Preparing method for amido-modified nanometer fiber material for carbon dioxide adsorption

A nanofiber, carbon dioxide technology, applied in chemical instruments and methods, plant fibers, fiber types, etc., can solve the problem of easy pulverization of granular porous materials, and achieve rich pore structure, good continuity, and avoid secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

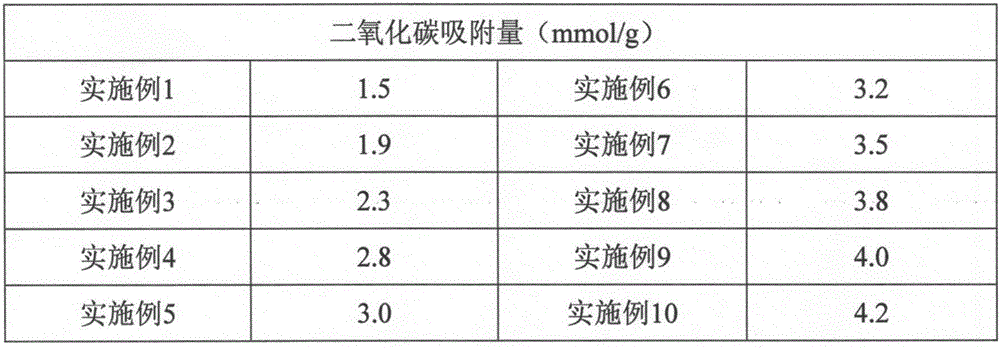

Examples

Embodiment 1

[0022] A method for preparing an amino-modified nanofiber material for carbon dioxide adsorption, the specific steps are:

[0023] At room temperature of 25°C, 0.5g of polyethersulfone was dissolved in 9.5g of dimethyl sulfoxide in a stirred tank with a rotation speed of 100rpm to obtain a polyethersulfone solution with a mass fraction of 5% for electrospinning. Spinning raw materials were added to the electrospinning device, and electrospinning was carried out under the conditions of static voltage of 10kV, syringe pump flow rate of 0.3mL / h, and a distance of 6cm between the spinneret and the receiving screen to obtain polyethersulfone nanofiber template materials.

[0024] Dissolve polyethyleneimine in methanol to make a methanol solution of polyethyleneimine with a concentration of 1mg / mL, and immerse the prepared polyethersulfone nanofiber template material into the prepared polyethyleneimine with a concentration of 1mg / mL. In the methanol solution of amine, stir for 30 mi...

Embodiment 2

[0026] A method for preparing an amino-modified nanofiber material for carbon dioxide adsorption, the specific steps are:

[0027] At room temperature of 25°C, 1 g of cellulose acetate was dissolved in 9 g of acetone in a stirred tank at a speed of 300 rpm to obtain a 10% electrospinning raw material cellulose acetate solution, and the obtained electrospinning raw material was added to the electrospinning In the silk device, under the conditions of static voltage of 10kV, syringe pump flow rate of 0.5mL / h, and distance between spinneret and receiving screen of 10cm, electrospinning was carried out to obtain polyethersulfone nanofiber template material.

[0028] Dissolve polyacrylamide in ethanol, prepare a polyacrylamide ethanol solution with a concentration of 2 mg / mL, immerse the prepared cellulose acetate nanofiber template material in a polyacrylamide ethanol solution with a concentration of 2 mg / mL, and rotate In the evaporator, stir for 40 minutes at a temperature of 32°...

Embodiment 3

[0030] A method for preparing an amino-modified nanofiber material for carbon dioxide adsorption, the specific steps are:

[0031] At room temperature of 25°C, 0.5g of polystyrene was dissolved in 9.5g of dimethyl sulfoxide in a stirred tank with a rotation speed of 200rpm to obtain a 5% electrospinning raw material polystyrene solution. Spinning raw materials were added to the electrospinning device, and electrospinning was carried out under the conditions of static voltage of 15kV, injection pump flow rate of 1mL / h, and a distance of 10cm between the spinneret and the receiving screen to obtain polystyrene nanofiber template materials.

[0032] Dissolve diethanolamine in methanol, prepare a methanol solution of diethanolamine with a concentration of 10 mg / mL, immerse the prepared polystyrene nanofiber template material in a methanol solution with a concentration of 10 mg / mL of diethanolamine, and place in a rotary evaporator , stirred for 45 minutes at a temperature of 33°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com