Masonry-wall line-pipe, line-groove and line-box burying construction method

A construction method and a technology of pipeline troughs, which are applied in the processing of building materials, construction, and installation of cables, etc., can solve problems such as easy cracking of the wall and environmental pollution, and achieve the goals of eliminating cracks in the wall, shortening the construction period, and ensuring quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

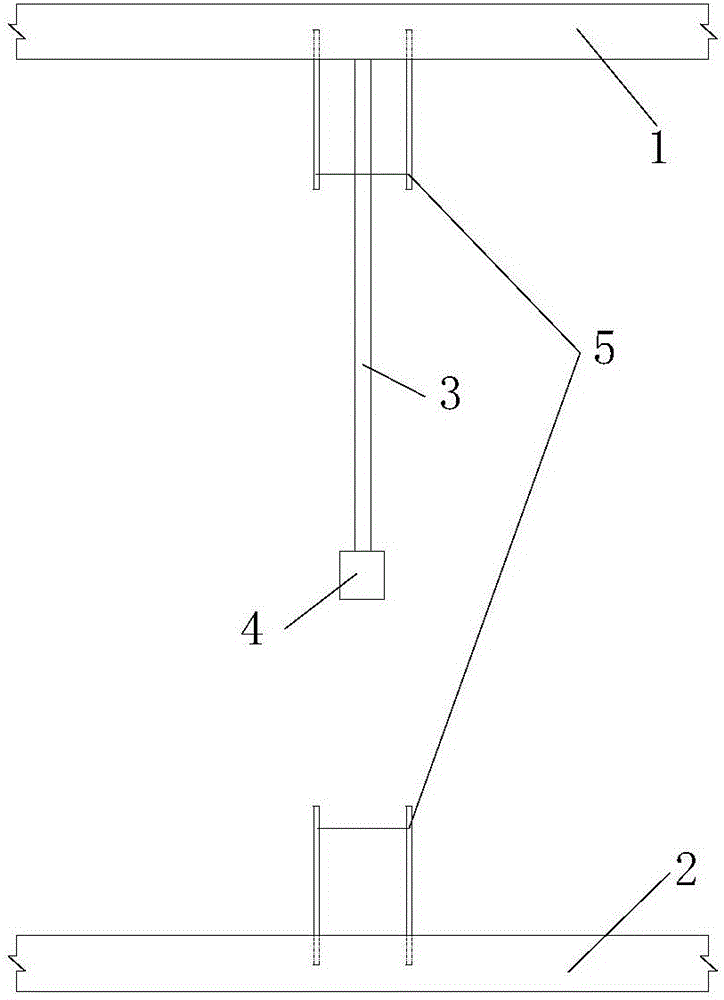

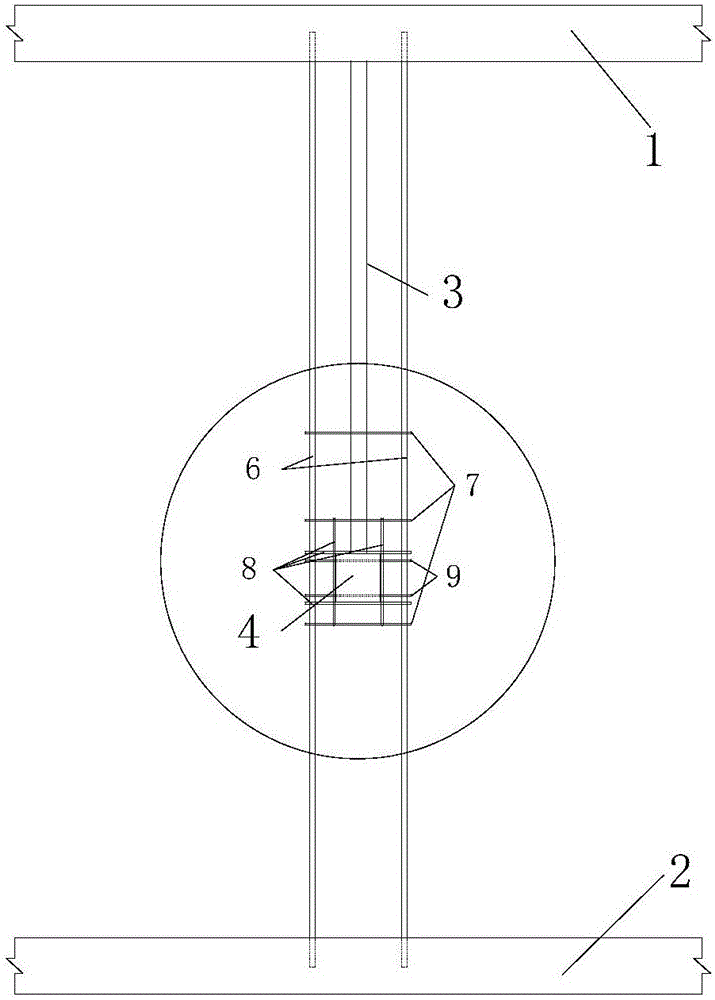

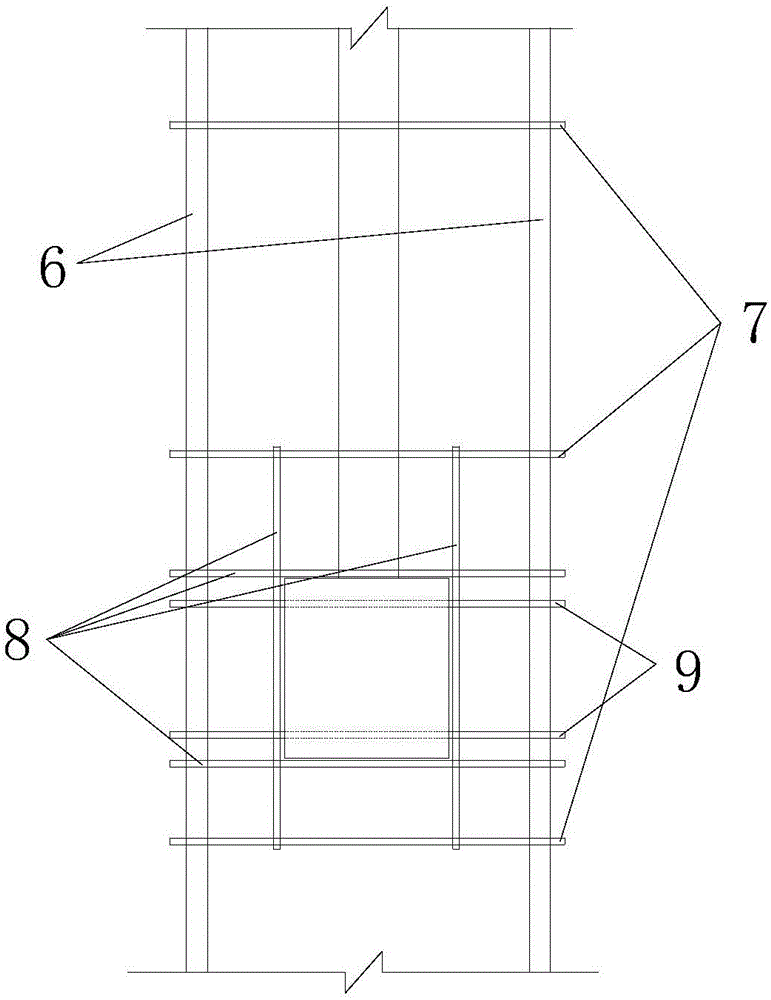

[0041] refer to Figure 1 to Figure 4 As shown, a kind of construction method of concealed burying of line, pipeline, trough and line box of masonry wall body described in Embodiment 1 of the present invention, the construction before wall body masonry is the construction of method first, and the method of first method construction specifically comprises the following steps:

[0042] (1) Embed pre-embedded steel bars 5 in the bottom plate 2 and roof 1 (or floor beams) around the line groove of the buried line pipe 3 in the masonry wall, or in the construction of the main structure. The pre-embedded reinforcement 5 adopts about A12mm concrete structural column reinforcement, the thickness of the concrete structural column reinforcement is the same as that of the wall 10, the implantation depth is about 200mm, and the exposed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com