Building deformation joint concrete double-wall synchronous pouring construction method

A construction method and synchronous pouring technology, which is applied to buildings, building components, building structures, etc., can solve problems affecting project progress, resource consumption, poor formwork support, etc., to achieve environmental protection, save formwork, and save materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

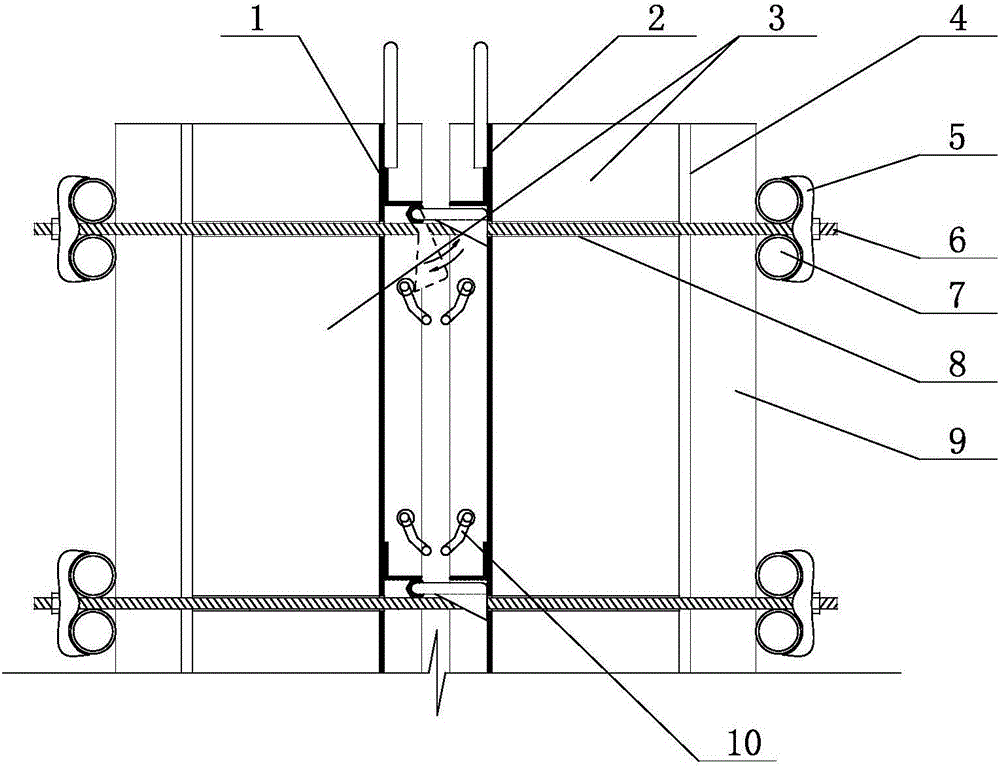

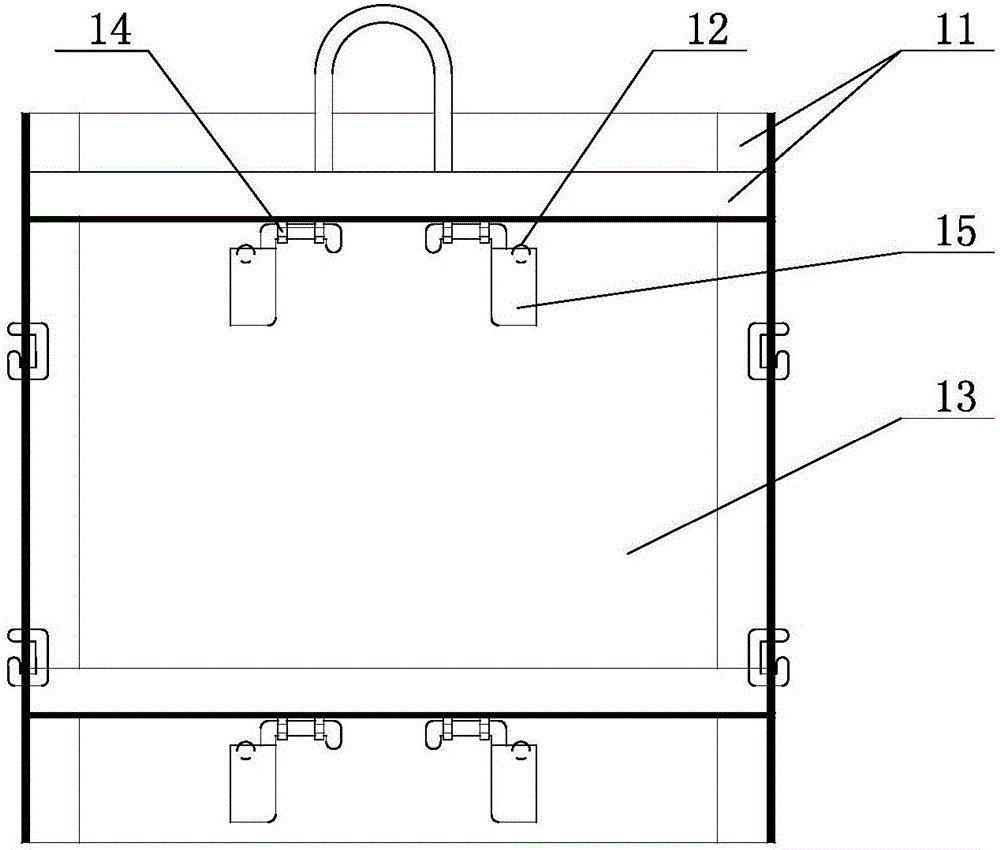

[0033] Such as Figure 1 to Figure 5 Shown, the building deformation joint concrete double wall synchronous pouring construction method of the present invention, take the following steps:

[0034] 1) Make the deformation joint main steel mold 1, the deformation joint auxiliary steel mold 2, the deformation joint main steel mold 1 and the deformation joint auxiliary steel mold 2 both include the steel plate 13 and the angle steel 11 located on the steel plate 13, and the deformation joint main steel mold 1 A supporting positioning device 15 is provided at the bottom of the back flute of the angle steel, and the main steel mold 1 of the deformation joint and the auxiliary steel mold 2 of the deformation joint are spliced to the required length by clamping the return pin 10 with the angle steel; the single piece width of this device is 600mm.

[0035] 2) Use lifting equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com