Linear actuator convenient to operate

A linear actuator, easy-to-operate technology, applied in the direction of brake type, automatic brake, mechanical drive clutch, etc., can solve the problems of complicated operation and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

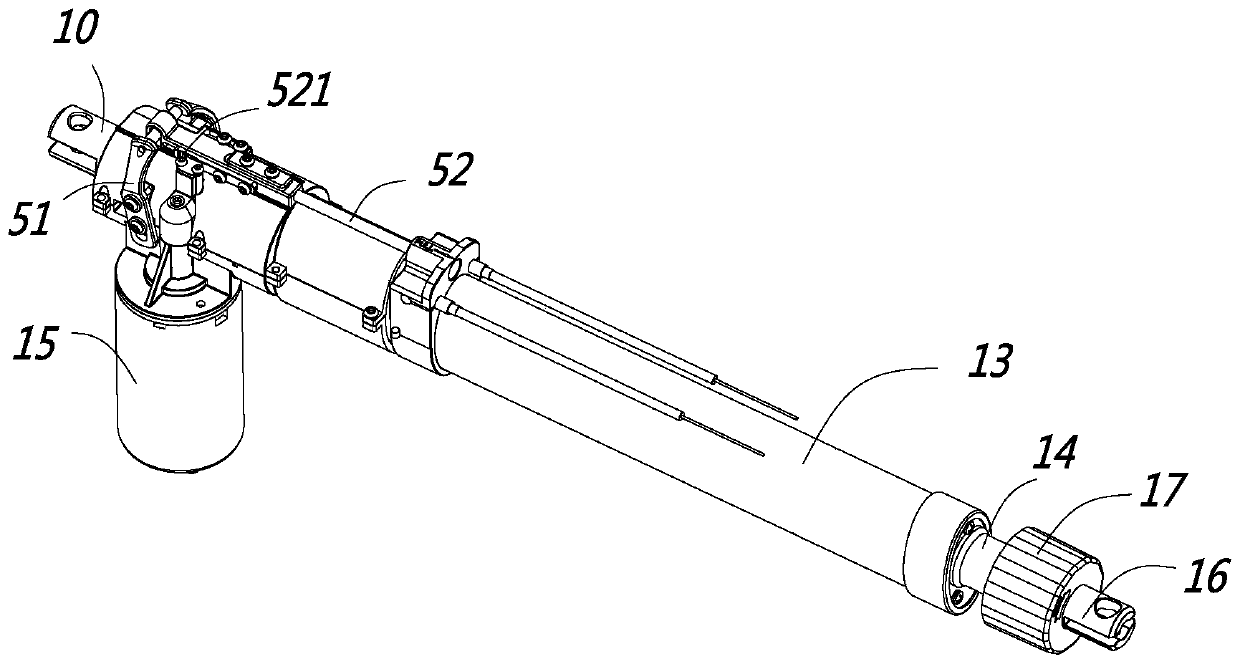

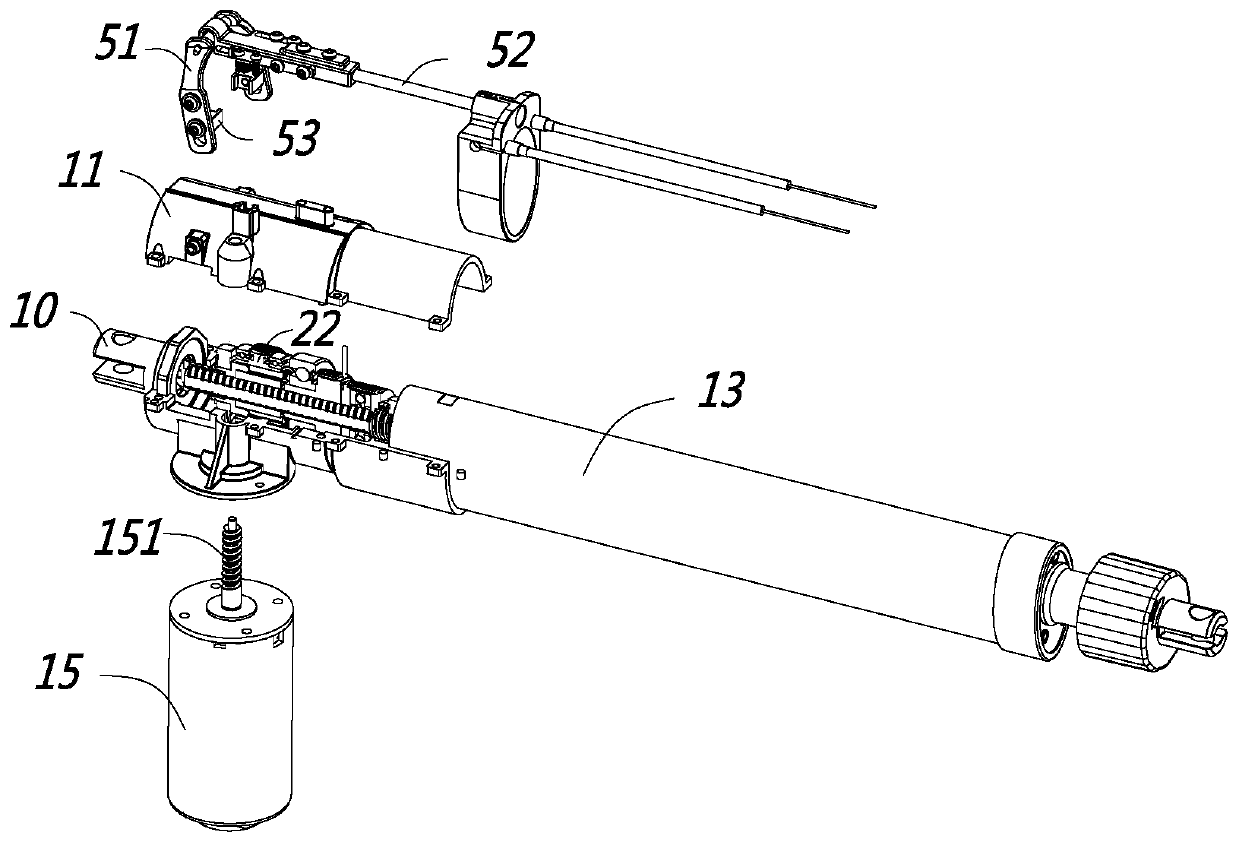

[0041] Such as Figure 1 to Figure 7 As shown, this embodiment is a linear actuator, which is also commonly called a linear actuator or an electric push rod. The linear actuator includes a housing, an outer tube 13, an inner tube 14, a driving motor 15, a transmission assembly, Turn the screw rod 20 and the transmission nut 21, the drive motor 15 drives the rotation screw rod 20 to rotate through the transmission assembly, the rotation of the rotation screw rod 20 drives the transmission nut 21 to move axially along the rotation screw rod 20, and the transmission nut 21 is fixed to the inner tube 14 connected, when the drive nut 21 moves axially, it drives the inner tube 14 to move axially relative to the outer tube 13 and the outer shell, and the outer end of the inner tube 14 is connected to the object to be driven. The linear actuator in this embodiment also include:

[0042] The clutch device is arranged between the transmission assembly and the rotating screw mandrel 20,...

Embodiment 2

[0068] Such as Figure 8 to Figure 11 As shown, the general operation principle of the present embodiment is similar to that of the first embodiment, except that there are differences in the specific structures of the self-locking device, the clutch device, the first driving member, and the second driving member.

[0069] The self-locking device of this embodiment: in the first embodiment, the first friction sleeve 41 and the second friction sleeve 42 are arranged side by side in the axial direction, and the outer end faces of the first friction sleeve 41 and the second friction sleeve 42 are opposed, while in this embodiment In an example, the second friction sleeve 42 is set outside the first friction sleeve 41, and the outer end surface of the first friction sleeve 41 is in contact with the inner end surface of the second friction sleeve 42. For the first friction sleeve 41 and the rotating screw The installation between 20 is the same as the first embodiment, the first fri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com