Small-particle size rubber powder production device

A production device and rubber powder technology, which is applied in the fields of recycling technology, grain processing, mechanical material recycling, etc., can solve the problems of uncommon popularization and application, large investment, complicated process technology, etc., achieve wide applicability and ensure processing quality , the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

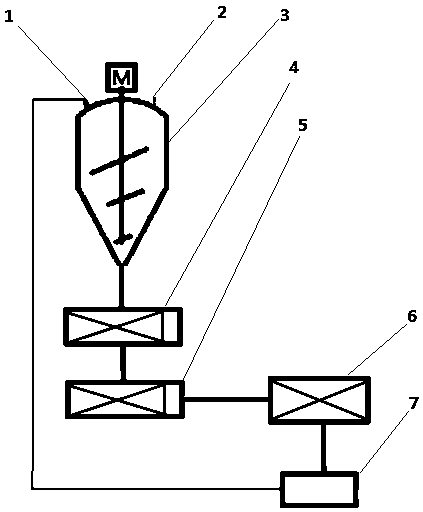

[0031] Thousand tons of small particle size rubber powder production equipment, including the material mixer (3) is a stainless steel stirring kettle with a 3 cubic meter conical bottom, and the shear crusher one (4) is a DSJTM-50SJM secondary shear colloid mill. The second cutting crusher (5) DSJTM-50SJM secondary shearing colloidal mill, the solid-liquid separator (6) is a new MKWL-5 drum screen microfiltration filter equipment, and the circulating pump (7) is a DN50 stainless steel pipeline pump.

[0032] The outlet pipe at the bottom of the material mixer (3) is connected with the feed inlet of the shear crusher one (4); the outlet pipe of the shear crusher one (4) is connected with the inlet of the shear crusher two (5); the shear crusher two (5) The outlet pipe is connected with the inlet of the solid-liquid separator (6); the liquid water outlet at the lower part of the solid-liquid separator (6) is connected with the inlet of the water circulation pump (7); the outlet of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com