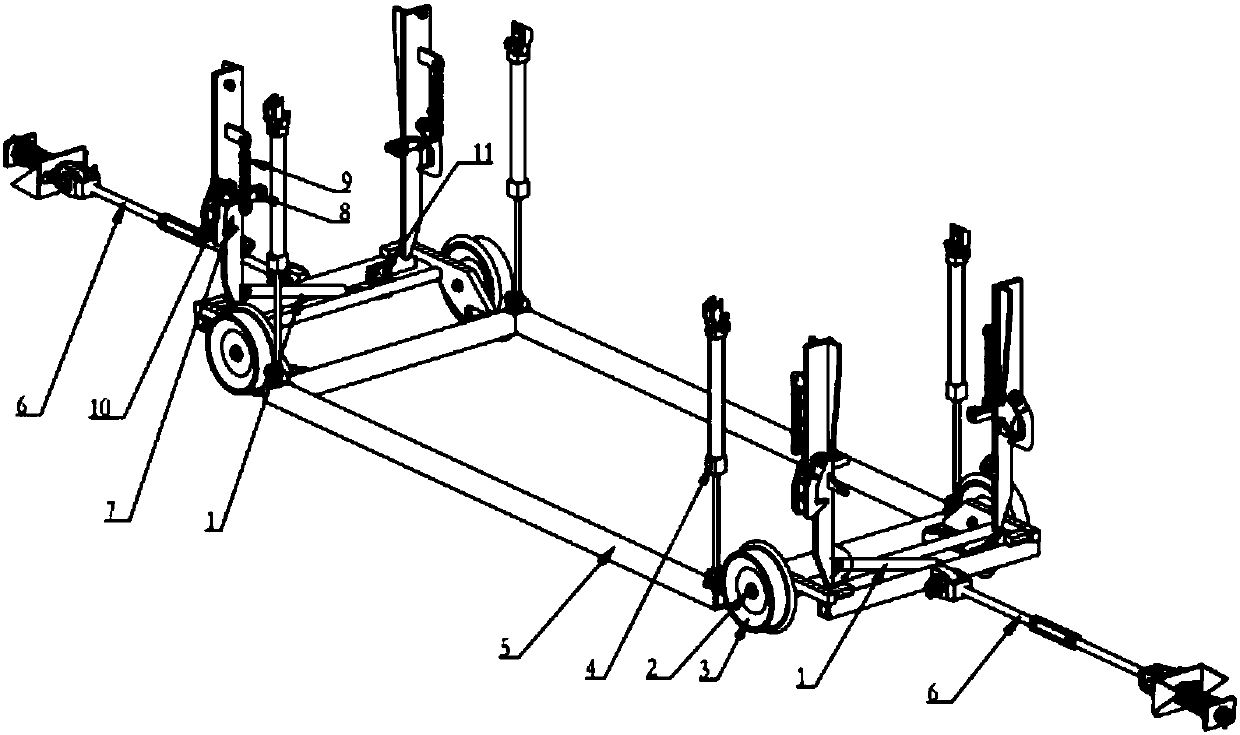

Bidirectional operation type trolley capable of being locked and released at curve section for rail car

A technology for rail cars and trolleys, which is applied in the direction of transporting passenger cars, railway car body parts, traction devices, etc., can solve the problems that the working trolley cannot be retracted and affect the operation efficiency, and achieve the effect of simple structure and convenient installation and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

