Method for one-time low-temperature preparation of regenerated rubber

A recycled rubber and low-temperature technology, which is applied in the field of one-time low-temperature preparation of recycled rubber, can solve the problems of low-temperature regeneration without internal mixer, external environmental pollution, and low quality of finished products, so as to ensure physical properties and work efficiency, simplify the desulfurization process, The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0024] Concrete embodiment, the method for preparing regenerated rubber at low temperature comprises the following concrete steps:

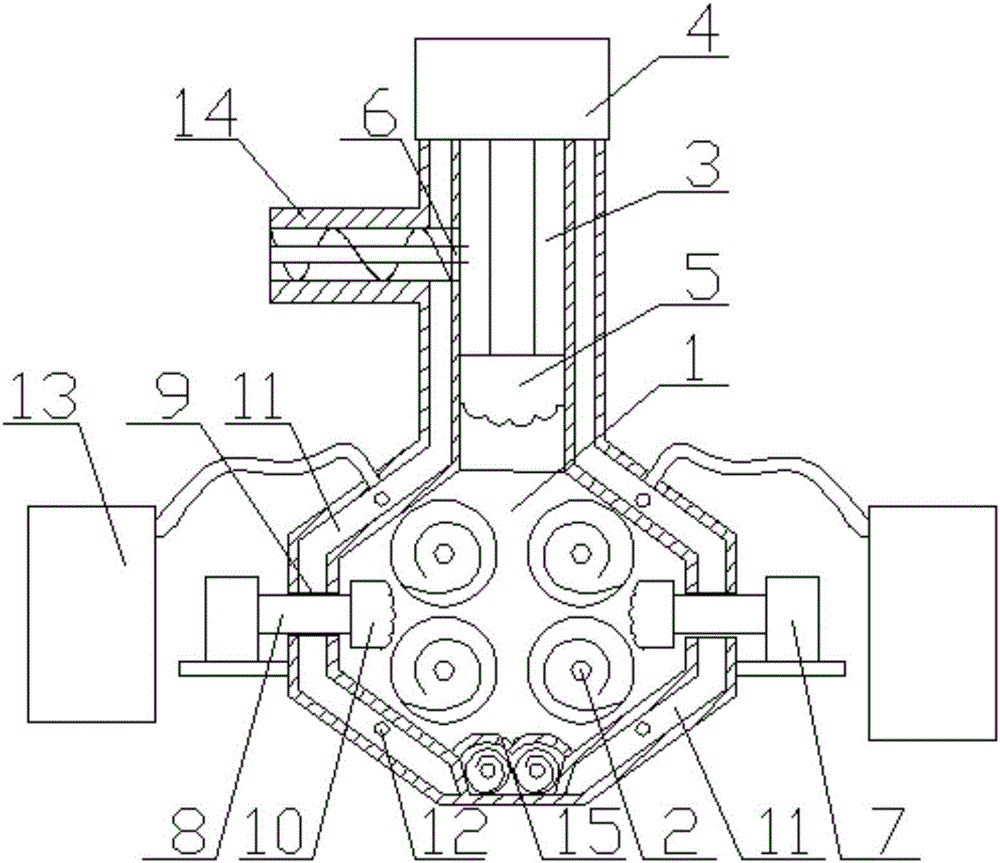

[0025] A. Add 100 parts by weight of 40-100 mesh vulcanized rubber powder, 3 parts of additives, 15 parts of softening oil or carbon black masterbatch into the high-shear internal mixer, such as figure 1 As shown, the internal mixer includes a mixing chamber 1, a feeding mechanism located at the upper end of the mixing chamber 1, a rotor 2 arranged inside the mixing chamber 1, a pressing device passing through the mixing chamber 2, and a The unloading device at the bottom, the feeding mechanism includes a feeding channel 3 and an upper jack bolt 5 that is pulled by a hydraulic cylinder 4 and moves along the feeding channel 3, a feeding port 6 is provided on the side of the feeding channel 3, and the pressing device includes two symmetrically arranged by The pressing rod 8 pulled by the telescopic cylinder 7 is provided with guide holes 9 on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com