A preparation method of multi-quantum dot core-silica shell composite structure and its application in LED

A technology of silica and composite structure, applied in chemical instruments and methods, nanotechnology for materials and surface science, semiconductor devices, etc., can solve problems such as quantum dot fluorescence efficiency decay, and achieve the effect of avoiding reabsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

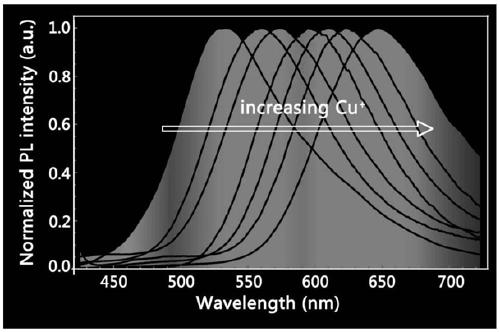

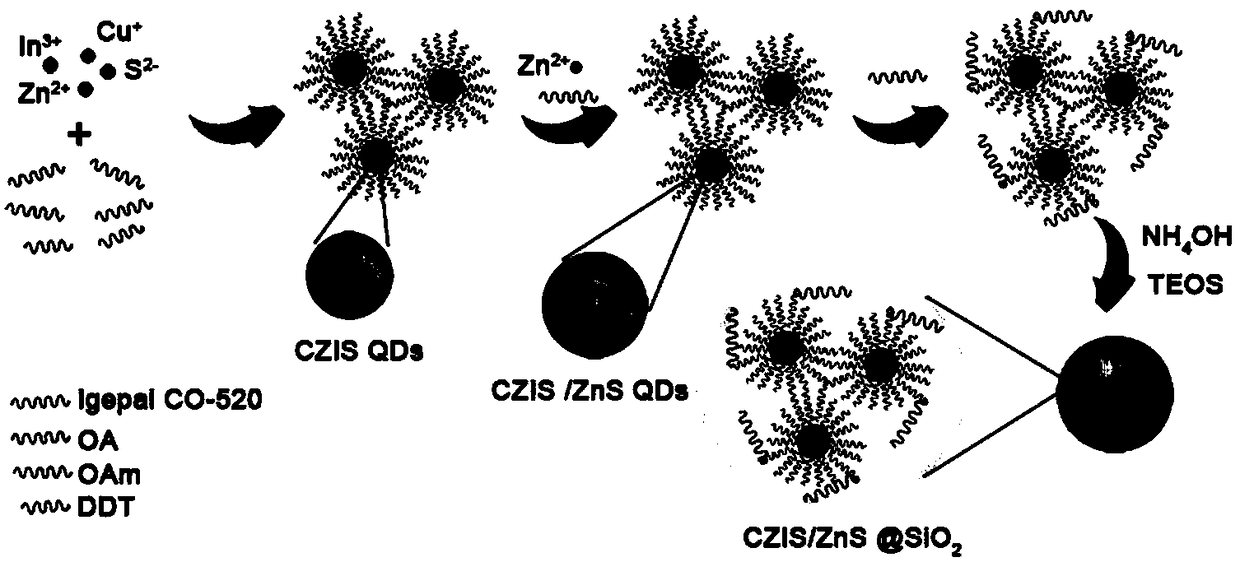

[0031] (1) Synthesis of oil-soluble CZIS / ZnS quantum dots:

[0032] 0.02mmol or 0.1mmol of CuCl, 0.4mmol of Zn(OAc) 2 , 0.4mmol of In(OAc) 3 , 3.2 mmol of S, 8 mL of DDT, 4 mL of OAm, and 2 mL of OA were added into a three-necked flask. After degassing at 100°C for 20 min, the mixture was heated to 230°C under nitrogen. After 10 min, the reaction was quenched. The reaction mixture was cooled to 80°C, and the OAm and ODE dissolved Zn(OAc) 2 Solution (the solution is 0.8mmol Zn(OAc) 2 OAm and ODE dissolved in 2 mL (the volume ratio of OAm and ODE is 1:9) were added to the above mixture, and the ZnS shell was grown on the CZIS core in situ. Then, the temperature of the system was raised to 240° C. for 20 minutes. The reaction was quenched by adding toluene.

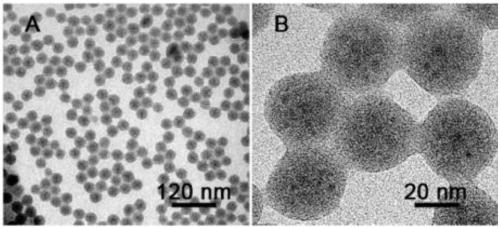

[0033] (2) Preparation of multi-quantum dot core-silica shell composite structure (CZIS / ZnS QDs@SiO 2 structure): the experiment encapsulated multiple CZIS / ZnS quantum dots into SiO by inverse microemulsion method 2...

Embodiment 2

[0036] (1) Synthesis of oil-soluble CZIS / ZnS quantum dots:

[0037] 0.02mmol or 0.1mmol of CuCl, 0.4mmol of Zn(OAc) 2 , 0.4mmol of In(OAc) 3 , 3.2 mmol of S, 8 mL of DDT, 4 mL of OAm, and 2 mL of OA were added into a three-necked flask. After degassing at 100°C for 20 min, the mixture was heated to 230°C under nitrogen. After 10 min, the reaction was quenched. The reaction mixture was cooled to 80°C, and the OAm and ODE dissolved Zn(OAc) 2 Solution (the solution is 0.8mmol Zn(OAc) 2 OAm and ODE dissolved in 2 mL (the volume ratio of OAm and ODE is 1:9) were added to the above mixture, and the ZnS shell was grown on the CZIS core in situ. Then, the temperature of the system was raised to 240° C. for 20 minutes. The reaction was quenched by adding toluene.

[0038] (2) Preparation of CZIS / ZnS QDs@SiO 2 The structure of the experiment: multiple CZIS / ZnS quantum dots were encapsulated into SiO by the method of inverse microemulsion 2 in the ball. 1 g of Igepal CO-520, 20...

Embodiment 3

[0041] (1) Synthesis of oil-soluble CZIS / ZnS quantum dots:

[0042] 0.02mmol or 0.1mmol of CuCl, 0.4mmol of Zn(OAc) 2 , 0.4mmol of In(OAc) 3 , 3.2 mmol of S, 8 mL of DDT, 4 mL of OAm, and 2 mL of OA were added into a three-necked flask. After degassing at 100°C for 20 min, the mixture was heated to 230°C under nitrogen. After 10 min, the reaction was quenched. The reaction mixture was cooled to 80°C, and the OAm and ODE dissolved Zn(OAc) 2 Solution (the solution is 0.8mmol Zn(OAc) 2 OAm and ODE dissolved in 2 mL (the volume ratio of OAm and ODE is 1:9) were added to the above mixture, and the ZnS shell was grown on the CZIS core in situ. Then, the temperature of the system was raised to 240° C. for 20 minutes. The reaction was quenched by adding toluene.

[0043] (2) Preparation of CZIS / ZnS QDs@SiO 2 The structure of the experiment: multiple CZIS / ZnS quantum dots were encapsulated into SiO by the method of inverse microemulsion 2 in the ball. 1 g of Igepal CO-520, 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com