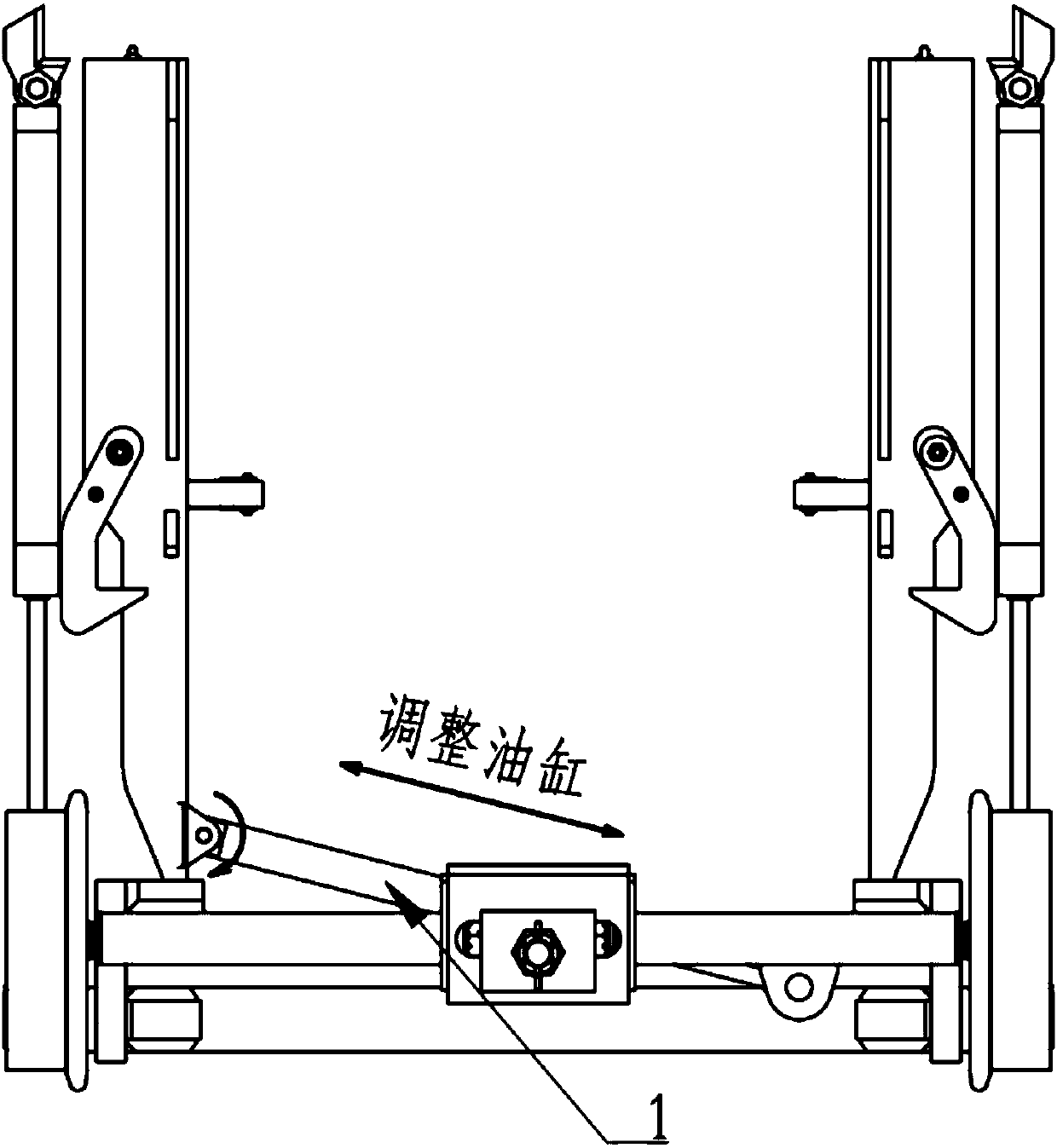

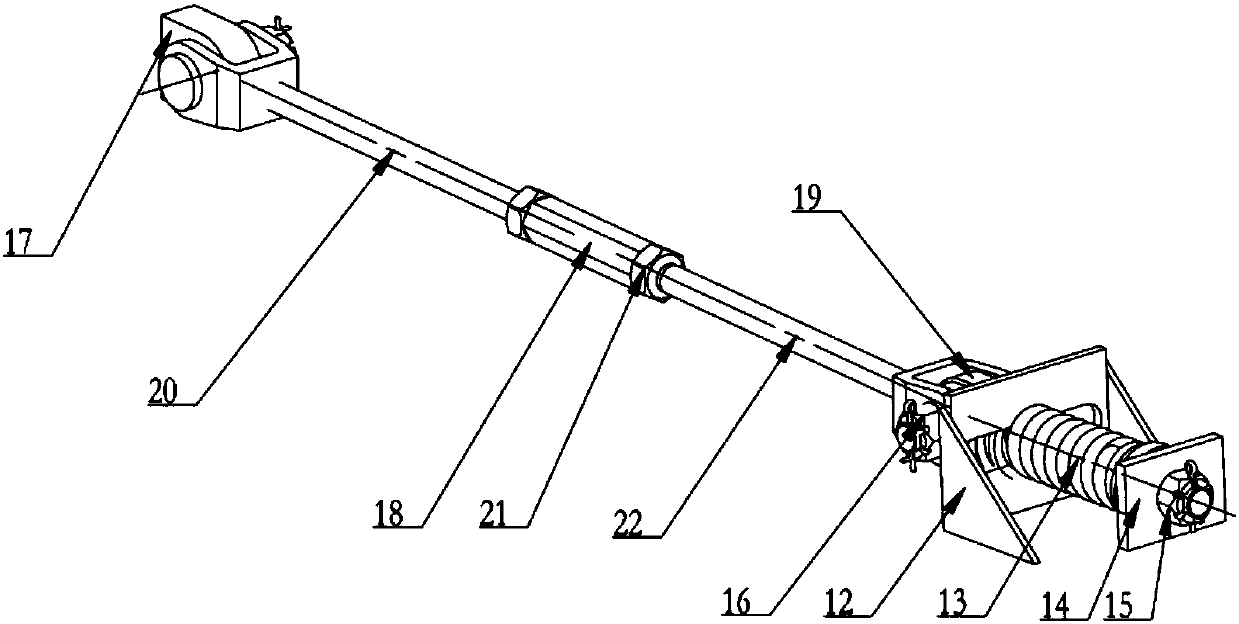

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1.2: a kind of track car can be retractable two-way operation trolley with curve, with embodiment 1.1, the difference is: the center distance of the center of the piston rod seat 25 of the swing cylinder piston rod seat 25 of the trolley is as follows: 155cm.

[0050] Embodiment 1.3: a kind of track car can be retractable two-way operation trolley with curve, with embodiment 1.1, the difference is: the center distance of the center of the piston rod seat 25 of the swing cylinder piston rod seat 25 of the trolley is as follows: 153cm.

[0051] Embodiment 1.4: a kind of track car can be retractable two-way operation trolley with curve, with embodiment 1.1, the difference is: the center distance of the center of the piston rod seat 25 of the swing cylinder piston rod seat 25 of the trolley is as follows: 158cm.

[0052] Embodiment 1.5: a kind of track car can be retractable two-way operation trolley with curve, with embodiment 1.1, the difference is: the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com