Preparation method of porous CuO-CeO2 dual-metallic oxide catalyst

A double metal oxide and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of high controllability, simple and easy method, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

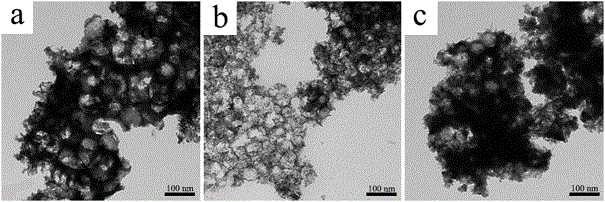

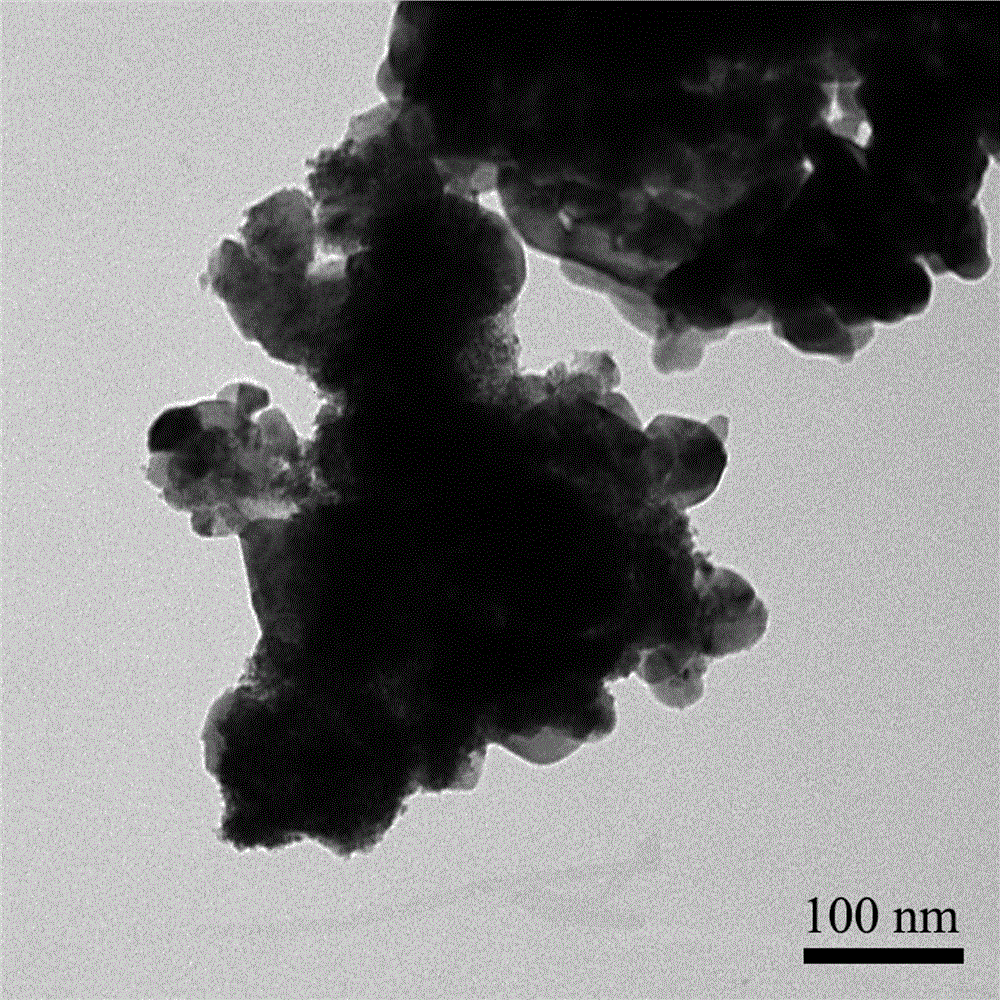

[0033] Take 0.5 g Ce(NO 3 ) 3 ·6H 2 O, 1.5 g Cu(NO 3 ) 2 ·3H 2 O. Dissolve 2 g of silica colloidal particles (particle size: 50 nm) in 5 ml of deionized water, heat to 150°C, and then add 400 mg of glycine. After the reaction is over, cool and wash with deionized water several times. Obtain CuO-CeO with silica template 2 double metal oxides;

[0034] CuO-CeO containing silica template 2 Double metal oxide, dispersed in 2 mol / L sodium hydroxide solution, stirred at 80°C for 8 h, centrifuged and rinsed briefly, then etched the silica template with 2 mol / L sodium hydroxide solution again, after the reaction , washed with deionized water and ethanol, and dried to obtain CuO and CeO with a pore size of 50 nm 2 Porous CuO-CeO with a molar ratio of 84:16 2 Bimetallic oxide catalysts.

Embodiment 2

[0036] Take 1 g Ce(NO 3 ) 3 ·6H 2 O, 1 g Cu(NO 3 ) 2 ·3H 2 O. Dissolve 2 g of silica colloidal particles (particle size: 50nm) in 5 ml of deionized water, heat to 150°C, and then add 400 mg of glycine. After the reaction, cool and wash with deionized water several times to obtain CuO-CeO with silica template 2 double metal oxides;

[0037] CuO-CeO containing silica template 2 Double metal oxide, dispersed in 2 mol / L sodium hydroxide solution, stirred at 80°C for 8 h, centrifuged and rinsed briefly, then etched the silica template with 2 mol / L sodium hydroxide solution again, after the reaction , washed with deionized water and ethanol, and dried to obtain CuO and CeO with a pore size of 50 nm 2 Porous CuO-CeO with a molar ratio of 64:36 2 Bimetallic oxide catalysts.

Embodiment 3

[0039] Take 1.5 g Ce(NO 3 ) 3 ·6H 2 O, 0.5 g Cu(NO 3 ) 2 ·3H 2 O. Dissolve 2 g of silica colloidal particles (particle size: 50 nm) in 5 ml of deionized water, heat to 150°C, and then add 400 mg of glycine. After the reaction is over, cool and wash with deionized water several times. Obtain CuO-CeO with silica template 2 double metal oxides;

[0040] CuO-CeO containing silica template 2 Double metal oxide, dispersed in 2 mol / L sodium hydroxide solution, stirred at 80°C for 8 h, centrifuged and rinsed briefly, then etched the silica template with 2 mol / L sodium hydroxide solution again, after the reaction , washed with deionized water and ethanol, and dried to obtain CuO and CeO with a pore size of 50 nm 2 Porous CuO-CeO with a molar ratio of 36:64 2 Bimetallic oxide catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com