Sintering process of super thick large-sized LTCC substrate based on silver system material

A large-scale, systematic technology, applied in the field of sintering technology, can solve problems such as unqualified flatness of the substrate, open circuit of the circuit network, etc., achieve the effect of shortening the sintering time, reducing the probability of open circuit failure, and reducing the sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

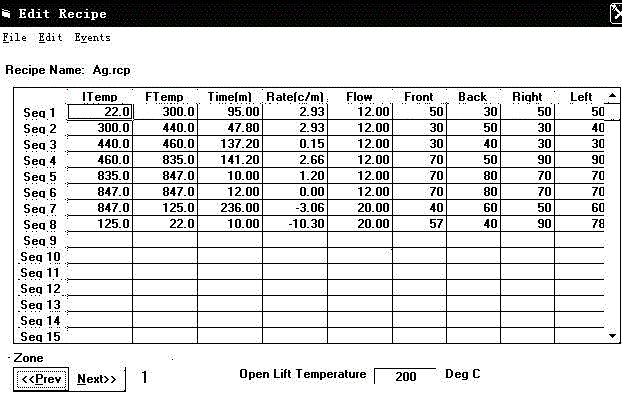

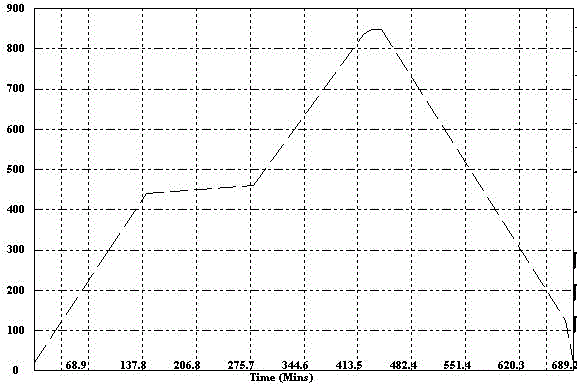

[0029] The technical scheme of the patent application for the present invention is:

[0030] 1) When designing the process, consider the thickness and size of the substrate, and increase the deglue time appropriately;

[0031] 2) Considering the activity of Ag ions, the sintering time above 450°C should be appropriately shortened;

[0032] 3) In order to facilitate the discharge of sintering gas, the sintering support is made of porous alumina;

[0033] 4) Combined with the specific number of layers, size, and whether the product contains cavities, make appropriate adjustments to the five temperature zones of the sintering curve.

[0034] This discovery is mainly applicable to the sintering o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com