A device and method for manufacturing an organic light emitting display

A light-emitting display, organic technology, applied in the direction of copying/marking methods, electric solid devices, devices for coating liquids on surfaces, etc., can solve the problems of dripping other positions or other pixels, large errors, etc. The effect of bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with the embodiments of the present invention and the accompanying drawings.

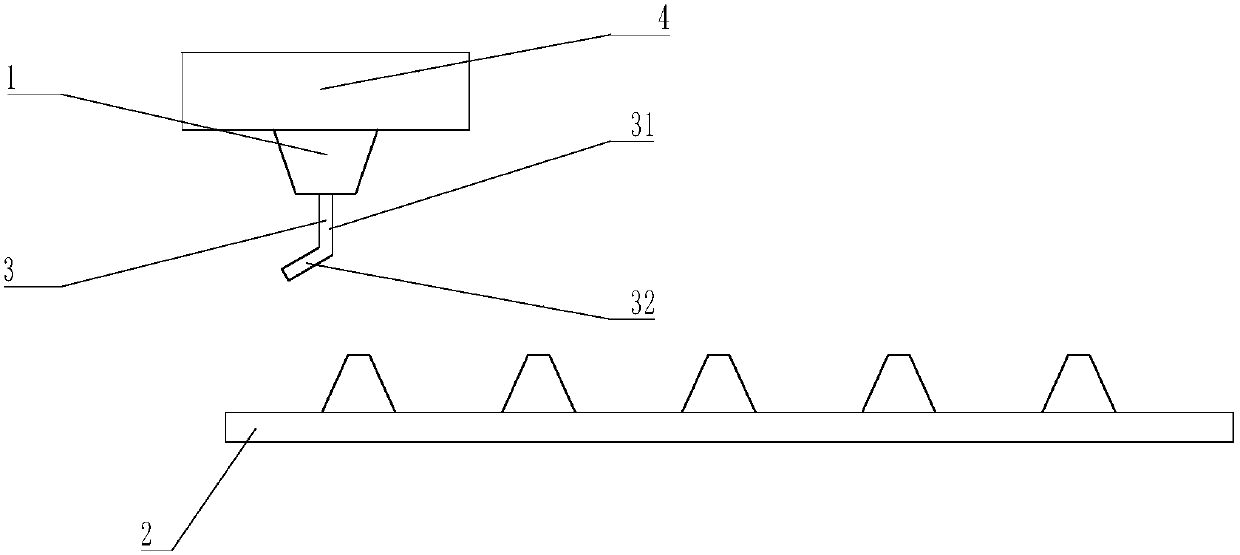

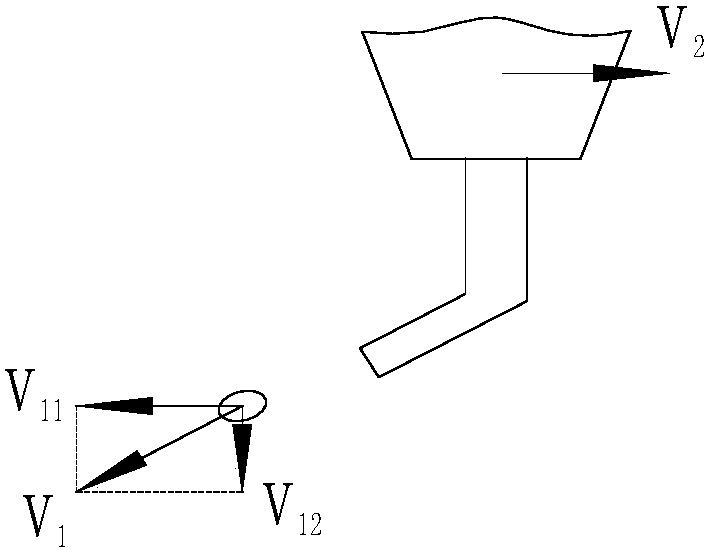

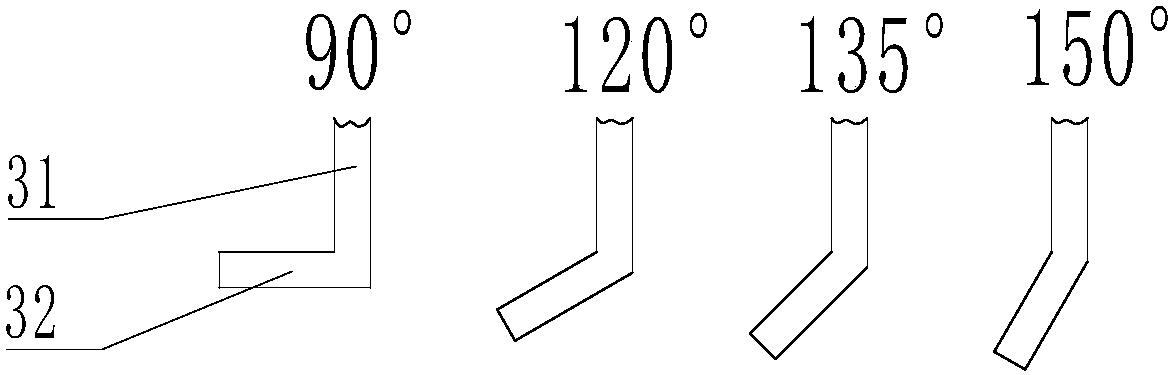

[0021] refer to figure 1 , figure 1 It is a structural schematic diagram of the first embodiment of the manufacturing equipment of an organic light-emitting display according to the present invention. In this embodiment, it includes: a shower head 1 for placing on a substrate 2 and including at least one nozzle 3. The nozzle 3 is used for The ink is ejected to the surface of the substrate 2; the moving unit 4 is used to control the relative movement of the nozzle 1 and the substrate 2.

[0022] In this embodiment, the moving unit 4 controls the shower head 1 to move relative to the substrate 2 along a direction parallel to the surface of the substrate 2 . In other embodiments, the moving unit 4 controls the shower head 1 to move relative to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com