Method for designing mix proportion of bituminous mixture for ultra-thin wearing course

A technology of asphalt mixture and mix ratio design, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve problems such as shear index, looseness, and peeling of asphalt mixture that are not involved, and prevent early damage to the road surface , Excellent high temperature performance, good shear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

[0039] The invention provides a method for designing the mixing ratio of an ultra-thin wearing layer asphalt mixture, which comprises the following steps:

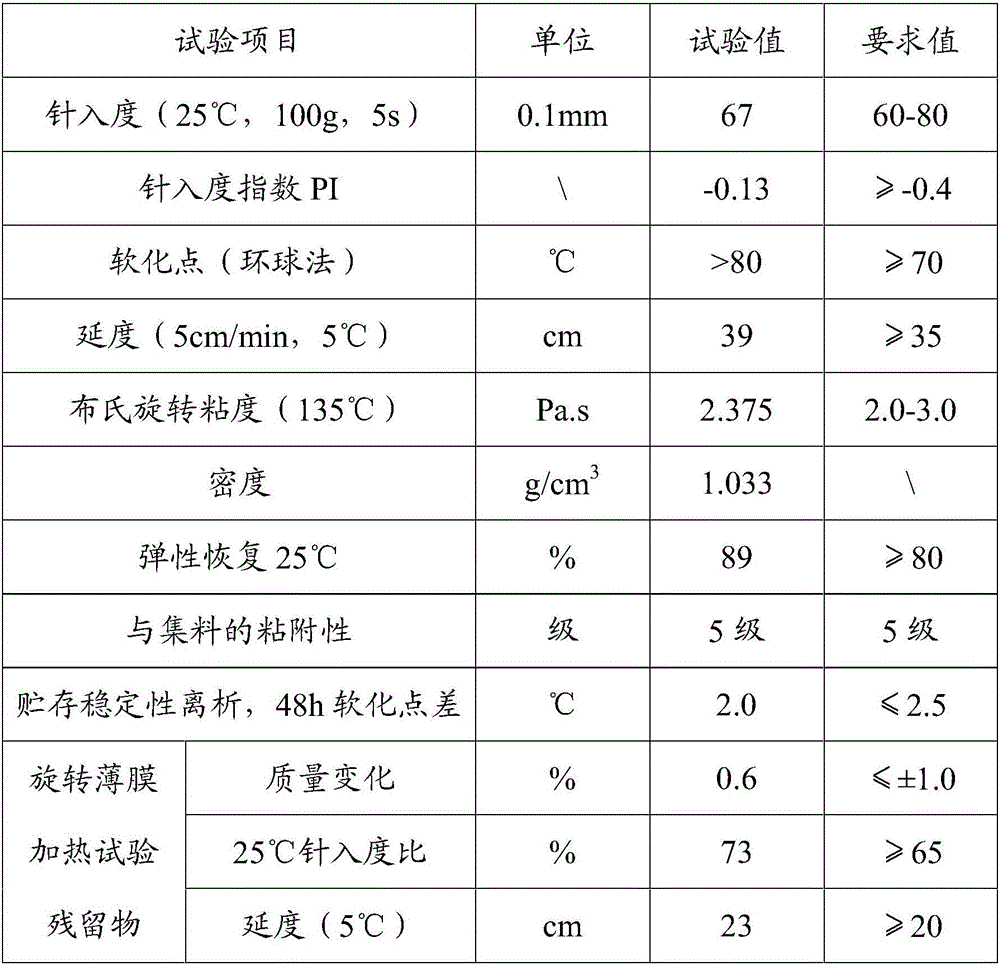

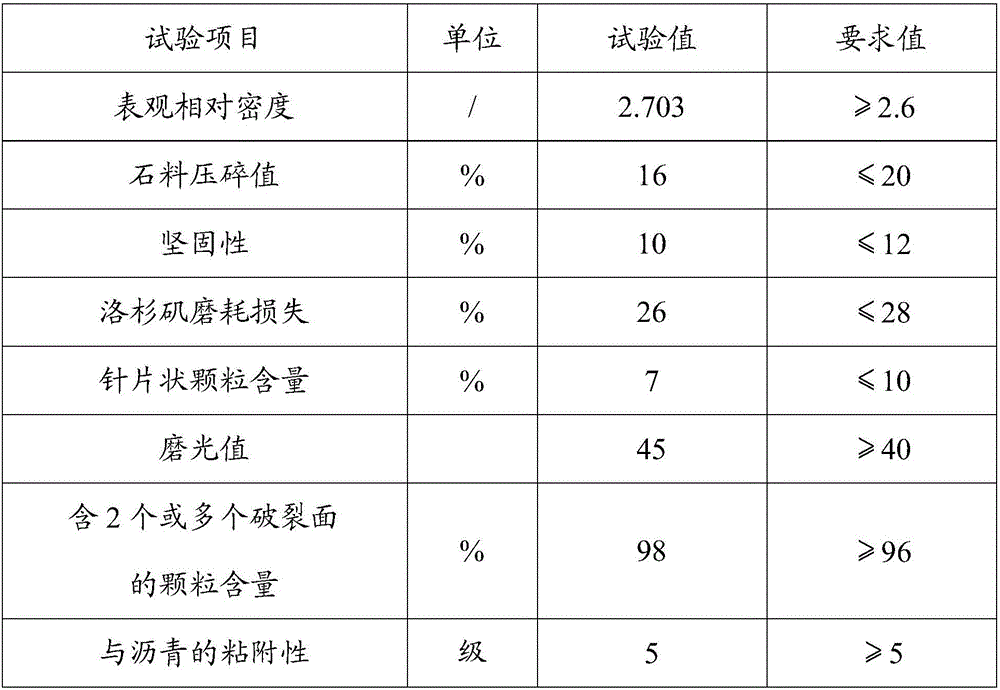

[0040] Step 1, select the raw material of the asphalt mixture for the ultra-thin wear layer, the raw material includes asphalt and mineral aggregate;

[0041] Step 2, design the mix ratio of the ultra-thin wearing layer asphalt mixture;

[0042] Step 2a, designing the gradation of the asphalt mixture in the ultra-thin wearing layer;

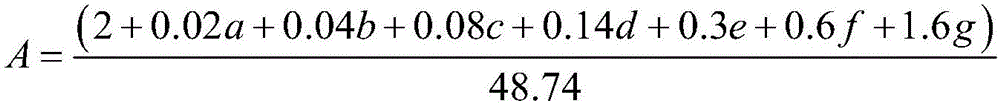

[0043] Step 2b, determine the optimum asphalt ratio of ultra-thin wearing layer asphalt mixture;

[0044] Step 3, prepare the ultra-thin wearing layer asphalt mixture according to the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extensibility | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com