Wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel and manufacturing method thereof

A manufacturing method and technology of polyvinyl chloride, which are applied in the field of wood-plastic composite materials and furniture decoration materials, can solve the problems of poor flame retardancy and fire resistance, poor interface compatibility, flame retardancy and mechanical strength to be further improved, and increase production Simple and efficient effect of cost and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

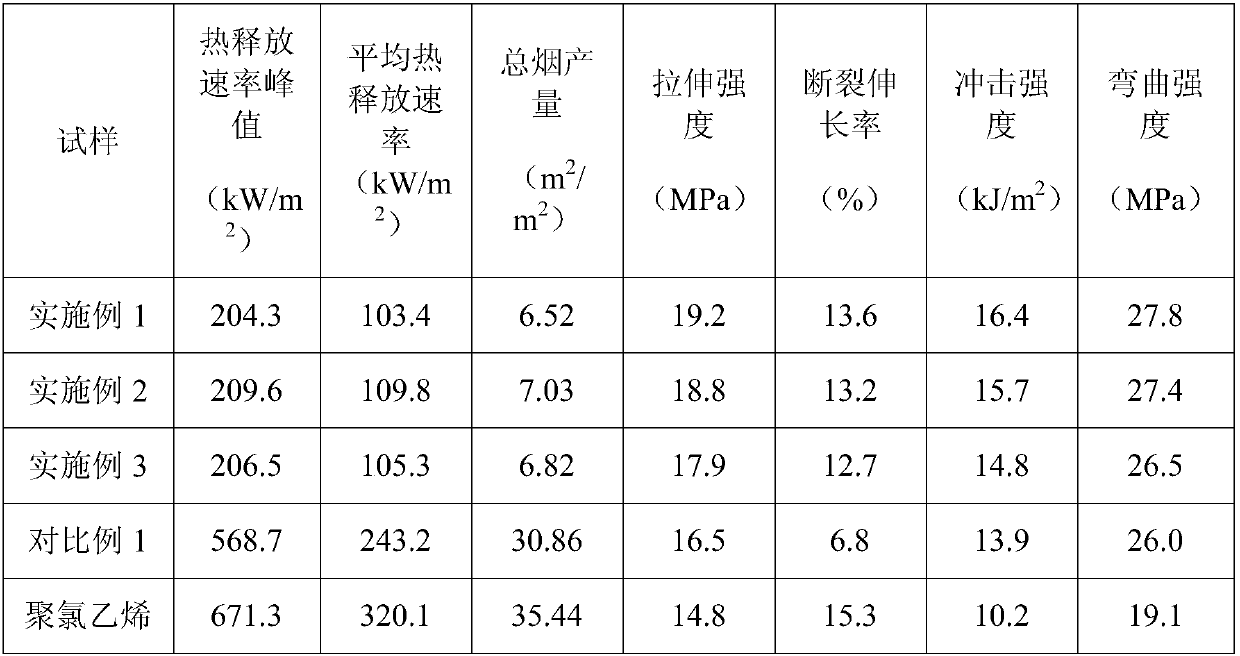

Embodiment 1

[0043] A kind of embodiment of wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel and its manufacturing method of the present invention, wherein, the raw material of manufacturing this wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door comprises: PVC (polyvinyl chloride) resin 90kg, wood Fiber 100kg, phosphoric acid 9kg, light calcium carbonate 90kg, AC-1600 foaming agent 2kg, silane coupling agent A-172 10kg, melamine resin 60kg, chlorinated paraffin 11kg, dioctyl phthalate (DOP) 7kg, Stearic acid 9kg and calcium zinc stabilizer 6kg.

[0044] The manufacturing method of the wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel comprises the following steps:

[0045] (1) Phosphorylation of wood fibers: Input wood fibers into a high-low speed mixing mixer for stirring, spray atomized phosphoric acid into the wood fibers with a pneumatic atomizer, and stir at high speed for 8 minutes, so that the wo...

Embodiment 2

[0053] An embodiment of the wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel and its manufacturing method of the present invention, wherein the raw materials for manufacturing the wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel include: PVC resin 100kg, wood fiber 90kg, phosphoric acid 8kg , light calcium carbonate 90kg, AC-1600 foaming agent 2kg, silane coupling agent A-172 10kg, melamine resin 60kg, chlorinated paraffin 11kg, dioctyl phthalate 7kg, stearic acid 9kg and calcium zinc stabilizer Dosage 6kg.

[0054] The manufacturing method of the wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel comprises the following steps:

[0055] (1) Phosphorylation of wood fibers: Input wood fibers into a high-low speed mixing mixer for stirring, spray atomized phosphoric acid into the wood fibers with a pneumatic atomizer, and stir at high speed for 8 minutes, so that the wood fibers can even...

Embodiment 3

[0063] An embodiment of the wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel and its manufacturing method of the present invention, wherein the raw materials for manufacturing the wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel include: 100 kg of PVC resin, 120 kg of wood fiber, and 10 kg of phosphoric acid , light calcium carbonate 80kg, AC-1600 foaming agent 2kg, silane coupling agent A-172 11kg, melamine resin 80kg, chlorinated paraffin 11kg, dioctyl phthalate 7kg, stearic acid 9kg and calcium zinc stabilizer Dosage 6kg.

[0064] The manufacturing method of the wood fiber reinforced polyvinyl chloride imitation solid wood cabinet door panel comprises the following steps:

[0065] (1) Phosphorylation of wood fibers: Input wood fibers into a high-low speed mixing mixer for stirring, spray atomized phosphoric acid into the wood fibers with a pneumatic atomizer, and stir at high speed for 8 minutes, so that the wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com