Metal plate induction heating device capable of realizing closed-loop temperature control

An induction heating device and sheet metal technology, which is applied in the field of sheet metal heating, can solve the problems of complicated device structure and high application cost, and achieve the effect of effective temperature data and convenient pick-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The specific structure of the present invention and its implementation will be further described below through examples and with reference to the accompanying drawings.

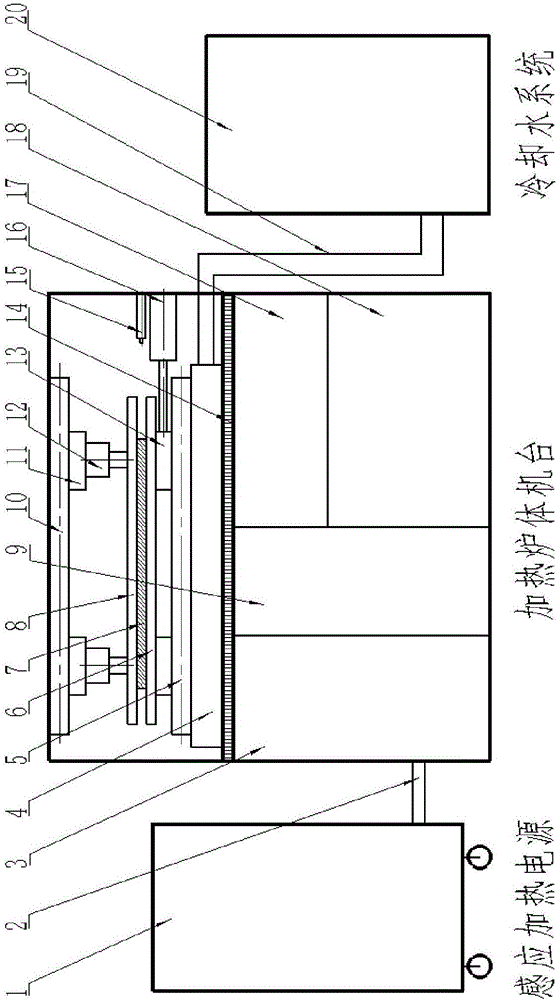

[0022] Such as figure 1 As shown, a metal sheet induction heating device capable of realizing temperature closed-loop control according to the present invention is composed of three parts: an induction heating power supply 1, a heating furnace body machine and a cooling water system, wherein the heating furnace body machine is heated by the upper part area and the lower storage area, and separated by the middle partition 14; the upper heating area of the heating furnace machine includes: workpiece clamping parts, servo motor 16, upper guide rail 10, lower guide rail 5, upper slider 11, Lower slider 13, flat panel sensor 4, infrared probe 15, wherein the workpiece clamping part is made up of workpiece upper splint 8, workpiece lower splint 6 and compression cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com