Alloy electrode for skutterudite thermoelectric element and preparation method thereof

A technology of alloy electrodes and thermoelectric elements, which is applied in the manufacture/processing of thermoelectric devices, parts and components of thermoelectric devices, etc., and can solve problems such as difficult electrode preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

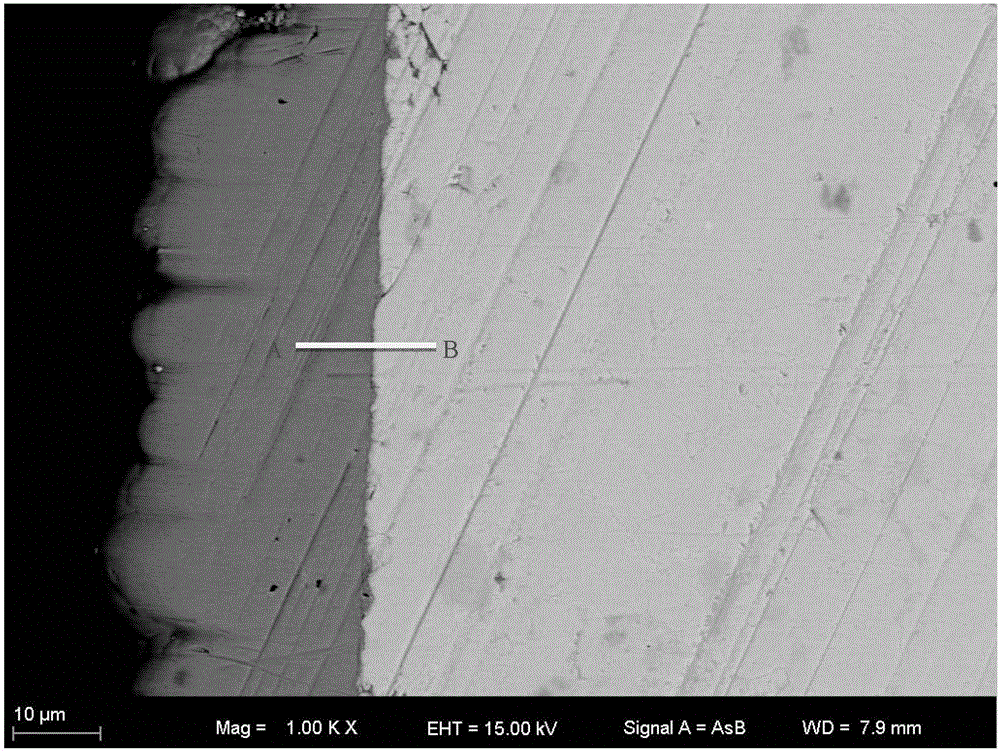

[0066]Preparation of Ni(Mo) alloy electrode at the low temperature end of skutterudite thermoelectric power generation element by electroplating method: P-type skutterudite powder is installed in a graphite mold, and the bulk material is prepared by SPS sintering, and the sintered skutterudite block is prepared The surface is polished clean and smooth with sandpaper, and the method for preparing Ni(Mo) alloy electrodes according to the above-mentioned electroplating method is first pretreated before plating, and then immersed in the plating solution to deposit electrodes. The preparation conditions are: the concentration of Ni ions in the plating solution is 60g / L, the concentration of Mo ions is 20g / L, the temperature is 35°C, and the current density is 10A / dm 2 , Plating time is 40min. The mole percentage of Mo in the prepared Ni(Mo) alloy electrode at the low temperature end is about 19%, and the thickness of the alloy electrode is about 25 μm;

[0067] At this time, the ...

