Gas and dust separation device and vacuum cleaner

A technology for separating devices and air and dust, which is applied in vacuum cleaners, suction filters, household appliances, etc. It can solve the problems of reducing the air environment, damaging the motor, and reducing the service life of the motor, and achieves the effect of reducing cleaning frequency, increasing speed, and simple cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

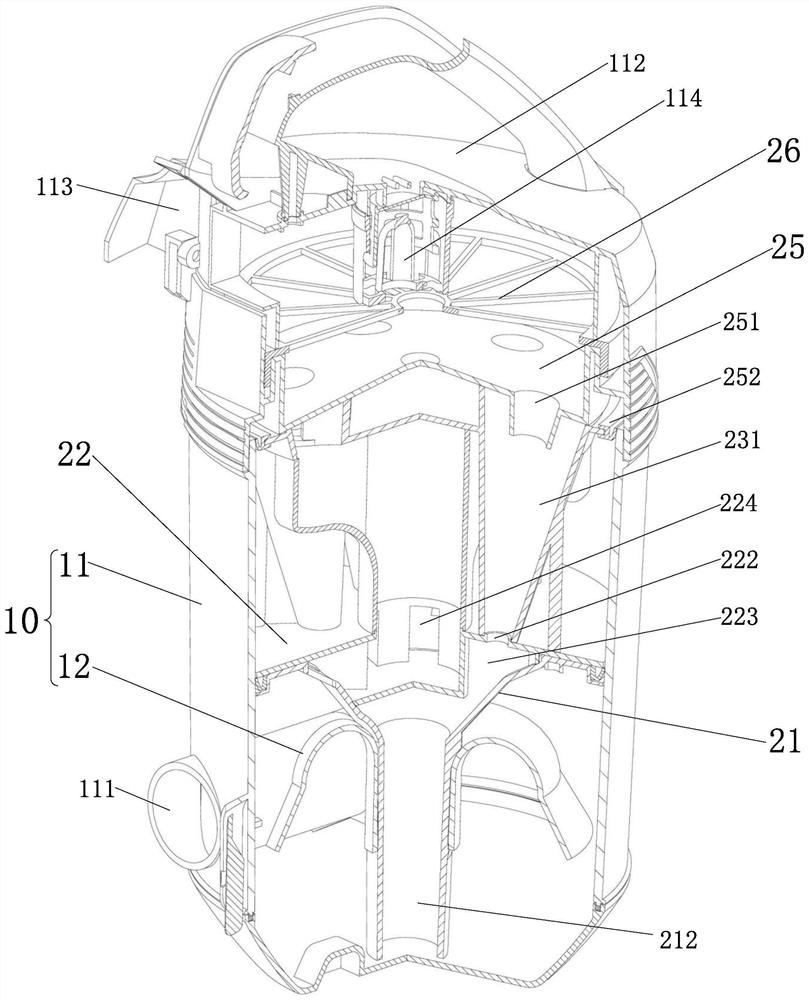

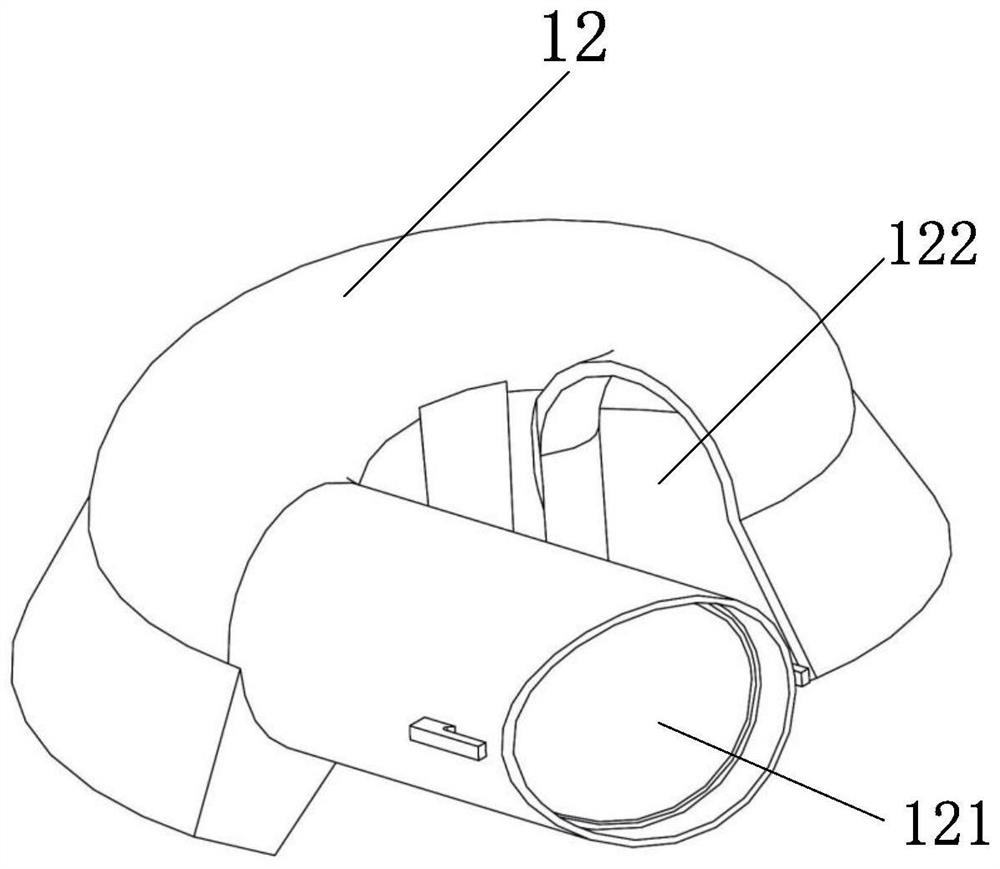

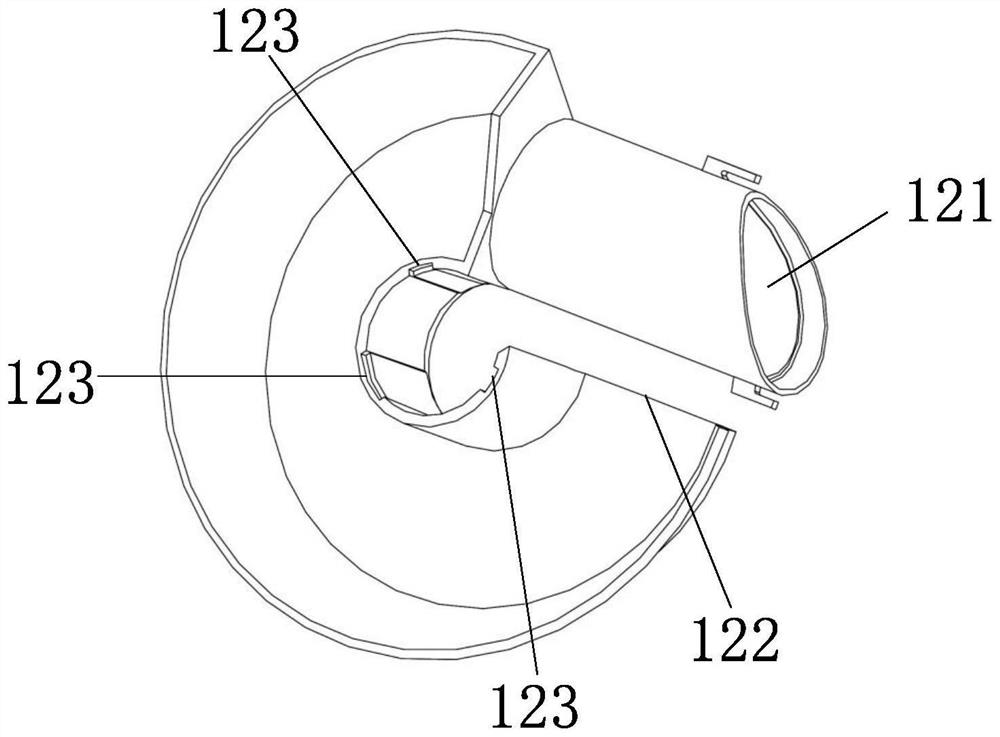

[0056] Such as figure 1 , Fig. 2(a), Fig. 2(b), Fig. 3(a) and Fig. 3(b), as shown, the embodiment of the present invention provides a kind of gas-dust separation device, comprising: dust cup 10 and gas-dust separation device 20. The dust cup 10 includes an outer cup 11 and an inner cup 12 having a cavity. The inner cup 12 is set in the outer cup 11 with the opening facing down; the outer cup 11 and the inner cup 12 are respectively provided with a connected first air inlet 111 and a second air inlet 121; the inner cup 12 is provided with a first outlet near the top. The tuyere 122; the gas-dust separator 20 includes a dust collection funnel 21, the dust collection funnel 21 is located inside the outer cup 11 and sealed and inserted above the inner cup 12; the dust collection funnel 21 is provided with a filter grid hole 211; wherein, the first air inlet 111. The second air inlet 121, the first air outlet 122, and the filter grid hole 211 form an airflow path; the inner cup 1...

Embodiment 2

[0071] On the basis of Embodiment 1, this embodiment provides a vacuum cleaner including the gas-dust separation device described in Embodiment 1. The vacuum cleaner is provided with a motor and its housing, an air-dust separation device and a floor mop. Wherein, the motor casing is provided with an air pumping power device, and the motor casing is provided with a gas inlet and a gas outlet; the outer cup 11 has a sealing cover on the top of the wind collecting plate 25 and the upper cover 112 above the filter cotton 26. The cover 112 is provided with a second air outlet 113 . Then, the second air outlet 113 of the upper cover 112 communicates with the gas inlet of the motor housing; the ground brush communicates with the first air inlet 111 of the outer cup 11 of the gas-dust separation device through a connecting piece.

[0072] The process of using the vacuum cleaner is: connect the suction power device to the power supply, hold the ground brush, and the suction power devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com