Automatic temperature-control ceramic pot suitable for electromagnetic stove

A technology for a ceramic pot and an electromagnetic cooker, which is applied in the field of kitchen appliances, can solve the problems of hurting users, cracking of the ceramic pot, bad taste of food, etc., and achieves the effect of avoiding cracking and reducing oil fumes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

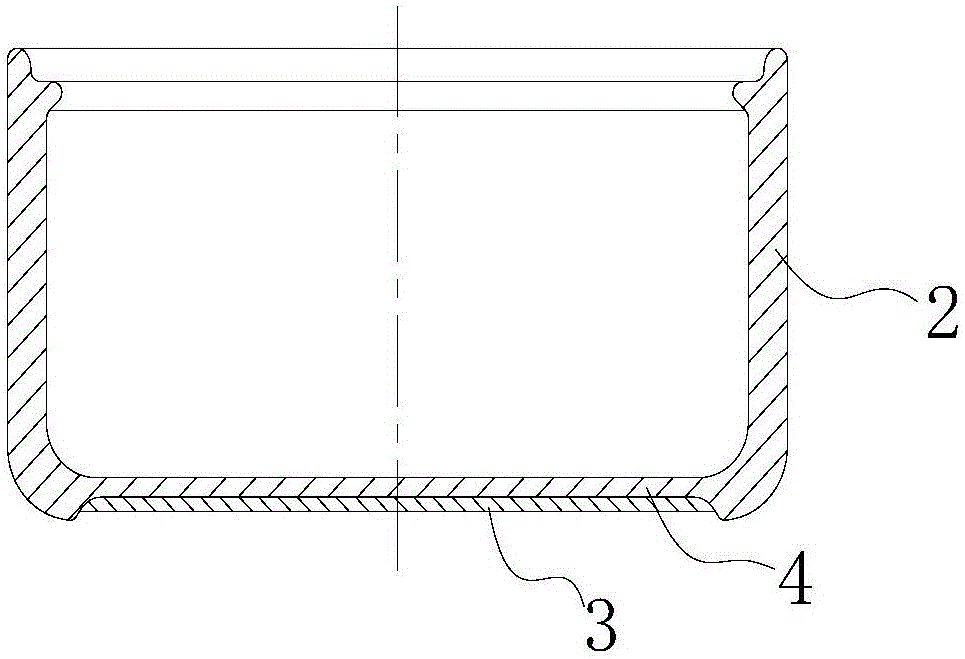

[0035] See figure 1 , an automatic temperature-controlling electromagnetic cooker applicable ceramic pot, said electromagnetic cooker applicable ceramic pot has a side wall 2 and a pot bottom 4, the side wall 2 and the pot bottom 4 are both provided with a ceramic layer; the pot bottom is provided with a layer of temperature control layer 3. The material of the temperature control layer is 1J36 alloy material with a Curie point of 200-230° C., and its composition is Mn≤0.6%, Si≤0.3%, 35%≤Ni≤37%, and the balance is Fe.

[0036] The temperature control layer 3 is arranged outside the ceramic layer at the bottom of the pan. The composition of the ceramic layer is aluminum silicate ceramics, the thickness of the side wall is 4 mm, the total thickness of the bottom of the pot 4 is 5 mm, wherein the thickness of the ceramic layer at the bottom of the pot is 4.5 mm, and the thickness of the temperature control layer is 0.5 mm. The area where the temperature control layer 3 is provi...

