Mechanism motion accuracy reliability allocation method considering abrasion

A technology of mechanism movement and distribution method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of running errors and take into account at the same time, and achieve the effect of ensuring the reliability of the mechanism and meeting the requirements of reliability indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

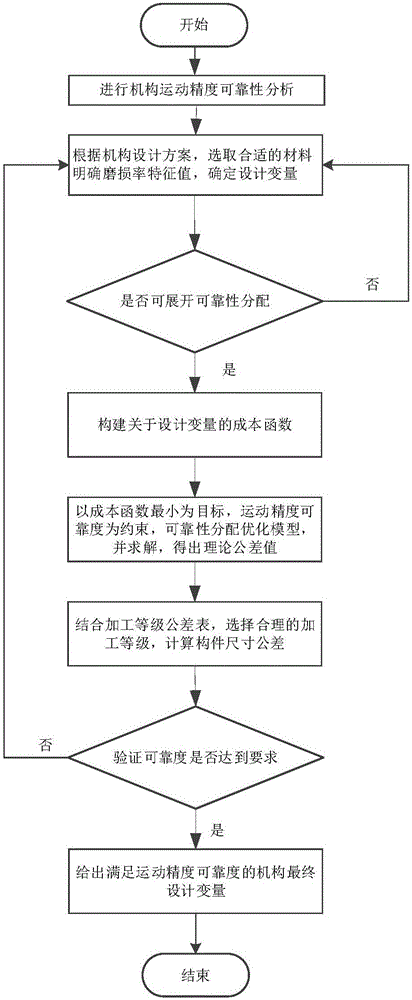

Method used

Image

Examples

Embodiment

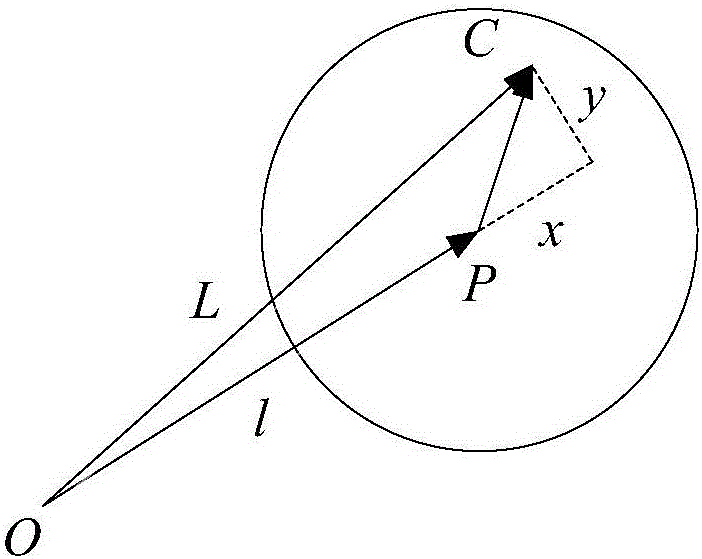

[0122] Based on the above theory Figure 4 The slider crank mechanism is designed for reliability distribution or precision.

[0123] like Figure 4 As shown, the crank-slider mechanism includes a crank OA, a connecting rod AB, and a slider, point O is the same height as point B on the slider, the length r of the crank OA is 20cm, and the length g of the connecting rod AB is g=40cm , α is the angle through which the crank OA rotates. If the rotation angle α=90° after working for 20kh, the required mechanism accuracy reliability R 0 =0.942, allowable output displacement error eigenvalue (μ 0 ,σ 0 )=(0.95,0.01)(cm), taking the stable stage of wear as an example, assuming that the wear rate characteristic value of the selected component material at point O and point A (μ v ,σ v )=(0.06,0.0033)(cm / kh), the gap at B can be ignored. Try to determine the eigenvalues of the gaps at points O and A and the dimensional tolerances of the components.

[0124] Step 1. Carry out re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com