Bag packaging method

a bag and packaging technology, applied in the field of bag packaging methods, can solve the problems of large possibility, inability to use packaging using a thin soft plastic bag, and difficulty in sealing the mouth portion without generating creases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

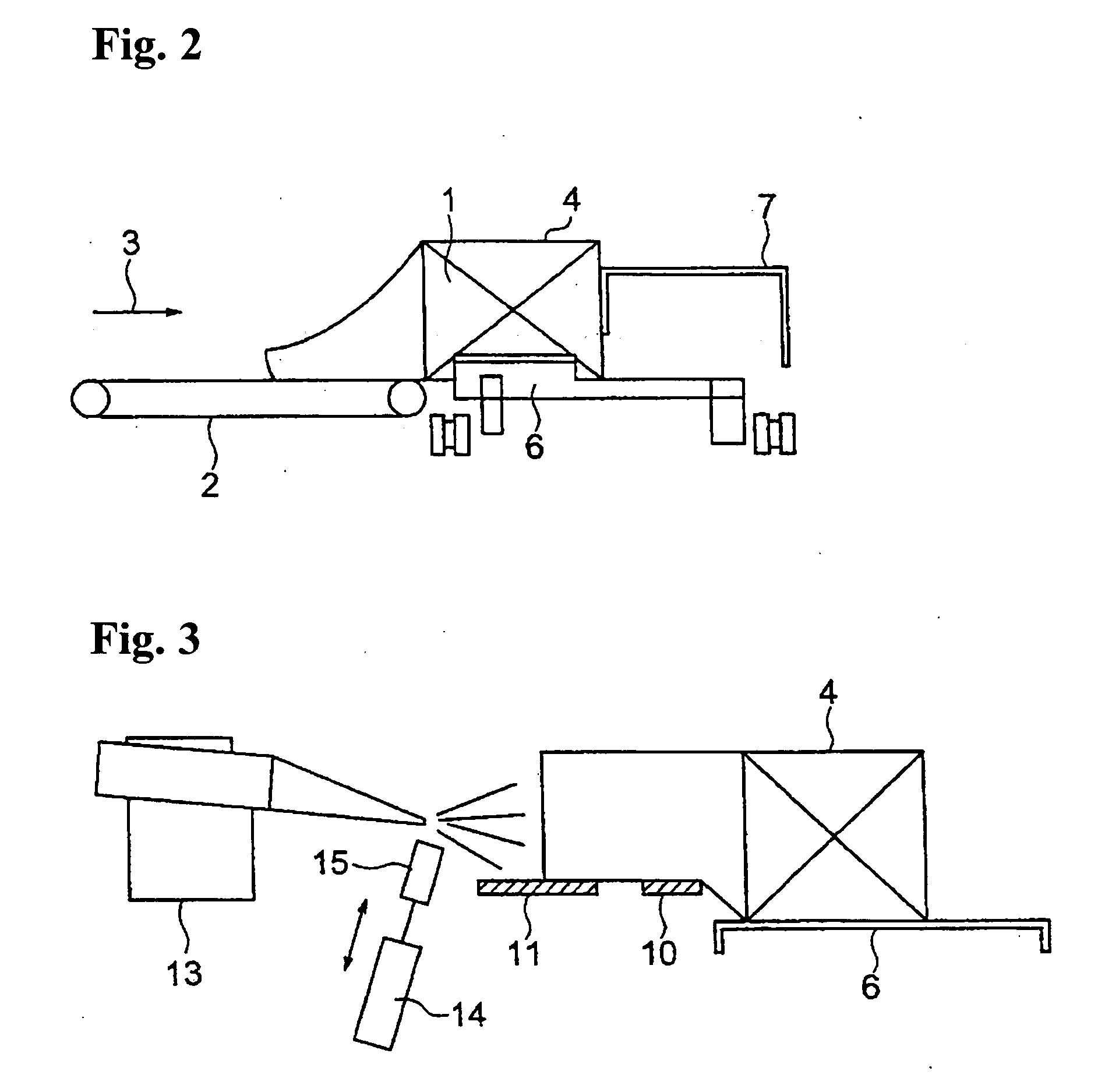

[0026] Herebelow, the present invention will be concretely described based on an embodiment, as illustrated, in which the bag packaging method according to the present invention is applied to packaging of sliced bread using a thin plastic bag.

[0027]FIG. 1 is a plan view showing a construction of a bag packaging apparatus in which the bag packaging method of the present invention is applied to packaging of sliced bread. There, numeral 2 designates a feed conveyor by which a bag 4 from the previous filling step, filled with sliced bread 1 and having its mouth portion to be sealed, is conveyed in the direction of arrow 3, wherein the mouth portion is directed toward the upstream side. Numeral 6 designates a blade conveyor as a carrier conveyor on which the bag 4 filled with the sliced bread 1 is placed to be conveyed. Thus, the bag 4 that has been conveyed by the feed conveyor 2 is further conveyed in the direction of arrow 5, wherein the bag 4 has the mouth portion transversely direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com