Low-fluorescence anti-collapse blocking agent for drilling fluid and preparation method thereof

A low-fluorescence, plugging agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high fluorescence level, single function, poor compatibility, etc. The effect of protecting the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

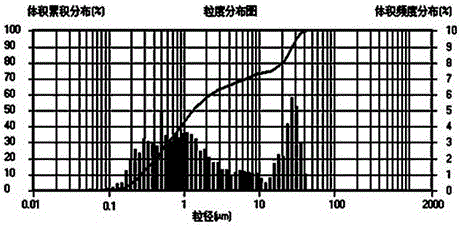

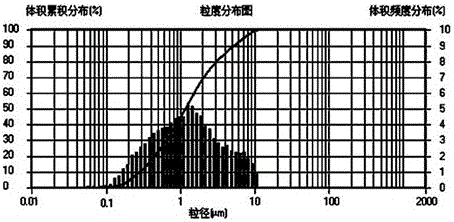

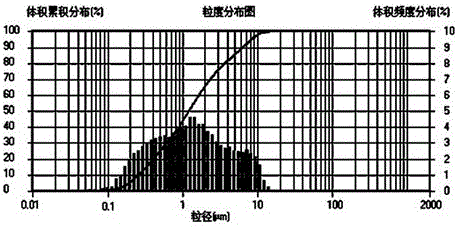

Image

Examples

Embodiment 1

[0028] Embodiment one: according to quality and 100% raw material preparation, food grade liquid paraffin 45%, fatty alcohol polyoxyethylene ether 8%, sodium alginate 0.5%, sodium dithionite 2%, polydimethylsiloxane 2%, remaining The amount is deionized water; add the prepared paraffin wax and surfactant in turn to the No. 1 reaction kettle, raise the temperature to 50°C, and stir for 60 minutes; add the prepared solvent, stabilizer and oxygen scavenger in turn to the No. 2 reaction kettle , antifoaming agent, heat up to 40°C, and stir for 30 minutes; slowly add the mixture obtained in No. 2 reactor to No. 1 reactor, and react at 40°C for 2 hours to obtain a paraffin microemulsion of a low-fluorescence anti-slump plugging agent.

Embodiment 2

[0029] Embodiment two: according to quality and 100% raw material preparation, cosmetic grade liquid paraffin 50%, lauryl alcohol polyoxyethylene ether sulfosuccinate disodium 6%, microcrystalline fiber 2%, carbohydrazide 0.5%, polyether modified Silicone 0.5%, the rest is distilled water; add the prepared paraffin wax and surfactant in turn to No. 1 reaction kettle, raise the temperature to 30°C, and stir for 50 minutes; , oxygen scavenger, defoamer, the temperature was raised to 50°C, and stirred for 40 minutes; the mixture obtained in No. 2 reactor was slowly added into No. 1 reactor, and reacted at 50°C for 3 hours to obtain TYRF-1.

Embodiment 3

[0030] Embodiment three: according to quality and 100% raw material preparation, medical grade liquid paraffin 60%, sorbitan oleate polyoxyethylene ether 4%, hydroxypropyl starch 1%, carbohydrazide 1%, polyoxyethylene polyoxyethylene 1% propanolamine ether, the balance is distilled water; add the prepared paraffin wax and surfactant in turn to No. 1 reaction kettle, raise the temperature to 40°C, and stir for 55 minutes; Stabilizer, oxygen scavenger, defoamer, heated to 45°C, and stirred for 40 minutes; slowly added the mixture obtained in No. 2 reactor to No. 1 reactor, and reacted at 40°C for 2 hours to obtain TYRF-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com