Tripod capable of being quickly retracted and expanded

A tripod, fast technology, applied in the direction of the machine/stand, rod connection, connecting components, etc., can solve the problem that the tripod cannot be retracted quickly, and achieve the effect of rapid retraction and simplified retraction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

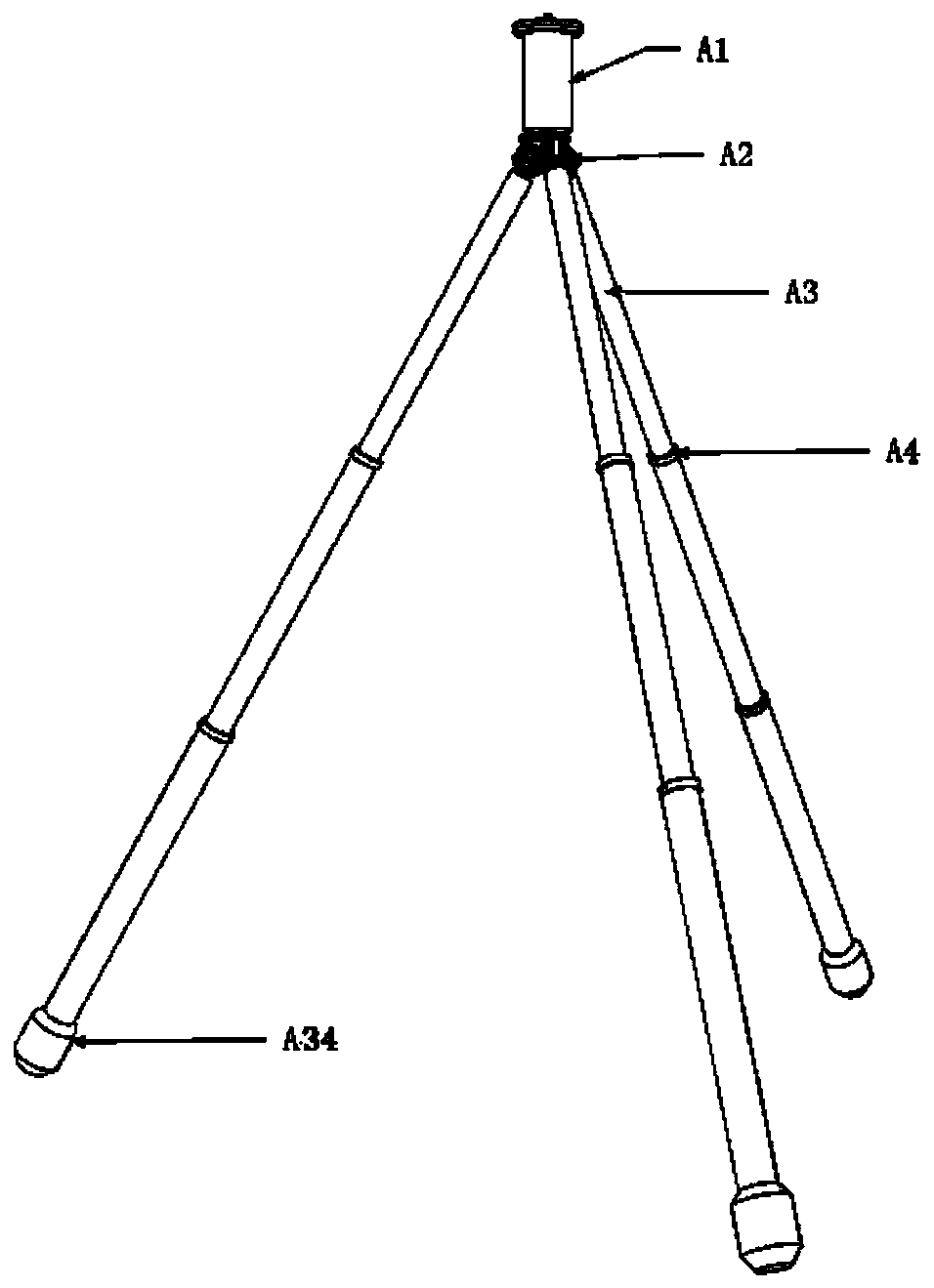

[0092] figure 1 As shown, the tripod consists of four parts: handle A1, bracket A2, outrigger A3 (3 branches, each with 3 sections), and A4 joints (each outrigger has 2 joints, 6 in total).

