Lubricating oil detergent dispersant and preparation method thereof

A technology for cleaning and dispersing agents and lubricating oils, which is applied in the preparation of carboxylate salts, lubricating compositions, additives, etc., can solve the problems of not providing acid neutralization ability, poor dispersibility, and increasing costs, and achieve excellent high-temperature detergency, The effect of excellent low-temperature sludge dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

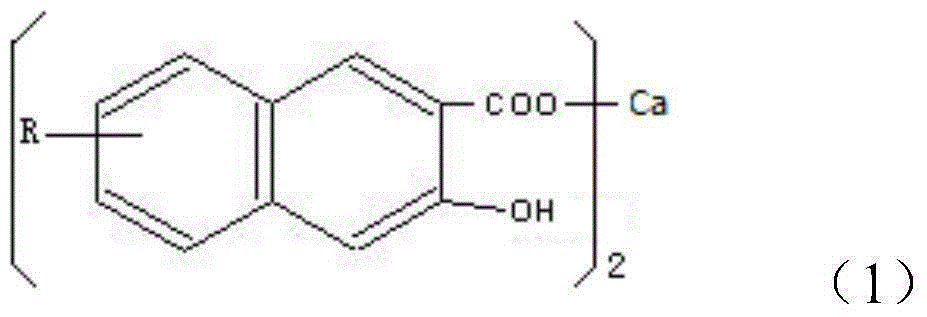

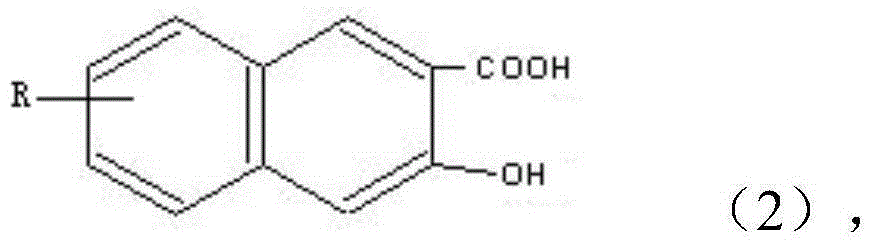

[0037] S1: In a 500mL airtight container equipped with a stirrer, thermometer, heating mantle and vent pipe, add 50.0g of solvent straight-run gasoline (C4-C12 alkane), 20.0g of accelerator methanol, and 6.0g of hydrogen peroxide Calcium, stir and heat up to 50°C;

[0038] S2: Continue to add 50.0 g of diluent vegetable oil, then add 100.0 g of tetradecyl 2-hydroxy-3-naphthoic acid, seal the reaction vessel, and carry out the neutralization reaction for 60 minutes;

[0039] S3: Introduce CO within 60 minutes after the neutralization reaction 2 2.0g of gas. After the reaction, the temperature was raised to 90°C and kept for 30 minutes, and the residue was removed by filtration. Finally, the solvent was evaporated to obtain the product.

[0040] The base value of the product is 54.6mgKOH / g, and the calcium content is 1.99%.

Embodiment 2

[0042] S1: In a 500mL airtight container equipped with a stirrer, a thermometer, a heating mantle and a vent pipe, add 175.0g of solvent n-octane, 110.0g of accelerator ethylene glycol, and 38.0g of calcium hydroxide in turn, and stir to heat up to 50°C;

[0043] S2: Continue to add 100.0 g of diluent base oil HVI 150, then add 100.0 g of tetradecyl 2-hydroxy-3-naphthoic acid, seal the reaction vessel, and carry out neutralization reaction for 60 minutes;

[0044] S3: Introduce CO within 120min after the neutralization reaction 2 Gas 21.0g. After the reaction, the temperature was raised to 90°C and kept for 30 minutes, and the residue was removed by filtration. Finally, the solvent was evaporated to obtain the product.

[0045] The base value of the product is 210mgKOH / g, and the calcium content is 7.7%.

Embodiment 3

[0047] S1: Add 300.0g of solvent cyclohexane, 200.0g of accelerator methanol, and 70.0g of calcium hydroxide in sequence in a 500mL airtight container equipped with a stirrer, thermometer, heating mantle and vent pipe, and stir to raise the temperature to 50°C ;

[0048] S2: Continue to add 100.0 g of eicosyl 2-hydroxy-3-naphthoic acid, seal the reaction vessel, and carry out the neutralization reaction for 60 minutes;

[0049] S3: Introduce CO within 180min after the neutralization reaction 2 40.0g of gas. After the reaction, the temperature was raised to 90°C and kept for 30 minutes, and the residue was removed by filtration. Finally, the solvent was evaporated to obtain the product.

[0050] The base value of the product is 301.1mgKOH / g, and the calcium content is 10.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com