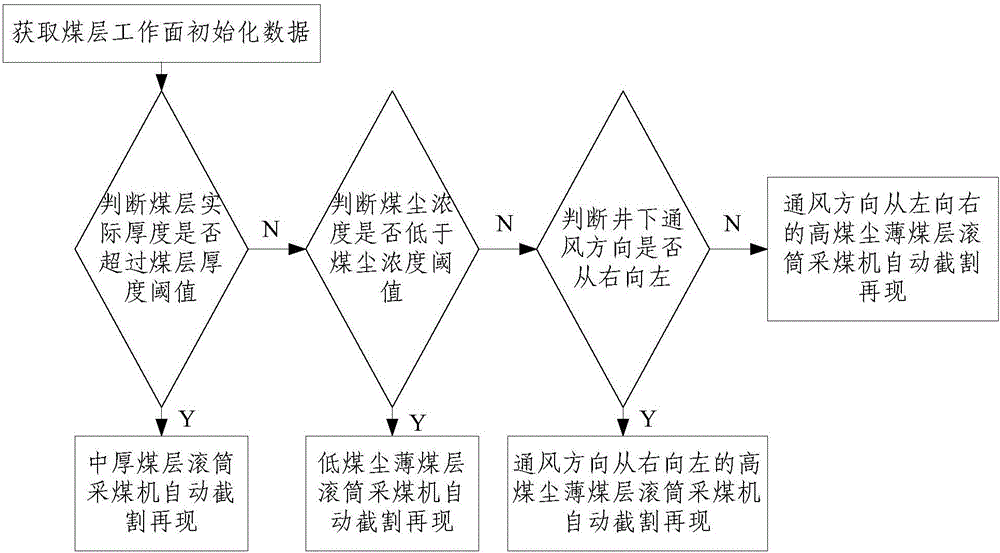

[0146] like Figure 1 to Figure 7 As shown, the teaching reproduction automatic cutting control method of the coal mining machine of the present invention includes the following steps:

[0147] Step 1. Automatic cutting and teaching of the medium-thick coal seam drum shearer: along the length direction of the medium-thick coal seam mining area, use the drum shearer control system to control the drum shearer from front to back to the medium-thick coal seam to be mined. Layer-by-layer mining; in the layer-by-layer mining process, the mining methods for the two coal seams that are connected to each other at the working face of the medium-thick coal seam to be mined are the same;

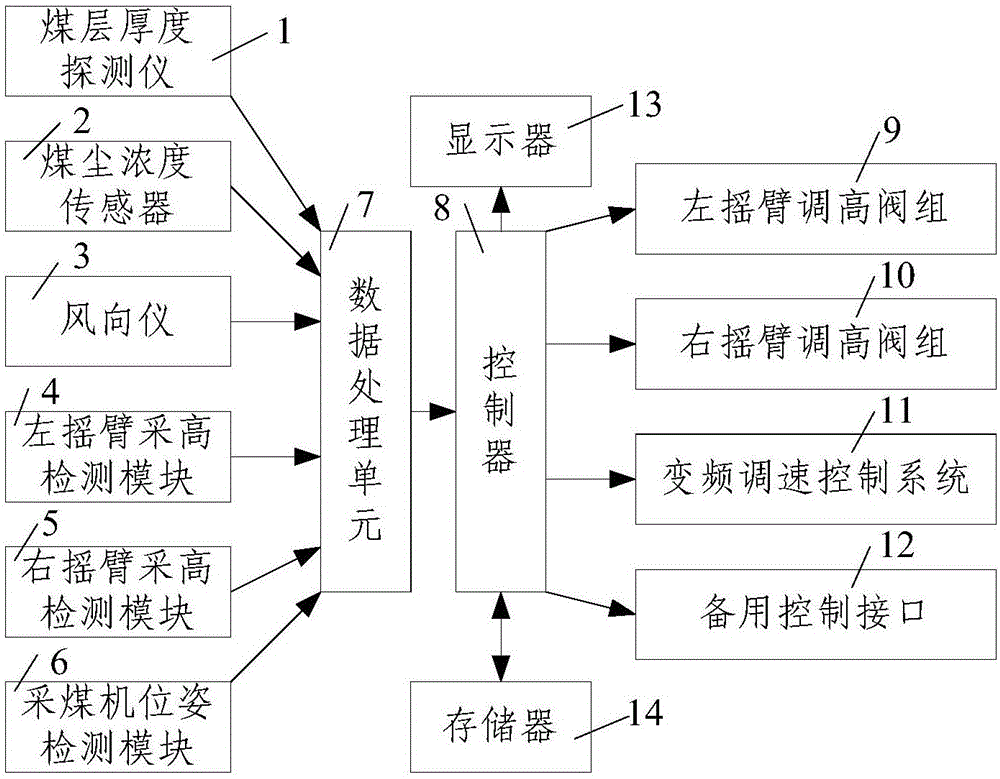

[0148] The drum shearer control system includes a controller 8 and a memory 14 connected to the controller 8, the input of the controller 8 is connected with a data processing unit 7, and the input of the data processing unit 7 is connected with a coal seam thickness detector 1 , coal dust concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com