Mold system with high/low-temperature rapid conversion function

A fast conversion, low temperature technology, applied in the field of compression molding, can solve problems such as affecting the performance or production efficiency of molded products, excessive heating and cooling conversion time, etc., and achieve the effect of safe demoulding and uniform internal stress distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

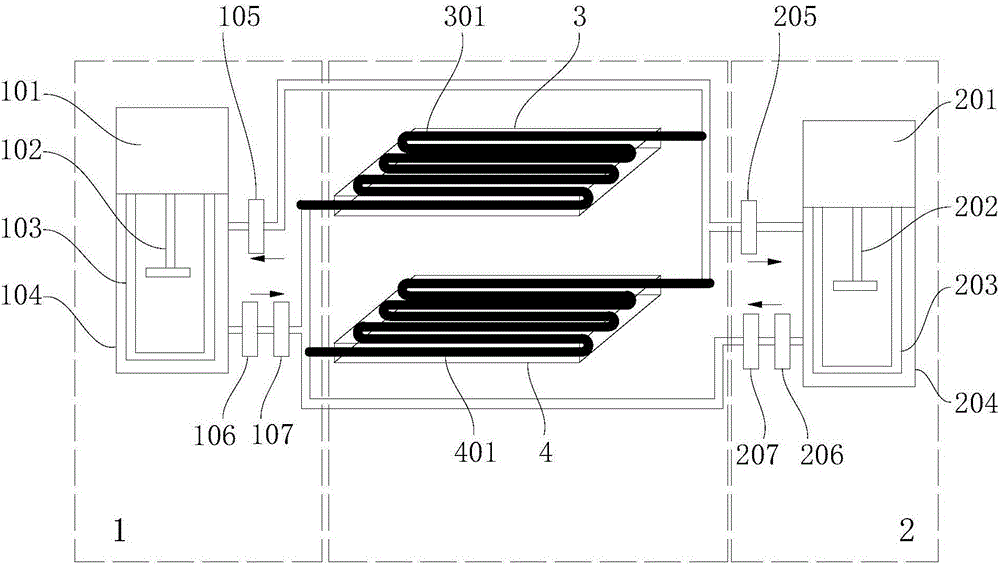

[0025] see figure 1 , a high / low temperature fast switching mold system in the illustration is a preferred embodiment of the present invention, specifically including a high temperature circulation system 1, a low temperature circulation system 2, and a mold assembly composed of an upper mold plate 3 and a lower mold plate 4. An upper die serpentine pipe 301 and a lower die plate 401 are respectively provided inside the upper die plate 3 and the lower die plate 4 for heating or cooling the molding material in the inner cavity of the die. The upper mold serpentine tube 301 and the lower mold serpentine tube 401 respectively form independent circuits with the high temperature circulation system 1 and the cooling circulation system 2, and the high temperature circulation system 1 and the cooling circulation system 2 are heated and cooled by circulating fluid medium , the loop of the high-temperature circulation system and the loop of the low-temperature circulation system are res...

example 1

[0034] Example 1: Preparation of foam sandwich structure flat panel

[0035] In the preparation process of the foam sandwich structure plate in this example, a kind of such as figure 1 The specific preparation method of the high / low temperature rapid conversion mold system shown includes the following steps in sequence:

[0036] 1. Press figure 1 Connect the high / low temperature quick change mold system;

[0037] 2. Close the cryogenic pumping valve 207 and the cryogenic return valve 205;

[0038] 3. Turn on the heater 103 and the high-temperature agitator 102 to uniformly heat the high-boiling liquid (such as silicone oil) in the high-temperature box to 80°C;

[0039] 4. Turn on the cooler 203 and the low-temperature stirrer 202 to uniformly cool the high-boiling liquid (such as silicone oil) in the low-temperature box 204 to 20°C;

[0040] 5. Open the high-temperature pumping valve 107 and the high-temperature return valve 205, so that the high-temperature box and the se...

example 2

[0047] Example 2: Preparation of Glass Fiber Reinforced Thermoplastic Composite (GF / PP)

[0048] The preparation process of the glass fiber reinforced thermoplastic composite material (GF / PP) in this example uses a method such as figure 1 The specific preparation method of the high / low temperature rapid conversion mold system shown includes the following steps in sequence:

[0049] 1. Press figure 1 Connect the high / low temperature quick change mold system;

[0050] 2. Close the cryogenic pumping valve 207 and the cryogenic return valve 205;

[0051] 3. Turn on the heater 103 and the high-temperature agitator 102 to uniformly heat the high-boiling liquid (such as silicone oil) in the high-temperature box to 200°C;

[0052] 4. Turn on the cooler 203 and the low-temperature stirrer 202 to uniformly cool the high-boiling liquid (such as silicone oil) in the low-temperature box 204 to 20°C;

[0053] 5. Open the high-temperature pumping valve 107 and the high-temperature return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com