Hollow micro-sphere possessing multilayer cobaltous sulfide/cobaltous oxide shell and preparation method and application thereof

A technology of microspheres and cobalt oxide, which is applied in the preparation of microspheres, microcapsule preparations, and hybrid/electric double-layer capacitor manufacturing. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

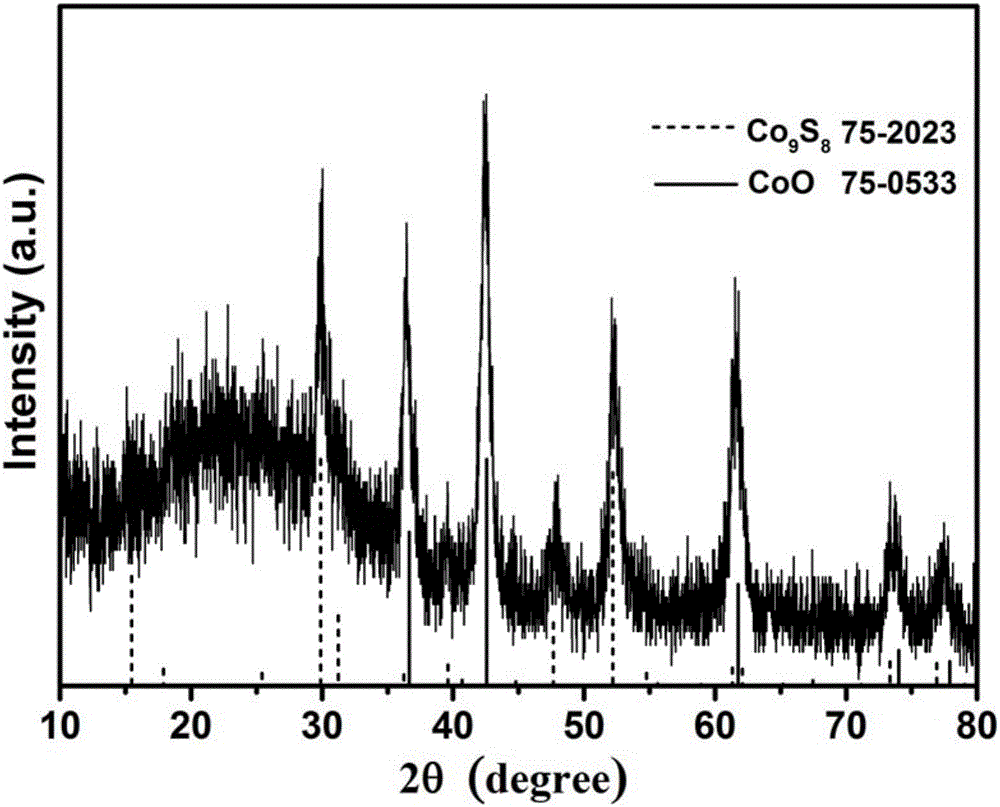

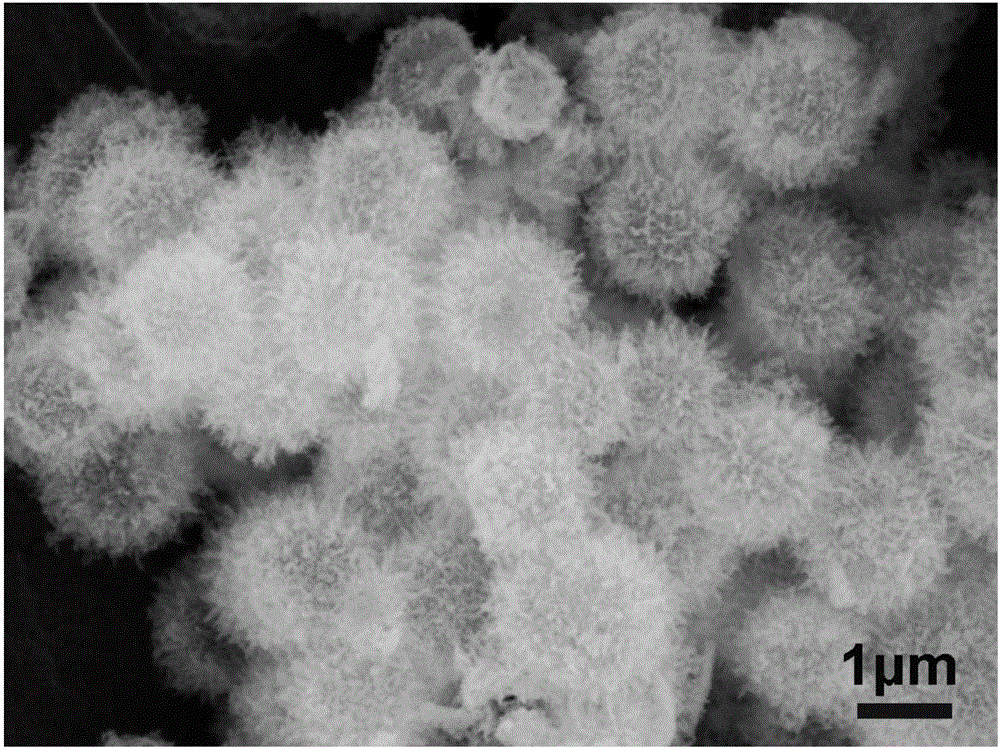

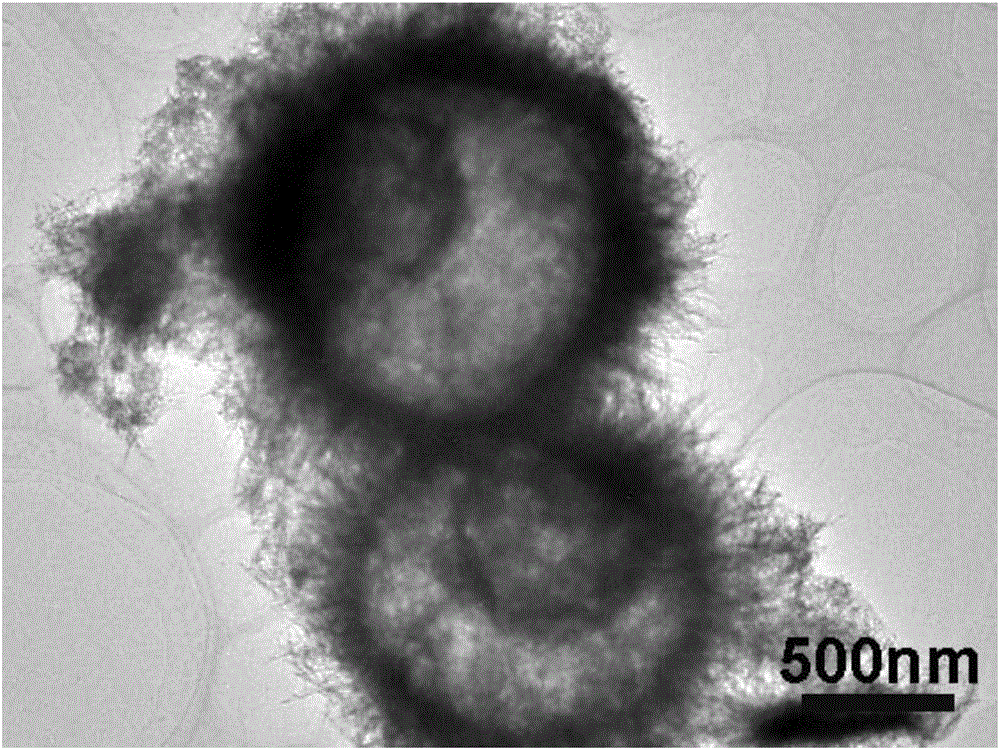

[0028] 50 mg of carbon spheres with a diameter of 1 μm were ultrasonically dispersed in a mixed solution of 100 ml of water and ethanol (volume ratio 1:1), and 0.2 g of Co(NO 3 ) 2 ﹒ 6H 2 O and 1g CO(NH 2 ) 2 Mixed evenly, the mixed solution was stirred at 80°C for 12h, the obtained product was centrifuged and washed with deionized water and ethanol, and then dried in a constant temperature oven at 60°C for 12h. The obtained powder was heat-treated in air at 500°C for 2h, and the heating rate was 3°C / min. Income Co 3 o 4 The hollow spheres are mixed with sulfur powder (Co / S molar ratio is 1:1), transferred to a tube furnace, and roasted at 400°C for 4 hours in an argon atmosphere to obtain Co 9 S 8 / CoO hollow spheres with multilayer core-shell structure. Adopt Japanese science D / max-2500 type X-ray diffraction analyzer to analyze gained sample, obtained result is as follows figure 1 shown. The morphology and particle size of the sample were observed with a Nova Nan...