Embodiment 2

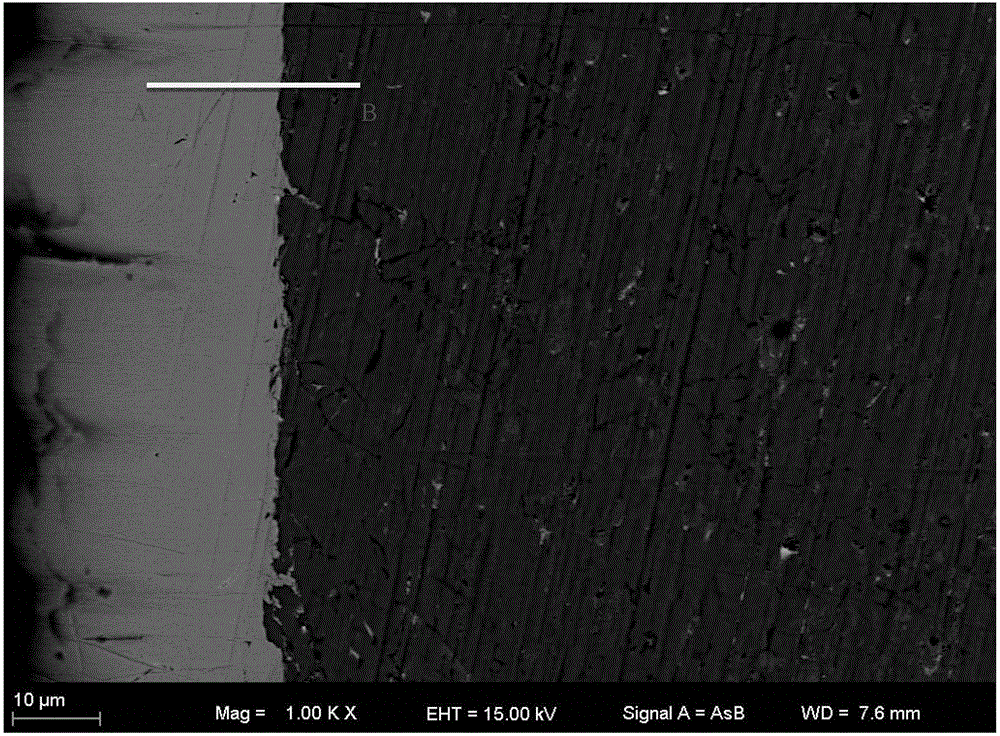

[0069] Preparation of Ni(Mo) alloy electrodes at the high temperature end of skutterudite thermoelectric power generation elements by electroplating: Put the skutterudite powder material into the graphite mold, then spread Ti on the skutterudite as a transition layer, and prepare thermoelectric elements by SPS , the surface of the sample prepared by sintering was polished clean and smooth with sandpaper. At the high temperature end, that is, the surface of the transition layer Ti, the Ni(Mo) alloy electrode was prepared according to the above-mentioned electroplating method, firstly pretreated before plating, and then immersed in the plating solution to deposit the electrode , the preparation conditions are: the concentration of Ni ions in the plating solution is 60g / L, the concentration of Mo ions is 20g / L, the temperature is 35°C, and the current density is 10A / dm 2 , Plating time is 40min. The mole percentage of Mo in the prepared high-temperature end Ni(Mo) alloy electrode...

Embodiment 3

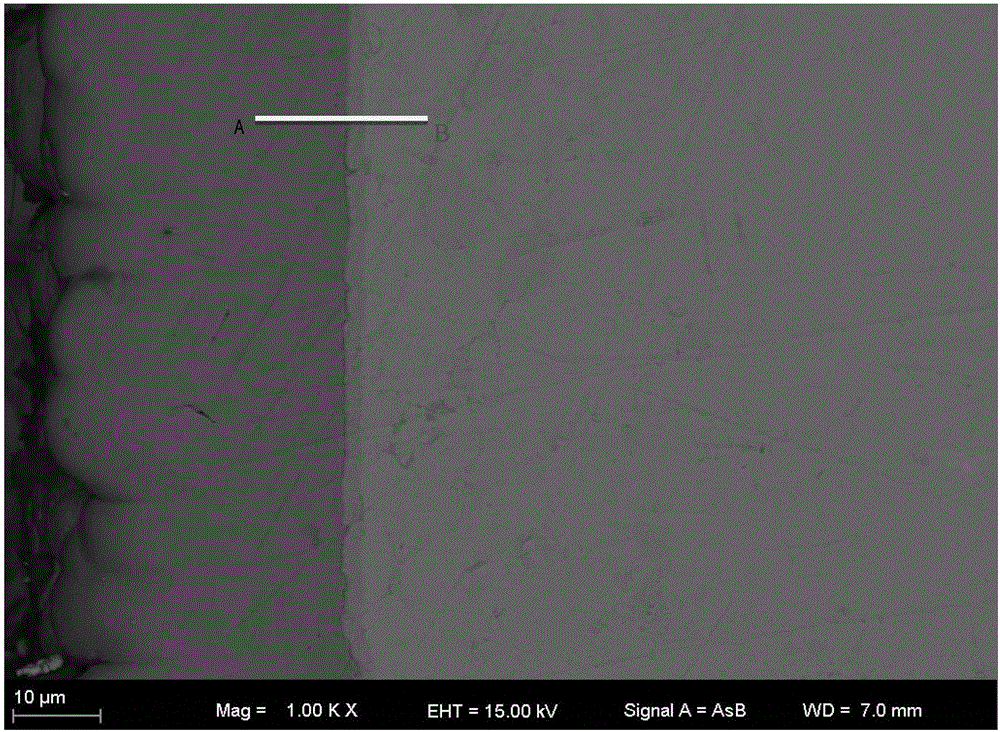

[0072] Preparation of Ni(W) alloy electrodes at the high and low temperature end of skutterudite thermoelectric generation elements by electroplating: Put the skutterudite powder material into the graphite mold, then spread Ti powder on the skutterudite as a transition layer, and prepare it by SPS For thermoelectric elements, the surface of the sample prepared by sintering is polished clean and smooth with sandpaper, and the Ni(W) alloy electrode is prepared on the surface of the low-temperature end, that is, the surface of the skutterudite matrix material according to the above-mentioned electroplating method, first pre-treated before plating, and then immersed in the plating solution Deposit the electrode in the middle; on the high temperature end, that is, the surface of the transition layer Ti, prepare the Ni(W) alloy electrode according to the above-mentioned electroplating method, first undergo pre-plating pretreatment, and then immerse in the plating solution to deposit t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com