A non-destructive droplet detachment device for micro-sampler

A technology for detaching from the device and micro-sampling, which is applied in the direction of measuring tubes/pipettes, laboratory containers, laboratory utensils, etc., and can solve the problems that micro-samplers cannot drop tiny droplets, etc., and reach the scope of application Wide range, quantitative accuracy, and the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

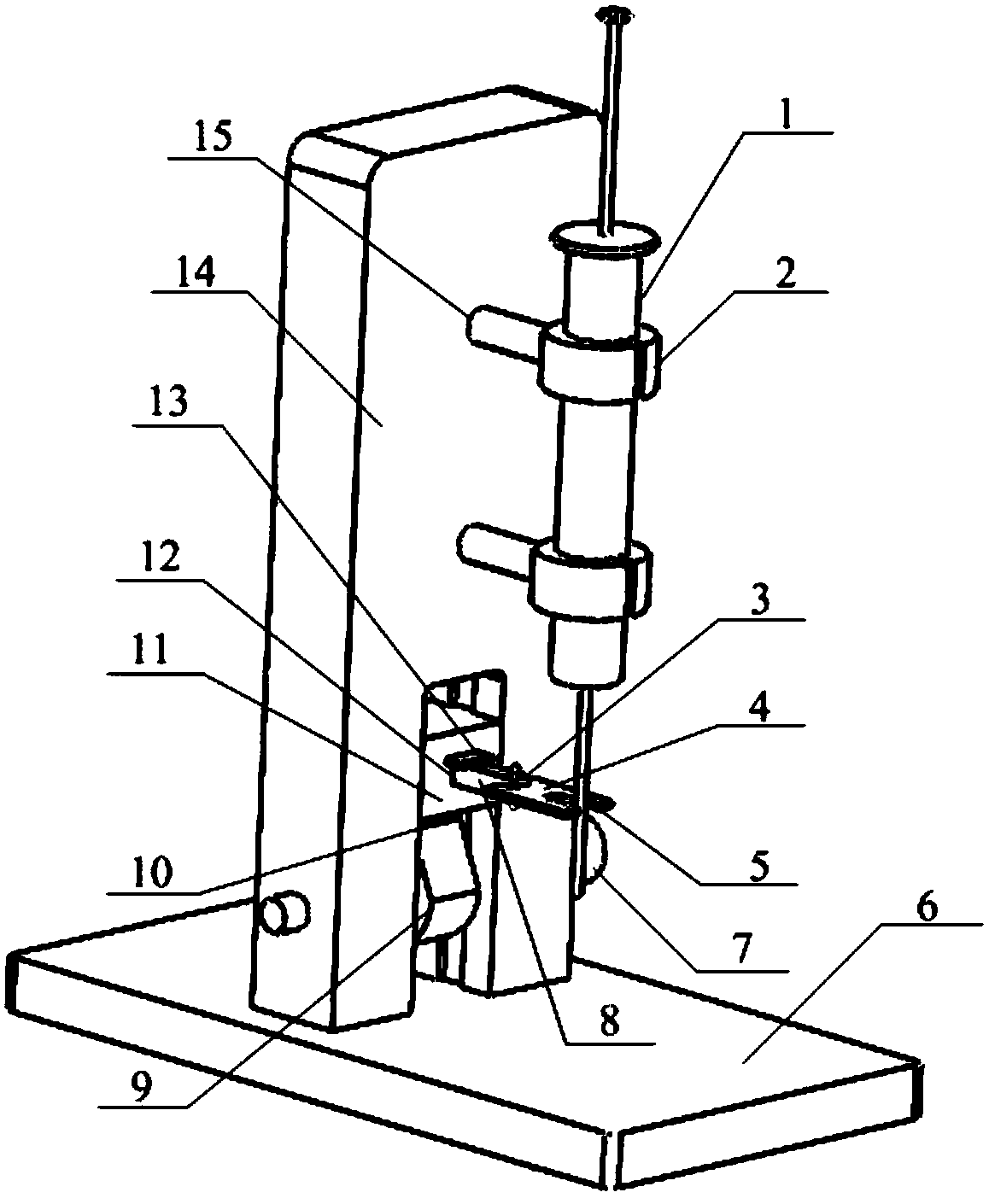

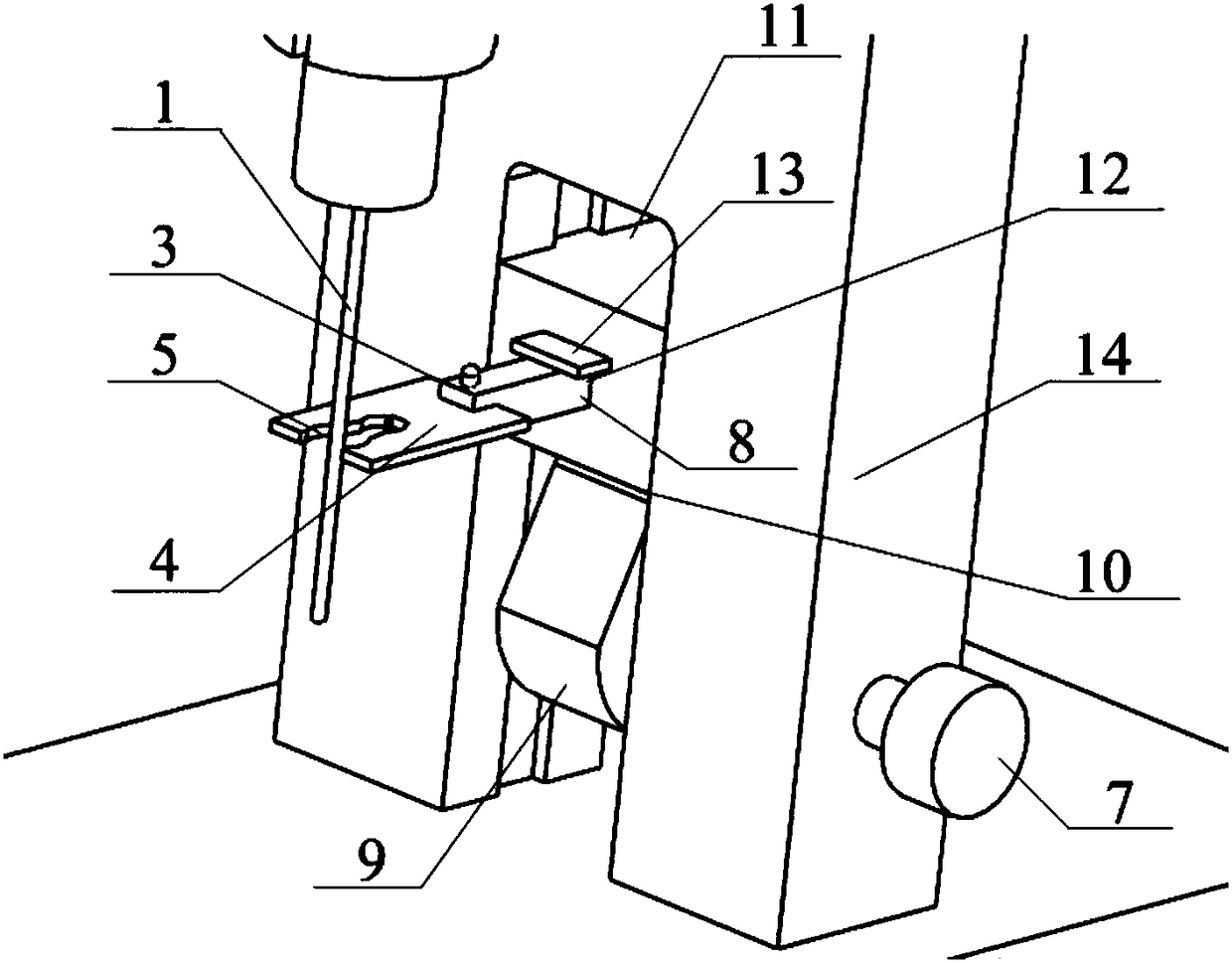

