Blocking and anti-collapse agent used for drilling fluid and preparation method thereof

A technology of plugging and anti-slumping, drilling fluid, applied in the direction of chemical instruments and methods, chemical processing of tar asphalt/petroleum asphalt/natural asphalt, drilling composition, etc., can solve the problem of high fluorescence intensity of plugging and anti-slumping agents problems, to achieve the effect of accelerating the exploration and development process, good compatibility, and improving lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

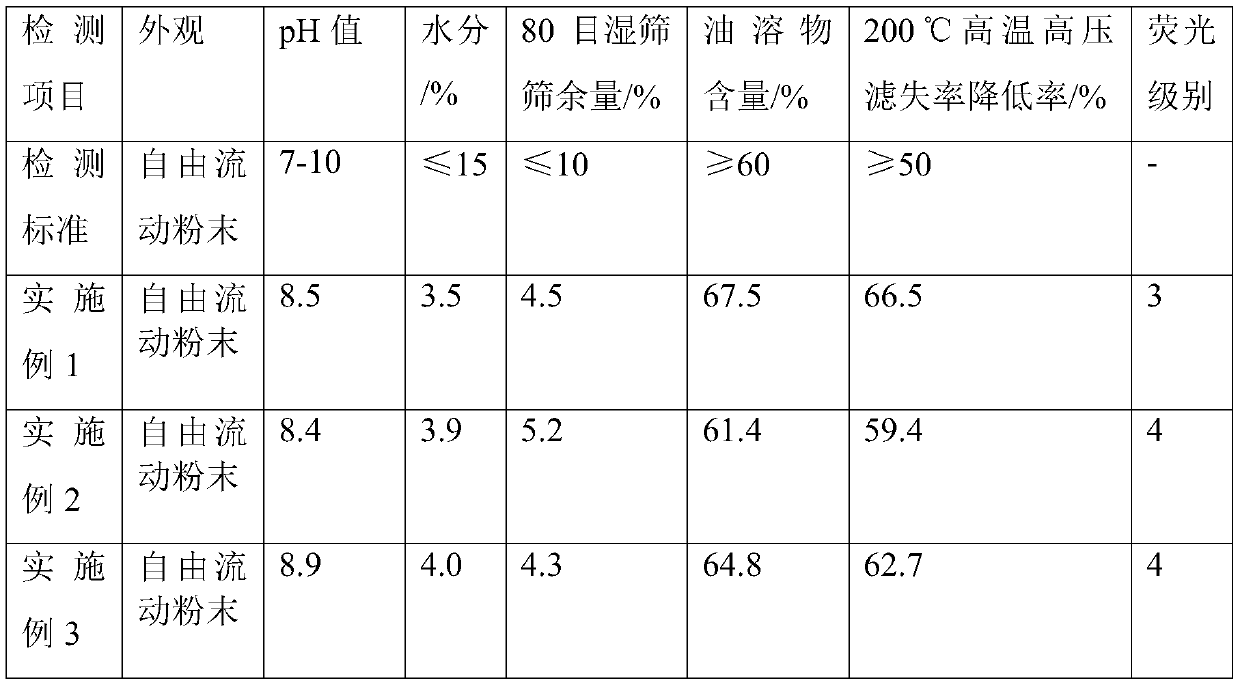

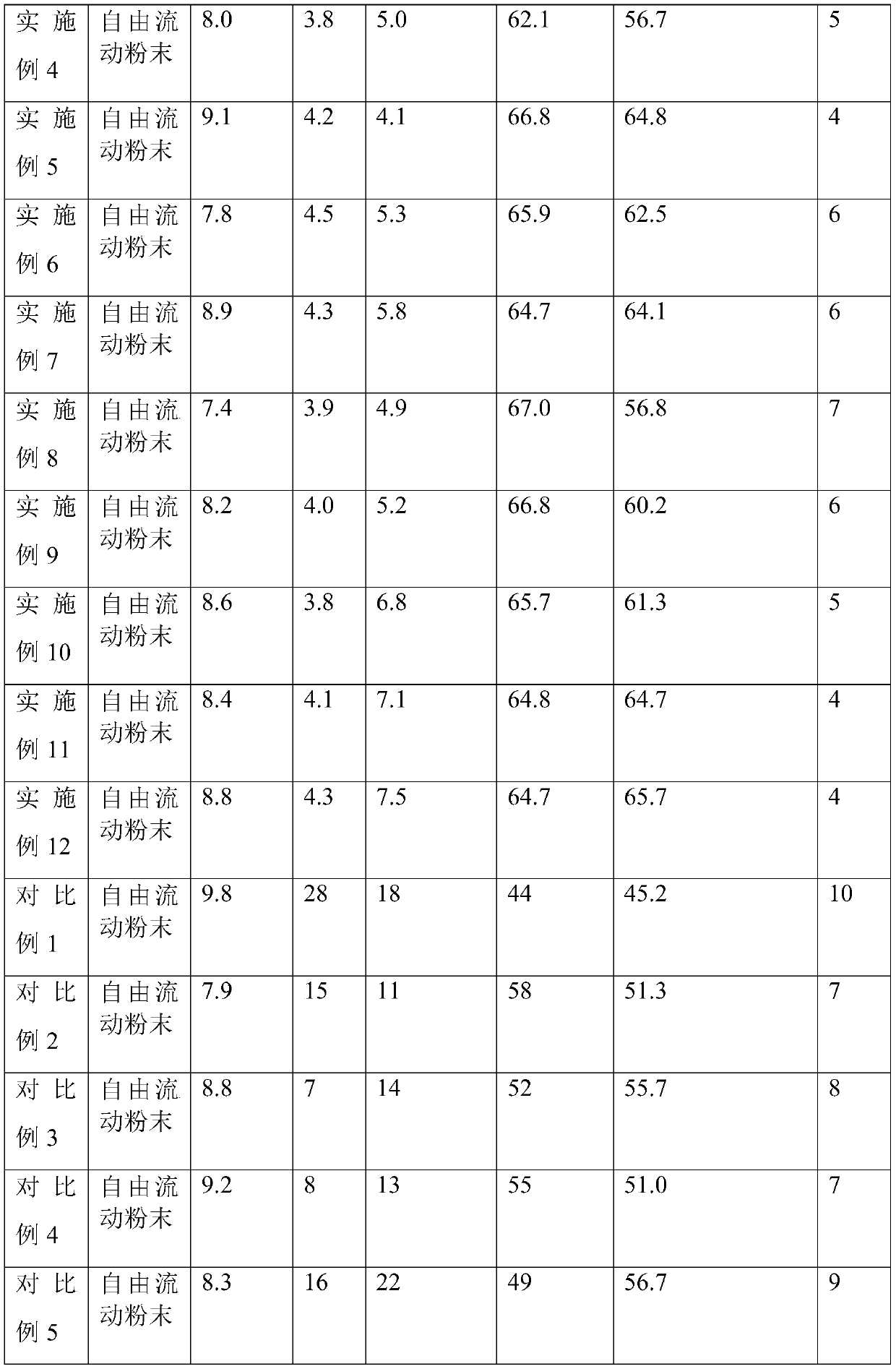

Examples

preparation example 1

[0026] The preparation method of modified polyvinyl alcohol is as follows: mix and stir polyvinyl alcohol and water with a mass ratio of 1:6, raise the temperature to 90°C, and stir at this temperature for 100 minutes, stop stirring, keep warm at 90°C for 1 hour, and then Cool down to 70°C, then add epoxy resin, stir for 15 minutes, then keep warm at 70°C for 2 hours, and dry to obtain modified polyvinyl alcohol.

preparation example 2

[0028] The preparation method of modified polyvinyl alcohol is as follows: mix and stir polyvinyl alcohol and water with a mass ratio of 1:5, heat up to 80°C, and stir at this temperature for 1.5h, stop stirring, and keep warm at 80°C for 1h, Then lower the temperature to 65°C, then add epoxy resin, stir for 10 minutes, keep the temperature at 65°C for 2 hours, and dry to obtain modified polyvinyl alcohol.

preparation example 3

[0030] The preparation method of modified polyvinyl alcohol is as follows: mix and stir polyvinyl alcohol and water with a mass ratio of 1:8, raise the temperature to 100°C, and stir at this temperature for 2 hours, stop stirring, keep warm at 100°C for 1 hour, and then Cool down to 75°C, then add epoxy resin, stir for 20 minutes, then keep warm at 75°C for 2 hours, and dry to obtain modified polyvinyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com