Method for increasing discharging uniformity of aluminum oxide of aluminum cell

An aluminum electrolytic cell and alumina technology, which is applied in the field of improvement of the feeding method of pre-baked aluminum electrolytic cells, can solve problems such as blocking of the electrolytic cell, and achieve the effects of reducing the feeding amount, improving the uniform distribution, and reducing the potential energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

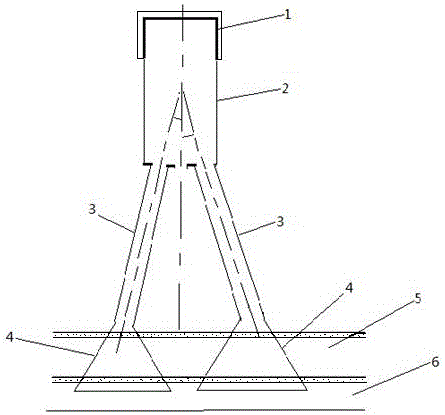

[0029] According to the upper structure of a 200kA experimental electrolytic cell, a new alumina feeding channel is designed.

[0030] The original design of the 200kA electrolyzer has 4 feeding ports, and there is a feeding container above each feeding port. From the aluminum outlet end to the flue end, it is recorded as the 1st, 2nd, 3rd, and 4th blanking container. After removing the shelling hammer of the electrolytic cell, design and install a material guide tube with an inner diameter of 100mm and a length of 300mm on each blanking container.

[0031] The lower ends of the 1st and 4th feeding pipes are respectively provided with 3 branch feeding pipes, wherein the centerline of one branch feeding pipe and the centerline of the feeding pipe are at an angle of 0° and overlap, and its diameter is 20mm. The other two branch feeding pipes are symmetrically distributed on both sides of the feed pipe along the middle seam of the electrolytic cell, the angle between the center ...

Embodiment 2

[0035] According to the upper structure of a 200kA experimental electrolytic cell, a new alumina feeding channel is designed.

[0036] The original design of the 200kA electrolyzer has 4 feeding ports, and there is a feeding container above each feeding port. From the aluminum outlet end to the flue end, it is recorded as the 1st, 2nd, 3rd, and 4th blanking container. After removing the shelling hammer of the electrolytic cell, design and install a material guide tube with an inner diameter of 100mm and a length of 500mm on each blanking container.

[0037] The lower ends of the 1st and 2nd feeding pipes are respectively provided with 3 branch feeding pipes, wherein the center line of one branch feeding pipe and the feeding pipe center line are at an angle of 0° and overlap, and its diameter is 18mm. The other two branch feeding pipes are symmetrically distributed on both sides of the branch feeding pipe along the middle seam of the electrolytic cell, the angle between the cent...

Embodiment 3

[0041] According to the upper structure of a 500kA experimental electrolytic cell, a new alumina feeding channel is designed.

[0042] The original design of the 500kA electrolyzer has 6 feeding ports, and there is a feeding container above each feeding port. From the aluminum outlet end to the flue end, it is recorded as the 1st, 2nd, 3rd, 4th, 5th, and 6th blanking container. After removing the shelling hammer of the electrolytic cell, design and install a material guide tube with an inner diameter of 120mm and a length of 800mm on each blanking container.

[0043] The lower end of the first feeding pipe is provided with 2 branch feeding pipes, wherein the centerline of one branch feeding pipe and the centerline of the feeding pipe have an included angle of 0° and overlap, and its diameter is 40mm. The feeding pipe of another branch is located on the side of the aluminum outlet end of the first branch, the angle between the center line and the center line of the guide pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com