Embodiment 2

[0030] 50 mg of carbon spheres with a diameter of 700 nm were ultrasonically dispersed in a mixed solution of 100 ml of water and methanol (volume ratio 1:1), and 0.2 g of Co(NO 3 ) 2 ﹒ 6H 2 O and 1g CO(NH 2 ) 2 Mixed evenly, the mixed solution was stirred at 80°C for 12h, the obtained product was centrifuged and washed with deionized water and ethanol, and then dried in a constant temperature oven at 60°C for 12h. The obtained powder was heat-treated in air at 500°C for 2h, and the heating rate was 3°C / min. Income Co 3 o 4 The hollow spheres were mixed with sulfur powder (Co / S molar ratio was 1:1) and transferred to a tube furnace, and fired at 400°C for 4h in an argon atmosphere.

Embodiment 3

[0032] 50 mg of carbon spheres with a diameter of 700 nm were ultrasonically dispersed in a mixed solution of 100 ml of water and ethanol (volume ratio 1:1), and 0.5 g of Co(NO 3 ) 2 ﹒ 6H 2 O and 1.5g CO(NH 2 ) 2 Mixed evenly, the mixed solution was stirred at 80°C for 6h, the obtained product was centrifuged and washed with deionized water and ethanol, and then dried in a constant temperature oven at 60°C for 12h. The obtained powder was heat-treated in air at 500°C for 2h, and the heating rate was 3°C / min. Income Co 3 o 4 The hollow spheres were mixed with sulfur powder (Co / S molar ratio was 1:3) and transferred to a tube furnace, and fired at 400°C for 4h in an argon atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com