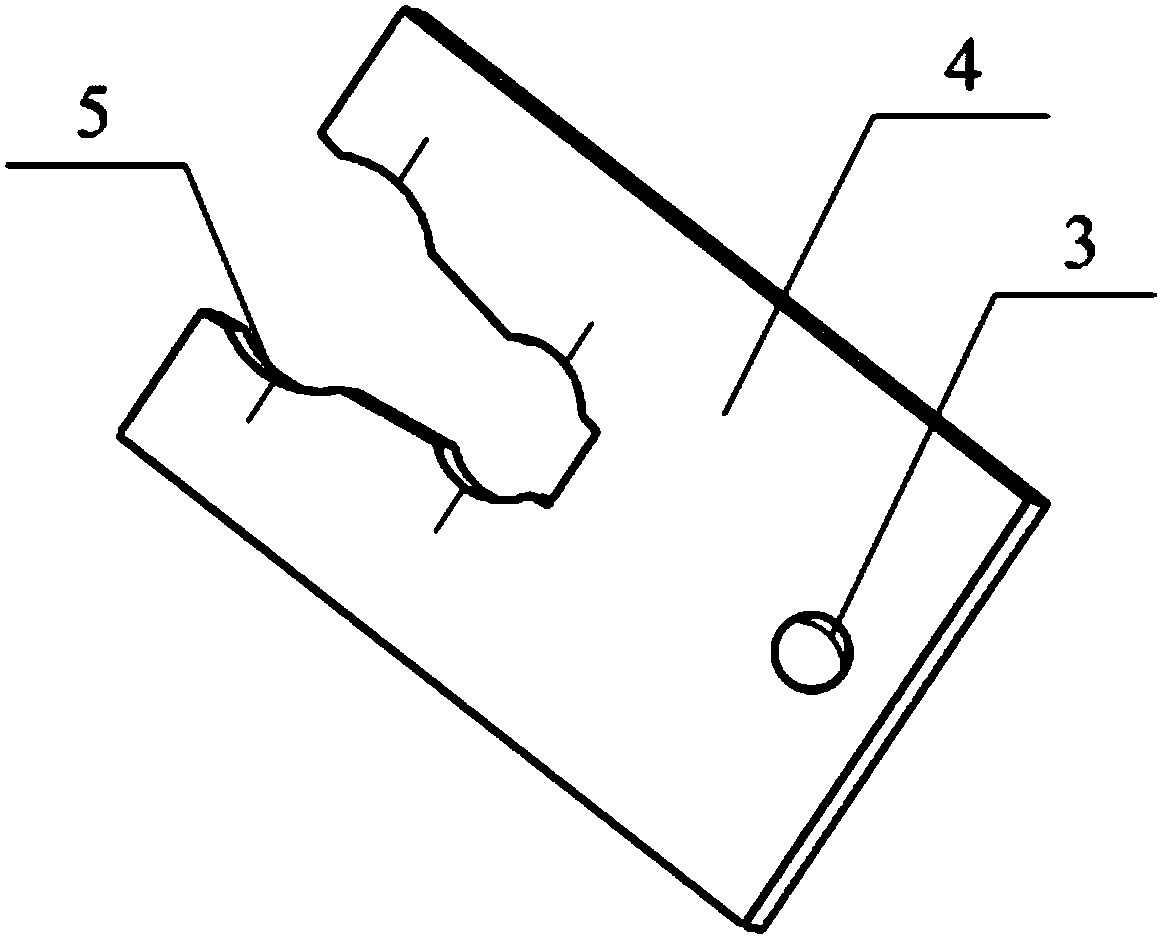

[0030] A droplet detachment device for a microsampler such as figure 1 As shown, it includes a micro-sampling assembly 1 , a bracket assembly 15 , a position adjustment assembly and a super-lyophobic separator sheet 4 . figure 2 Adjust component local structure for position. In this example, water droplets are used as the operating object, and an ordinary micro-sampler with a volume range of 10 μL is used as the sample injection component. The super-lyophobic liquid separator used is an aluminum sheet with a contact angle with water of 160° and a rolling angle of 2°. (6061 aluminum alloy), with pores for 1-8μL and 4-8μL drops respectively, such as image 3 shown. In this embodiment, the side plate and the base plate are fixed to drip liquid.

[0031] After the side panels of the bracket assembly are connected to the base plate, place the base plate horizontally. After the sample injection component absorbs 10 μL of water in the full scale, it is fixed on the clamp on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com