Electromagnetic shielded communication cables for rail transit

A technology for rail transit and communication cables, which is applied in communication cables, insulated cables, cables, etc. It can solve the problems that the flame-retardant sheath cannot effectively block heat transfer, the cable electromagnetic shielding performance is not good, and the function of transmitting information is lost. Achieve good mechanical properties, shielding, high magnetic permeability, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] refer to figure 1As shown, a communication cable is disclosed in Embodiment 1, and its structure includes from outside to inside: a low-smoke halogen-free outer sheath 10, a first refractory layer 20, a high magnetic permeability steel tape armor layer 30, a low-smoke Halogen-free inner sheath 40, second refractory layer 50, aluminum sheath 60, PE heat insulation layer 70, water blocking layer 80, aluminum-plastic composite tape 90, shielding layer 100, several stranded insulated core wires 101, the above stranded The insulated core wire 101 is covered by a wrapping polyester tape 103, the above-mentioned stranded insulated core wire 101 and the above-mentioned wrapped polyester tape 103 are filled with ointment 104, and the outside of the above-mentioned stranded insulated core wire 101 is covered with an insulating layer , the above-mentioned shielding layer 100 is used as the first layer of shielding for the core wire of the communication cable, and the above-mention...

Embodiment 2

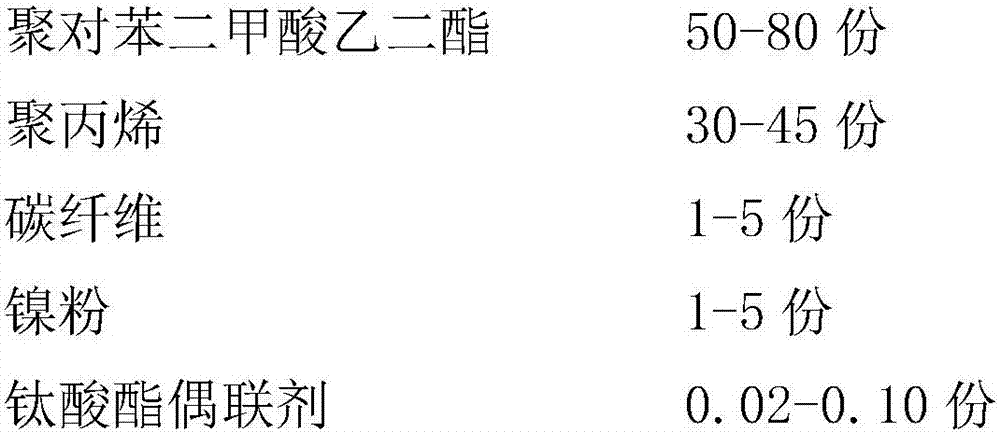

[0060] The structure of the communication cable in embodiment 2 is the same as in embodiment 1, and the polyester film material formula is as shown in table 4:

[0061] The material formula of polyester film in table 4 embodiment 2

[0062] components Content (parts by weight) polyethylene terephthalate 65 Polypropylene 38 carbon fiber 3 nickel powder 3 Titanate coupling agent 0.06

[0063] Wherein, the melt index of the above-mentioned polypropylene is 3.0g / min, the above-mentioned carbon fiber is PAN-based carbon fiber, the length of the above-mentioned carbon fiber is 7 μm, the particle size of the above-mentioned nickel powder is 4 μm, and the above-mentioned titanate coupling agent includes titanate coupling Agent NDZ-102 and titanate coupling agent TMC-TTS.

[0064] Titanate coupling agent NDZ-102 carries out surface treatment to above-mentioned carbon fiber, and the consumption of titanate coupling agent NDZ-102 is 1% of th...

Embodiment 3

[0078] The structure of the communication cable in embodiment 3 is the same as in embodiment 1, and the polyester film material formula is as shown in table 7:

[0079] The material formula of polyester film in table 7 embodiment 2

[0080] components Content (parts by weight) polyethylene terephthalate 65 Polypropylene 38 carbon fiber 3 nickel powder 3 Titanate coupling agent 0.06

[0081] Wherein, the melt index of the above-mentioned polypropylene is 3.0g / min, the above-mentioned carbon fiber is PAN-based carbon fiber, the length of the above-mentioned carbon fiber is 7 μm, the particle size of the above-mentioned nickel powder is 4 μm, and the above-mentioned titanate coupling agent includes titanate coupling Agent NDZ-102 and titanate coupling agent TMC-TTS.

[0082] Titanate coupling agent NDZ-102 carries out surface treatment to above-mentioned carbon fiber, and the consumption of titanate coupling agent NDZ-102 is 1% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com