Thermal insulation mortar and production method thereof

A technology of thermal insulation mortar and glass fiber, applied in the field of construction mortar, can solve the problem of easy cracking of thermal insulation mortar, and achieve the effects of strong adhesion, improved tensile strength and wear resistance, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

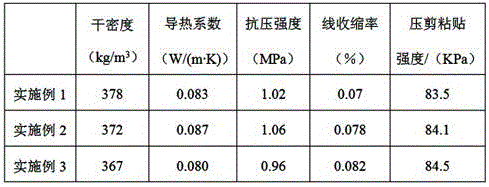

Examples

Embodiment 1

[0013] The thermal insulation mortar in this example is prepared from the following raw materials in parts by weight: 50 parts of expanded perlite, 15 parts of cement, 14 parts of river sand, 20 parts of fly ash, 4 parts of polypropylene particles, 3 parts of glass fiber, modified 1 part of seaweed, 2 parts of anti-cracking agent; wherein, the anti-cracking agent is mixed by hydrogenated castor oil, calcium sulfoaluminate and epoxy resin, and the mass ratio of hydrogenated castor oil, calcium sulfoaluminate and epoxy resin is 1 : 3: 7; The diameter of the glass fiber in this embodiment is 6 microns, and the length is 7 nanometers.

[0014] The method for making thermal insulation mortar in this embodiment is characterized in that it includes the following steps: adding expanded perlite, river sand, and fly ash to a pulverizer for grinding, adjusting the rotating speed to 100r / min, and grinding for 5 hours to obtain granules A mixture with a thickness of 1mm; then mix evenly wi...

Embodiment 2

[0017] The thermal insulation mortar in this example is prepared from the following raw materials in parts by weight: 55 parts of expanded perlite, 12 parts of cement, 12 parts of river sand, 23 parts of fly ash, 6 parts of polypropylene particles, 5 parts of glass fiber, modified 1.5 parts of seaweed, 4 parts of anti-cracking agent; wherein, the anti-cracking agent is mixed by hydrogenated castor oil, calcium sulfoaluminate and epoxy resin, and the mass ratio of hydrogenated castor oil, calcium sulfoaluminate and epoxy resin is 1 : 4: 3.5; The diameter of the glass fiber in this embodiment is 15 microns, and the length is 5 nanometers.

[0018] The method for making thermal insulation mortar in this embodiment is characterized in that it includes the following steps: adding expanded perlite, river sand, and fly ash to a pulverizer for grinding, adjusting the rotating speed to 100r / min, and grinding for 5 hours to obtain granules A mixture with a thickness of 0.7mm; then mix e...

Embodiment 3

[0021] The thermal insulation mortar in this example is prepared from the following raw materials in parts by weight: 60 parts of expanded perlite, 10 parts of cement, 17 parts of river sand, 28 parts of fly ash, 8 parts of polypropylene particles, 7.5 parts of glass fiber, modified 1.2 parts of seaweed, 5 parts of anti-cracking agent; wherein, the anti-cracking agent is mixed by hydrogenated castor oil, calcium sulfoaluminate and epoxy resin, and the mass ratio of hydrogenated castor oil, calcium sulfoaluminate and epoxy resin is 1 : 5: 5; The glass fiber in this embodiment has a diameter of 10 microns and a length of 10 nanometers.

[0022] The method for making thermal insulation mortar in this embodiment is characterized in that it includes the following steps: adding expanded perlite, river sand, and fly ash to a pulverizer for grinding, adjusting the rotating speed to 100r / min, and grinding for 5 hours to obtain granules The mixture with a thickness of 0.5mm; then mix it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com