Clamping and positioning device for wire electrode of wire-cut electrical discharge machine capable of realizing rapid wire feeding

A cutting machine tool, clamping and positioning technology, applied in the direction of electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of electrode wire shaking, guide wheel groove narrow, electrode wire bending and breaking, etc., to improve accuracy and Efficiency, avoiding easy hand injury, and easy tensioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

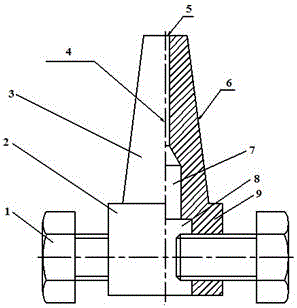

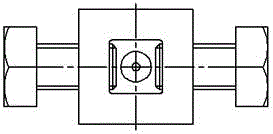

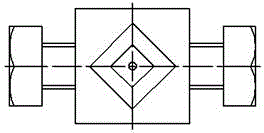

[0023] Combine figure 1 , figure 2 with image 3 As shown, the present invention includes a device body 9. The device body 9 includes a threading part 3 and a clamping part 2 from top to bottom. The top of the threading part 3 is provided with a threading hole 5, and the clamping The bottom of the part 2 is provided with a groove 8, the groove 8 communicates with the threaded hole 5, the two opposite side walls of the clamping part 2 are symmetrically provided with bolts 1, and the ends of the bolts 1 pass through The side wall of the clamping part 2 extends into the groove 8; the threading part 3 is a pyramid structure (in this embodiment, the threading part 3 is a square pyramid structure), and the axis of the threading hole 5 is The center line 4 of the pyramid is collinear; the top section of the pyramid is smaller than the bottom section; the top side of the pyramid is in the range of 3.5~4.5 mm (in this embodiment, the top side of the square pyramid is 4 Mm), the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com