Method for measuring depth of superhard abrasive impact toughness sample tube

An impact toughness, super-hard abrasive technology, applied in measuring devices, using repetitive force/pulse force to test the strength of materials, analyzing materials, etc. In-depth test accuracy, affecting product production and actual use, etc., to achieve the effect of accurate performance indicators and product classification, convenient measurement, and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in combination with specific embodiments.

[0013] The main steps of the synthetic diamond impact toughness test are: put 2 ct (0.4 g) of the sample to be tested and a steel ball (φ8) into the impact sample tube, cover it and clamp it on the impact toughness tester. Turn on the impact toughness tester and measure the unbroken rate after a certain number of impacts. The unbroken rate is corrected by the standard sample, which is the impact toughness value of the sample.

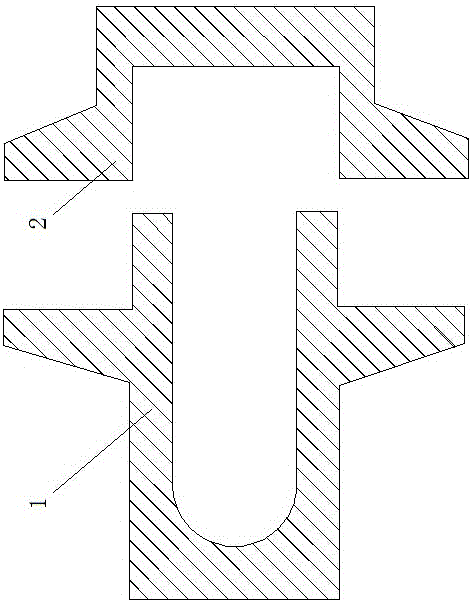

[0014] see figure 1 , a superabrasive impact toughness sample tube, comprising a sample tube 1 and a sample tube cover 2, is applied to the impact toughness test of artificial diamond, and the method for measuring its depth comprises the following steps:

[0015] 1) Clean the sample tube to be measured with alcohol, dry it and place it under the temperature and humidity conditions required for measurement for more than 30 minutes;

[0016] 2) Take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com