Modified attapulgite material and its preparation and application methods

A technology for modifying attapulgite and attapulgite, which is applied in the field of uranium adsorption materials, and can solve problems such as limited adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples describe the present invention in more detail.

[0027] Put 1g of attapulgite in 15ml, 0.2mol / L HCl solution, ultrasonic 10-30min, filter, wash with deionized water, after filtration, dry at 80°C for 4h, heat up to 350°C for 2-10h, cool to room temperature , to obtain intermediate A;

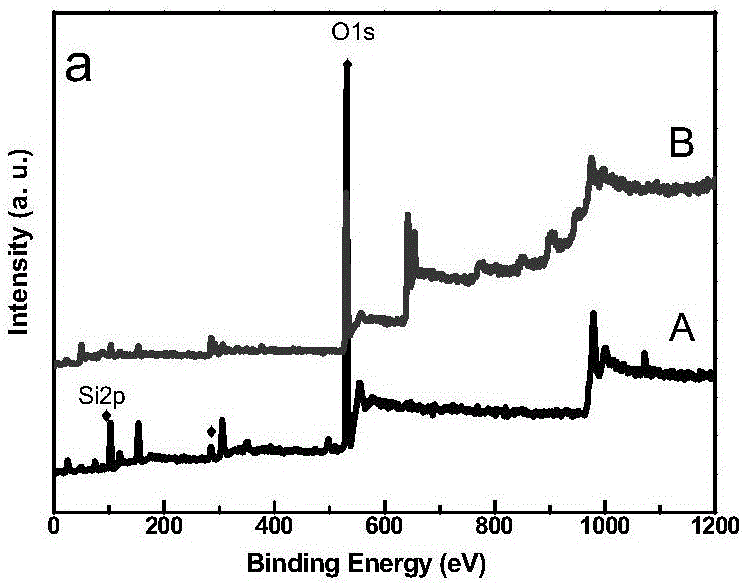

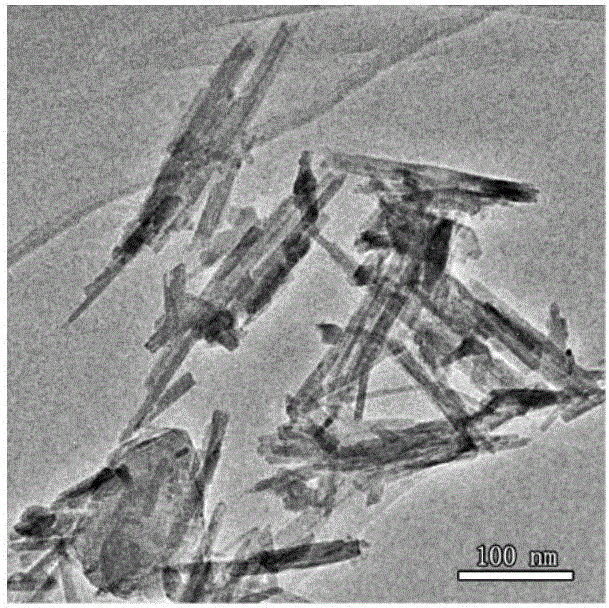

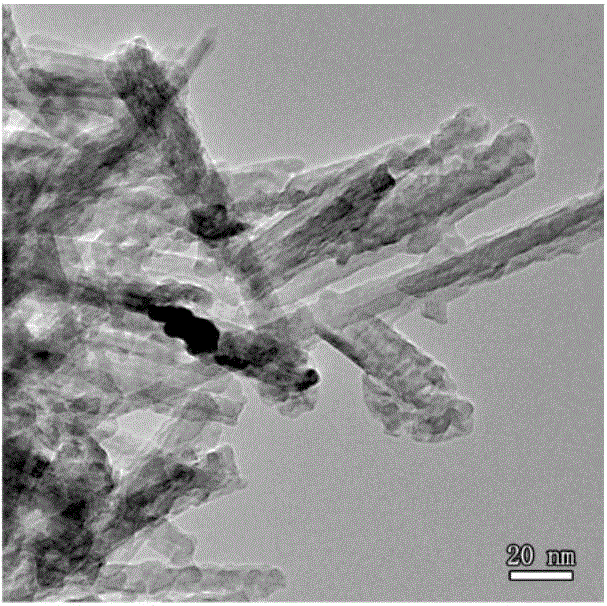

[0028] 0.2g MnCl 2 4H 2 Add O to 100mL isopropanol, dissolve and add intermediate A, stir and sonicate for 10-30min, stir for 30-120min, add 10-20mL0.04mol / L potassium permanganate solution, stir, reflux at 87°C for 30 -60min, cool to room temperature; suction filter, wash with 30% isopropanol solution until the liquid is clear; dry in an oven at 80-100°C for 1.5-2h to obtain modified attapulgite.

[0029] The characteristics of the above steps are described as follows:

[0030] (1) Acid activation: After the attapulgite is soaked in acid, the internal structure will be partially dissolved, and the undissolved part will act as a support, increasing the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com