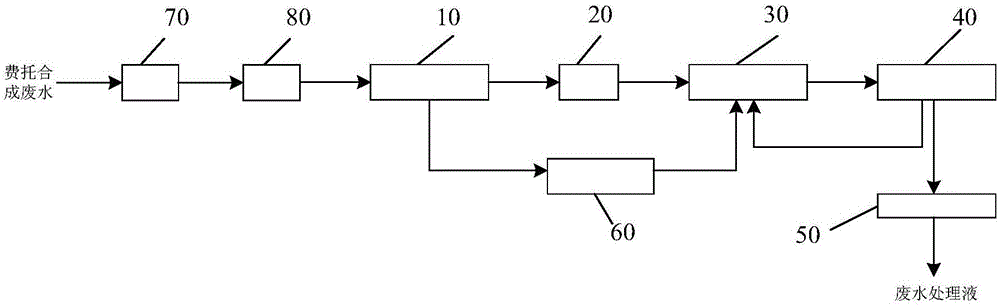

Treatment system and treatment method for Fischer-Tropsch synthesis wastewater

A technology of Fischer-Tropsch synthesis wastewater and treatment system, which is applied in the field of Fischer-Tropsch synthesis wastewater treatment system, can solve the problems of difficult to reach the standard of treated water quality, low water recovery rate, excessive alkali addition and other problems, and achieves good organic matter removal rate, high Operational efficiency, the effect of raising the pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Firstly, the Fischer-Tropsch synthetic wastewater is pretreated by sequentially using the degreasing filter and the ultrafiltration membrane module. The COD content of the treated Fischer-Tropsch synthetic wastewater is reduced from 50,000mg / L to 30,000mg / L. The contents of various substances in the wastewater are as follows: Methanol 1.4wt%, ethanol 2.2wt%, propanol 0.5wt%, butanol 0.2wt%, acetone 0.08wt%, acetic acid 0.5wt%; secondly, the Fischer-Tropsch synthesis wastewater after pretreatment is added to the separation of the electrodialysis device Chamber, add deionized water to the concentration chamber of the electrodialyzer, and add 0.3mol / L Na 2 SO4 The solution is fed into the pole chamber of the electrodialysis unit. When the electrodialysis DC power supply is 10V and the flow rate is 36L / h, the content of other substances in the wastewater is basically unchanged, the content of organic acids is reduced from 0.5wt% to 0.05wt%, and the removal rate is 90%; the ...

Embodiment 2

[0053] Firstly, the Fischer-Tropsch synthetic wastewater is pretreated by sequentially using oil removal filters and ultrafiltration membrane modules. The COD content of the treated Fischer-Tropsch synthetic wastewater is reduced from 60,000 mg / L to 38,000 mg / L. The contents of various substances in the wastewater are as follows: Methanol 1.3wt%, ethanol 2.3wt%, propanol 0.6wt%, butanol 0.1wt%, acetone 0.07wt%, acetic acid 0.6wt%; secondly, the Fischer-Tropsch synthesis wastewater after pretreatment is added to the separation of the electrodialysis device Chamber, add deionized water to the concentration chamber of the electrodialyzer, and add 0.3mol / L Na 2 SO 4 The solution is fed into the pole chamber of the electrodialysis unit. When the electrodialysis DC power supply is 10V and the flow rate is 36L / h, the content of other substances in the wastewater is basically unchanged, the content of organic acids is reduced from 0.6wt% to 0.05wt%, and the removal rate is 91%; the t...

Embodiment 3

[0055] Firstly, the Fischer-Tropsch synthetic wastewater is pretreated by sequentially using the degreasing filter and the ultrafiltration membrane module. The COD content of the treated Fischer-Tropsch synthetic wastewater is reduced from 56000mg / L to 32000mg / L. The contents of various substances in the wastewater are as follows: Methanol 1.5wt%, ethanol 2.1wt%, propanol 0.4wt%, butanol 0.3wt%, acetone 0.09wt%, acetic acid 0.4wt%; secondly, the Fischer-Tropsch synthesis wastewater after pretreatment is added to the separation of the electrodialysis device Chamber, add deionized water to the concentration chamber of the electrodialysis device, and add 0.3mol / L Na 2 SO 4 The solution is fed into the pole chamber of the electrodialysis unit. When the electrodialysis DC power supply is 10V and the flow rate is 36L / h, the content of other substances in the wastewater is basically unchanged, the content of organic acids is reduced from 0.4wt% to 0.035wt%, and the removal rate is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com