Embodiment 2

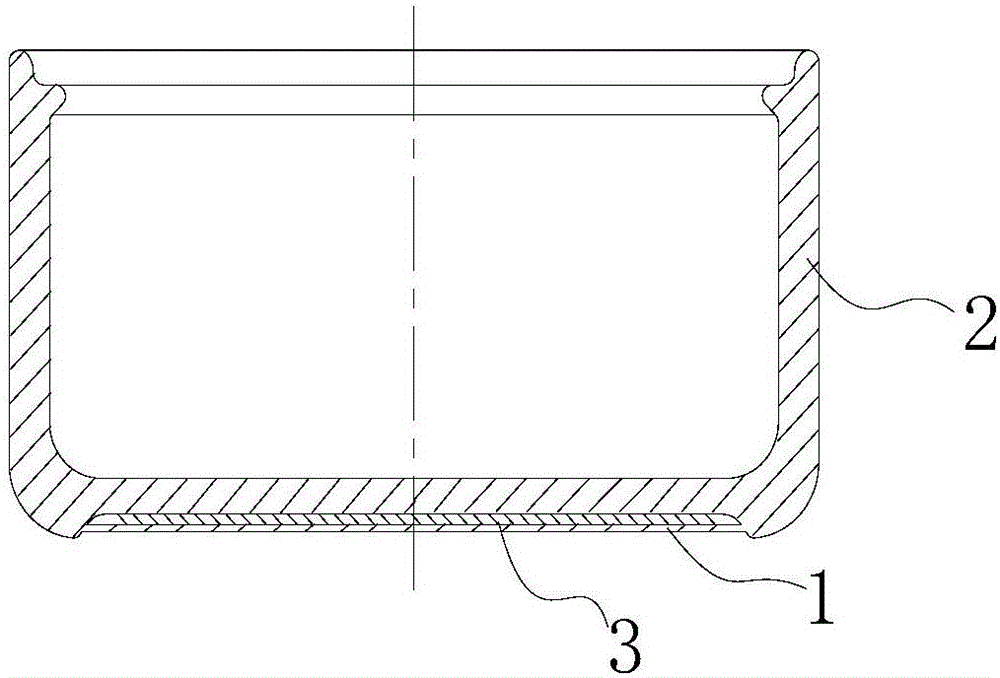

[0040] See figure 2 , an automatic temperature-controlling electromagnetic cooker applicable ceramic pot, said electromagnetic cooker applicable ceramic pot has a side wall 2 and a pot bottom 4, and both the side wall and the pot bottom are provided with a ceramic layer 1; the pot bottom has a sandwich structure, and the ceramic layer 1 A temperature control layer 3 is arranged between them. The material of the temperature control layer is 1J36 alloy material with a Curie point of 200-230° C., and its composition is Mn≤0.6%, Si≤0.3%, 35%≤Ni≤37%, and the balance is Fe.

[0041] The temperature control layer 3 is arranged outside the ceramic layer at the bottom of the pan. The composition of ceramic layer 1 is YSZ (Y 2 o 3 Stabilized ZrO 2 ) ceramics, the thickness of the side wall is 4mm, the total thickness of the bottom of the pot is 5mm, wherein the thickness of the ceramic layer at the bottom of the pot is 4mm, and the thickness of the temperature control layer is 1mm....

Embodiment 3

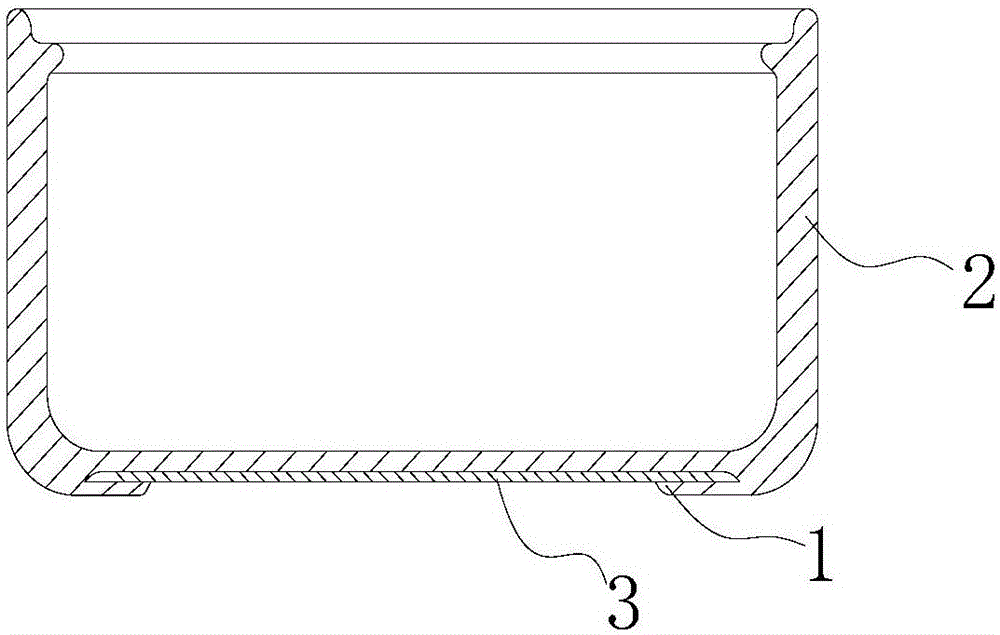

[0044] An automatic temperature control electromagnetic cooker is applicable to a ceramic pot, and the applicable ceramic pot for the electromagnetic cooker has a side wall 2 and a pot bottom, and both the side wall and the pot bottom are provided with a ceramic layer 1; the pot bottom is provided with a temperature control layer 3. The material of the temperature control layer is 1J36 alloy material with a Curie point of 200-230°C.

[0045] The temperature control layer 3 is arranged outside the ceramic layer at the bottom of the pan. The composition of ceramic layer 1 is Si 3 N 4 Ceramic, the thickness of the side wall is 5mm, the total thickness of the bottom of the pot is 6mm, wherein the thickness of the ceramic layer at the bottom of the pot is 5.7mm, and the thickness of the temperature control layer is 0.3mm. The area where the temperature control layer 3 is provided at the bottom of the pan is concave, and there is a height difference of 0.5 mm between the outer edg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com