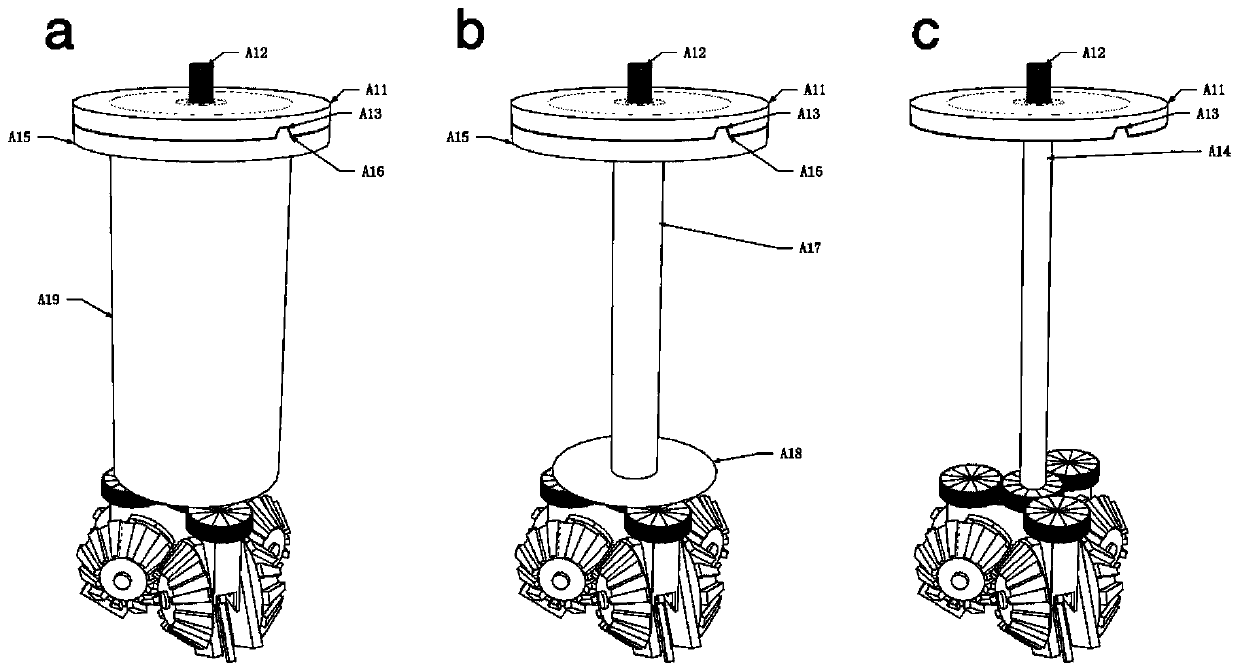

[0093] figure 2 The handle is shown with the tripod joint locked. The operating mechanism of the handle includes a pan-tilt bearing plate, an outer shaft A17, a handle chassis A18, a handle shell A19, a handle upper cover A15 and an inner shaft A14; the upper end of the inner shaft A14 is connected with the pan-tilt bearing plate, and the The outer shaft A17 is sleeved outside the inner shaft A14, the two ends of the outer shaft A17 are respectively connected to the handle chassis A18 and the handle upper cover A15, and the two ends of the handle shell A19 are respectively connected to the handle chassis A18 and the handle upper cover A15; the handle shell The rotation of A19 drives the handle chassis A18 to rotate and then drives the twisting mechanism to rotate. figure 2 where a is...

Embodiment 2

[0102] Figure 8 As shown, the tripod consists of four parts: handle B1, bracket B2, outrigger B3, and joint B4.

[0103] Figure 9 The handle is shown with the tripod joint locked. The operating mechanism of the handle includes a pan-tilt bearing plate B101, a spring leaf B106, a handle shell B104 and a handle bottom shell B105. The bottom end is hinged, the upper end of the handle is hinged to the handle extension rod B109, the handle extension rod B109 is hinged to the longitudinal axis of the handle extension rod B110, and the handle push rod B111 is hinged; the handle push rod B111 is carried by the pan / tilt The gap of disc B103 penetrates into the interior of the pan / tilt bearing disc. There are two nested concentric shafts inside the handle. The inner shaft B118 is fixedly connected to the center of the support B21. The outer shaft sleeve B117 is outside the inner shaft; the top of the outer shaft is fixedly connected to two The same support column B116, the support ...

Embodiment 3

[0114] Figure 17 As shown, the tripod consists of four parts: handle C1, bracket C2, outrigger C3, and joint C4.

[0115] Figure 18 Handle and stand for tripod shown. Figure 18 where a is the external view, Figure 18 b is the inner view. The handle part is exactly the same as that of embodiment 2, and the bracket is completely the same as that of embodiment 1. The bottom of the handle is fixedly connected with the central gear C25. In the state of joint locking, when the handle is pressed for the first time, the bottom of the handle drives the central gear to rotate clockwise, and the transfer gear C26 drives the first transmission shaft to rotate counterclockwise to C36.

[0116] Figure 19 The external and internal views of the first joint of a single outrigger. Figure 19 where a is the external view, Figure 19 Middle b is the positional relationship between the anti-protrusion screw C41 and the first leg C31 after removing the second leg C32, Figure 19 Middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com