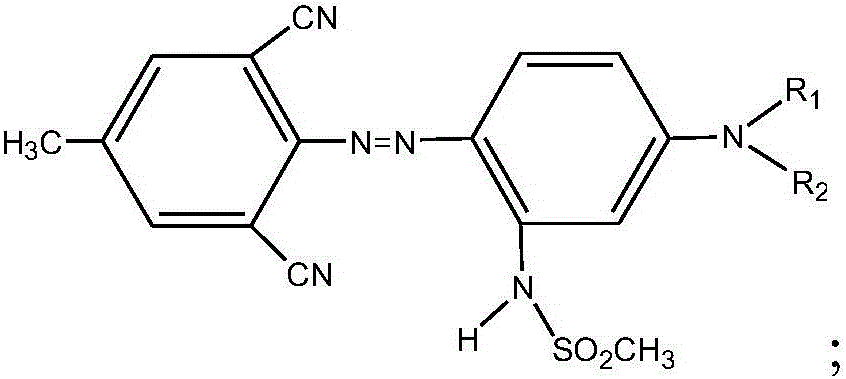

Disperse dye composition used for cellulose triacetate fibers

A technology of disperse dyes and compositions, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of poor thermal stability, unstable dyeing process, poor composition compatibility and color synchronization, etc. Good rubbing fastness, environmentally friendly dyeing performance, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The disperse dye composition that is used for triacetose of the present embodiment is prepared according to the following steps:

[0038] Weigh components A, B, C, and D according to the raw materials and proportions in Table 1, and mix them uniformly to obtain mixture 1, then weigh the additives according to the raw materials and proportions in Table 3, and add them to the mixture 1. Mix evenly to obtain mixture 2. Add water to the mixture 2 and grind and disperse it with a sand mill to obtain a disperse dye composition for triacetose; wherein, the mass ratio of the auxiliary agent to the dye part is 3:7.

Embodiment 2

[0040] The disperse dye composition for triacetose of the present embodiment is different from Example 1 in that: after grinding and dispersing, spray drying is carried out to obtain a powdery disperse dye composition; the process conditions of spray drying are: inlet temperature The temperature is 125°C, and the outlet temperature is 60°C. After drying, a disperse dye composition with a particle size of 1 μm is obtained.

Embodiment 3

[0042] The disperse dye composition for triacetose of this embodiment differs from that of Example 2 in that: the spray drying process conditions are: inlet temperature 130°C, outlet temperature 60°C, after drying, the particle size is 0.5 μm disperse dye composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com