Reluctance Electromagnetic Active Vibration Absorber

A vibration absorber, magnetoresistive technology, applied in the direction of shock absorbers, magnetic springs, springs/shock absorbers, etc., can solve the problems of volume and mass reduction, nonlinearity, etc., to achieve convenient disassembly and assembly, strong engineering applicability , the effect of solving nonlinear problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

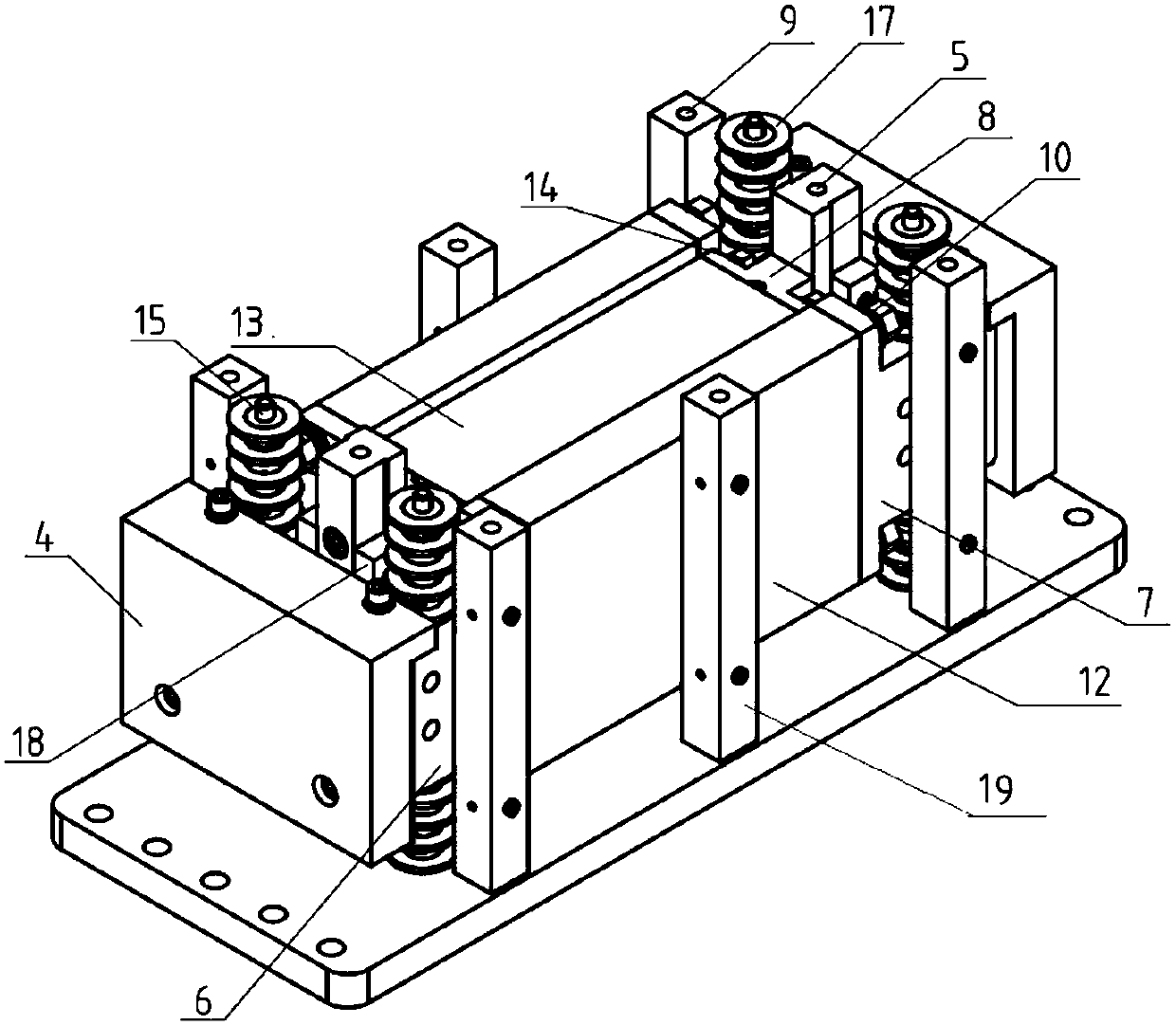

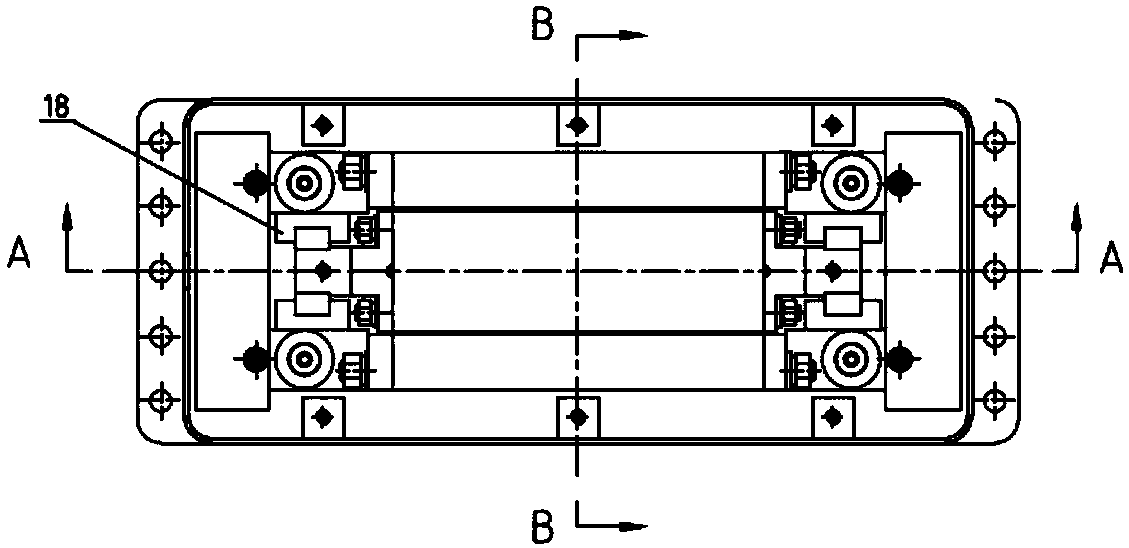

[0027] Referring to the accompanying drawings, a reluctance type electromagnetic active vibration absorber includes: a housing composed of a lower mounting plate 1 of the vibration absorber, a cover 2 of the vibration absorber and an upper mounting plate 3 of the vibration absorber, and a mover assembly located inside the housing and stator assembly;

[0028] The mover assembly includes: two mover silicon steel sheets 12 with permanent magnets 11 embedded in the central groove of the end face; the two mover silicon steel sheets 12 are placed parallel to each other on the lower mounting plate 1 of the vibration absorber, and are installed with the lower vibration absorber. The plate 1 is vertical, and the end embedded with the permanent magnet 11 is opposite to each other. The two sides of each mover silicon steel sheet 12 respectively pass through the mover fixing screw 10 and the left fixed plate 6 of the mover silicon steel sheet, and the right fixed plate of the mover silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com