A wallpaper gravure printing slurry capable of purifying indoor air and its preparation method and application

A gravure printing, inner air technology, applied in biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problems of efflorescence, water seepage, affecting the use effect of wallpaper and wall covering, and achieve color improvement , The effect of simple process steps and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

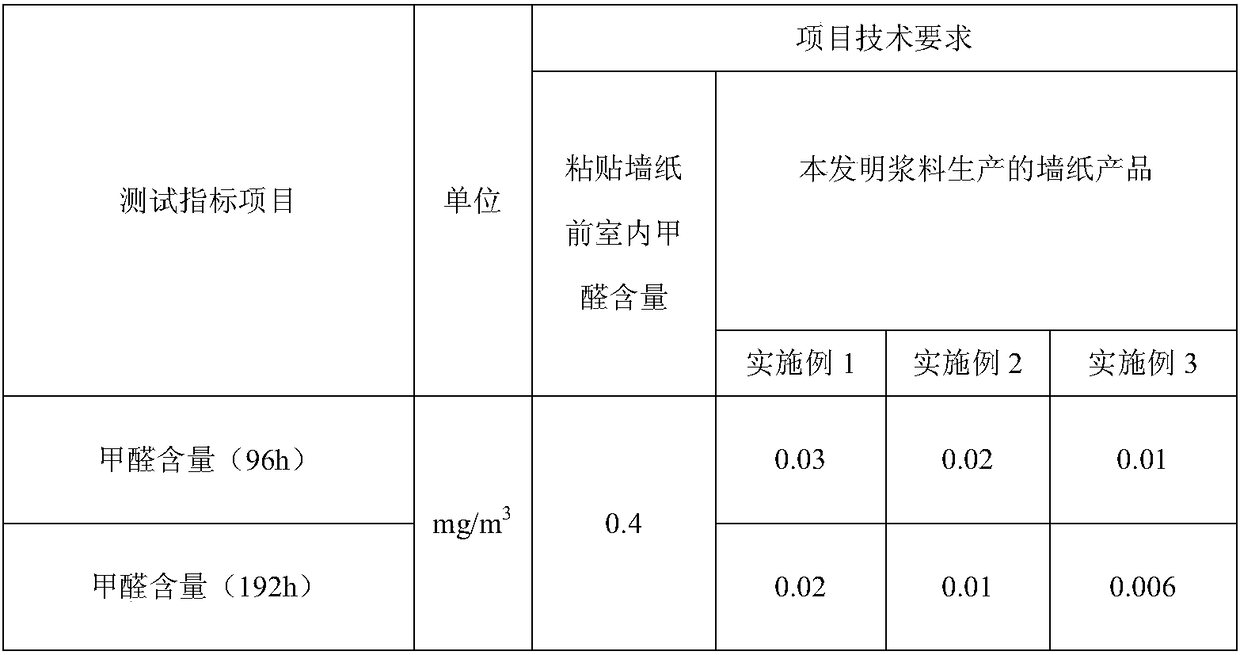

Examples

Embodiment 1

[0028] (1) Preparation of air purification particles

[0029](1) Preparation of pretreated vermiculite powder: mix vermiculite powder, sodium hexametaphosphate and deionized water at a mass ratio of 1:0.03:200, stir and heat to 80°C, soak for 2 hours, stir at a speed of 1000r / min for 30 minutes, filter , dried to obtain dry vermiculite powder; add concentrated sulfuric acid to the dry vermiculite powder according to the mass ratio of 1:1, heat to 85 ° C for 3 hours, filter, wash with deionized water until the pH is neutral, dry, and calcined at 800 ° C , to obtain pretreated vermiculite powder;

[0030] (2) Preparation of composite carbon sol: furfural, water-soluble phenolic resin, carbon nanotubes, carboxymethyl cellulose, brucite fiber, sodium bicarbonate and deionized water in a mass ratio of 3:1:0.3:0.1:0.03 : 0.01: 100 mixed, mixed evenly, dripped ammonia water with a concentration of 0.25mol / L under stirring conditions, and the dropping rate was controlled at 10ml / min,...

Embodiment 2

[0038] (1) Preparation of air purification particles

[0039] (1) Preparation of pretreated vermiculite powder: mix vermiculite powder, sodium hexametaphosphate and deionized water at a mass ratio of 2:0.04:210, stir and heat to 85°C, soak for 3 hours, stir at a speed of 1200r / min for 35 minutes, filter , dried to obtain dry vermiculite powder; add concentrated sulfuric acid to the dry vermiculite powder according to the mass ratio of 1:1.5, heat to 87 ° C for 3 to 5 hours, filter, wash with deionized water until the pH is neutral, dry, and dry at 850 Calcined at ℃ to get pretreated vermiculite powder;

[0040] (2) Preparation of composite carbon sol: furfural, water-soluble phenolic resin, carbon nanotubes, carboxymethyl cellulose, brucite fiber, sodium bicarbonate and deionized water in a mass ratio of 4:1.5:0.4:0.12:0.04 : 0.02: 110 mixing, after mixing evenly, drip ammonia water with a concentration of 0.45mol / L under stirring conditions, the dropping rate is controlled a...

Embodiment 3

[0048] (1) Preparation of air purification particles

[0049] (1) Preparation of pretreated vermiculite powder: mix vermiculite powder, sodium hexametaphosphate and deionized water at a mass ratio of 3:0.05:220, stir and heat to 90°C, soak for 4 hours, stir at a speed of 1500r / min for 40 minutes, filter , dried to obtain dry vermiculite powder; add concentrated sulfuric acid to the dry vermiculite powder according to the mass ratio of 1:2, heat to 90 ° C for 5 hours, filter, wash with deionized water until the pH is neutral, dry, and calcined at 900 ° C , to obtain pretreated vermiculite powder;

[0050] (2) Preparation of composite carbon sol: furfural, water-soluble phenolic resin, carbon nanotubes, carboxymethyl cellulose, brucite fiber, sodium bicarbonate and deionized water in a mass ratio of 5:2:0.5:0.2:0.05 : 0.03: 120 mixed, mixed evenly, dripped ammonia water with a concentration of 0.75mol / L under stirring conditions, the dropping rate was controlled at 20ml / min, un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com